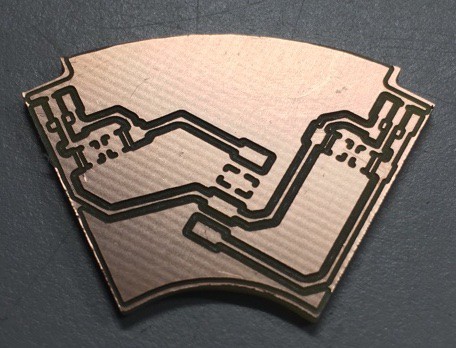

I finally got around re-designing the base plate. As I indicated in my last post, it needed to be a bit higher and it needed some hole to mount the MPG. What I also wanted to do was to create a custom PCB for attaching the hall sensor and the wires. It was a while back since I using EagleCad and was pleased to find that this was now owned by Autodesk and integrates nicely with Fusion360. I created a PCB in fusion in the shape of the space underneath the MPG and linked this to EagleCad. After I was finished with designing the PCB in EagleCad, I used FlatCAM and AutoLeveler to generate the G-Code. A couple of tests (read failures) later I was able to get a reasonable PCB using one of my cheap 60 degree engraving bits.

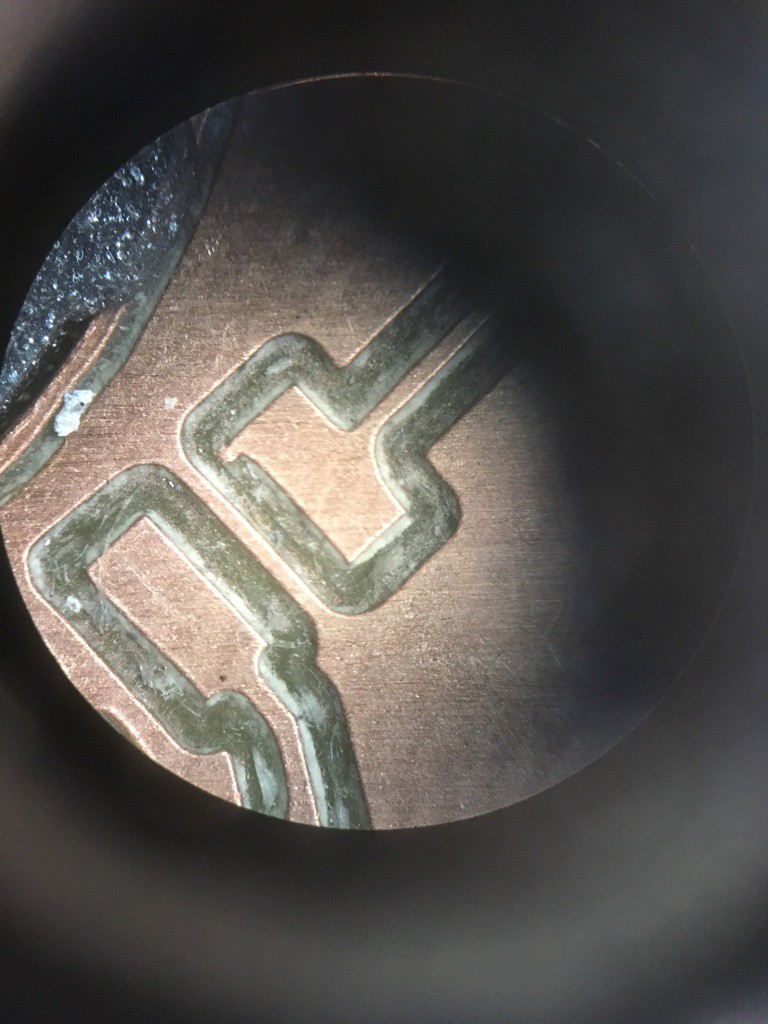

Even under the microscope it looks pretty, no rough edges at all.

When I mounted the hall sensors I noticed that I had the pins of the sensors swapped, so back to EagleCad. Since I needed to change things anyway, I also moved and rotated the pads for the wires.

So, all I now need to do is make 2 more and I can start using my very own MPGs :)

the.wretch

the.wretch

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.