Another option for modifying the current extruder is to replace the 4-way multiplex and bowden setup with a direct extruder. This is like converting the MM setup back to the older single-extruder setup. However, I don't really want to revert my printer; instead I want an easily swappable direct extruder for when it makes sense (e.g. printing flexible material). Besides, the original Prusa extruder was never great for flexible materials anyway.

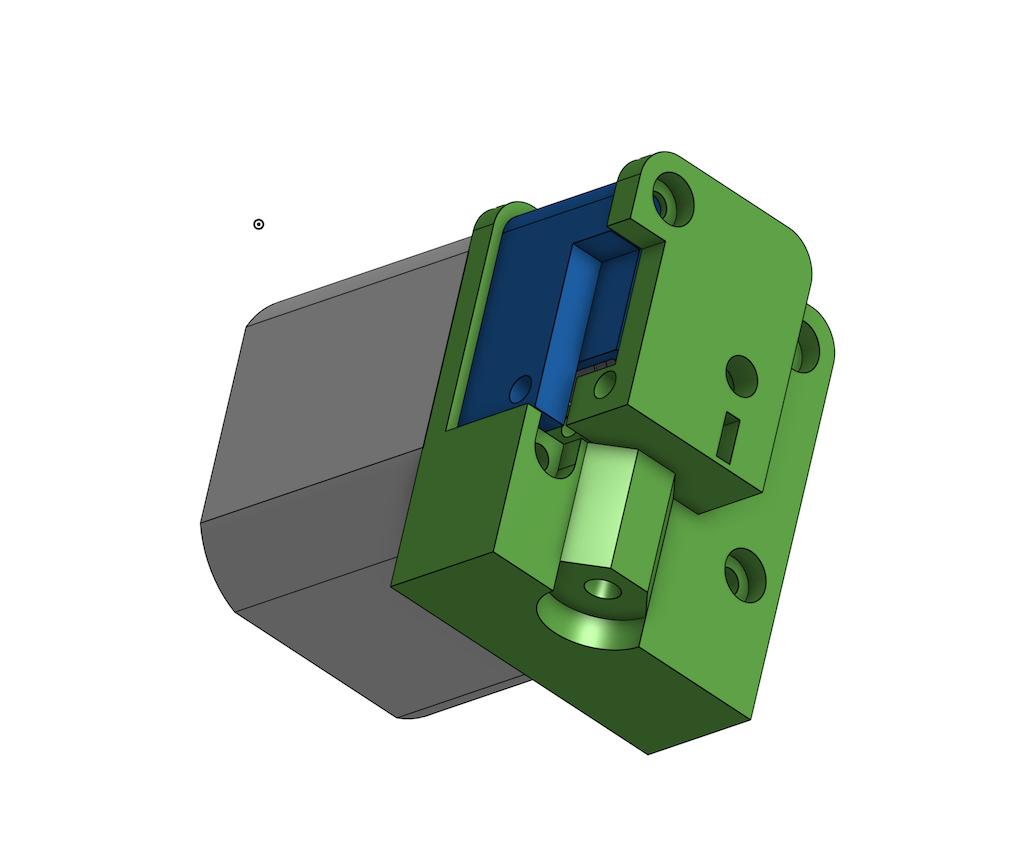

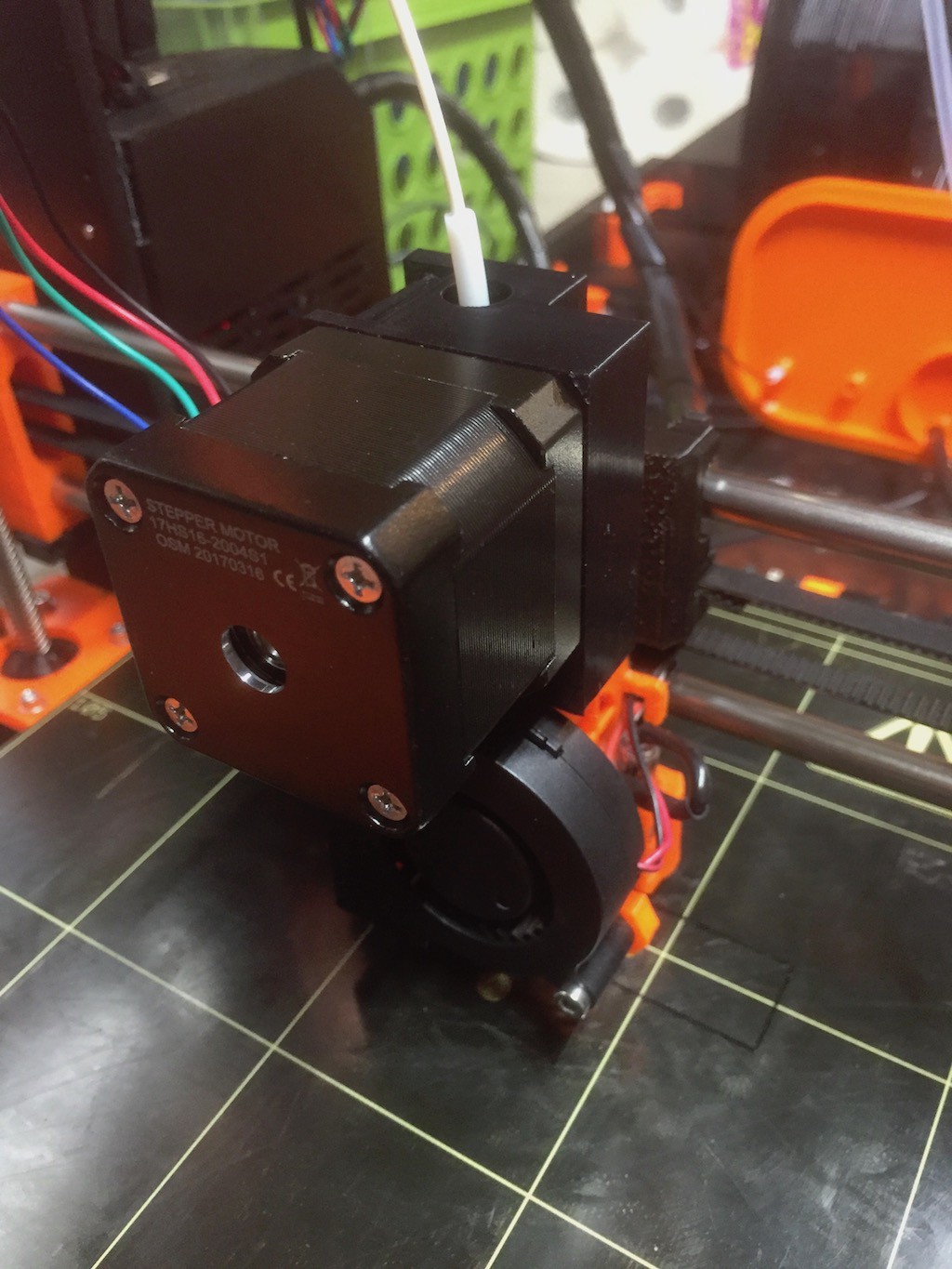

The above design is based on the previous bowden extruders I created, but adapted to fit into the slot left when the multi-material splitter is removed. The extruder slides into place and is secured using the same bolt. Short pieces of PTFE tubing are inserted into the top and bottom to provide a smooth path into the extruder and out to the hotend. The picture below shows the extruder mounted on the printer.

For printing single materials, this extruder has a couple of advantages: first, it will print flexible filament (such as NinjaFlex) at full speed, something I never would do before; and second, for normal filament I can greatly decrease the retraction and maintain or improve print quality over the bowden setup. Because of that, this has actually become my standard print setup when I don't need to use support material.

Of course, I did need to sacrifice one of the stepper motors to this design, leaving only 3 for the multi-material setup. However, because I mainly use the printer for either single or dual material printing, I don't find this a big loss.

Tim Wilkinson

Tim Wilkinson

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.