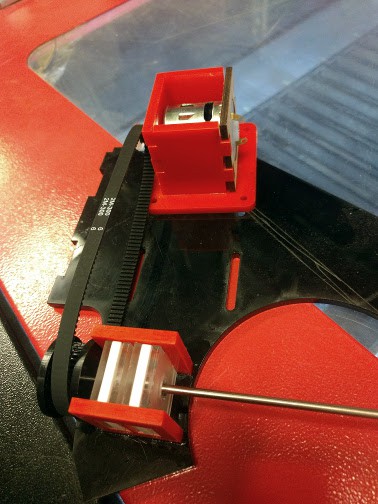

Check out my tensioning slots on the base plate:

That's a pretty common way to allow a builder to slide the pulleys back and forth until tension on the belt is juuuuust right.

But wait, what's this?

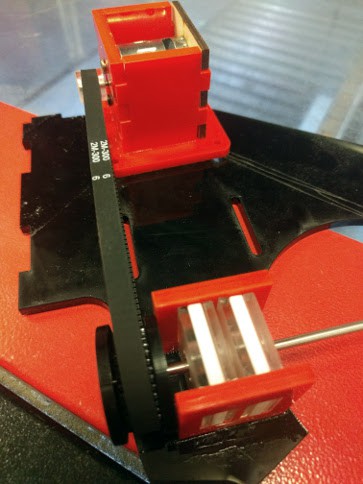

That only works if you calculate your belt length right! Way off the rails and there's still lots of looseness!

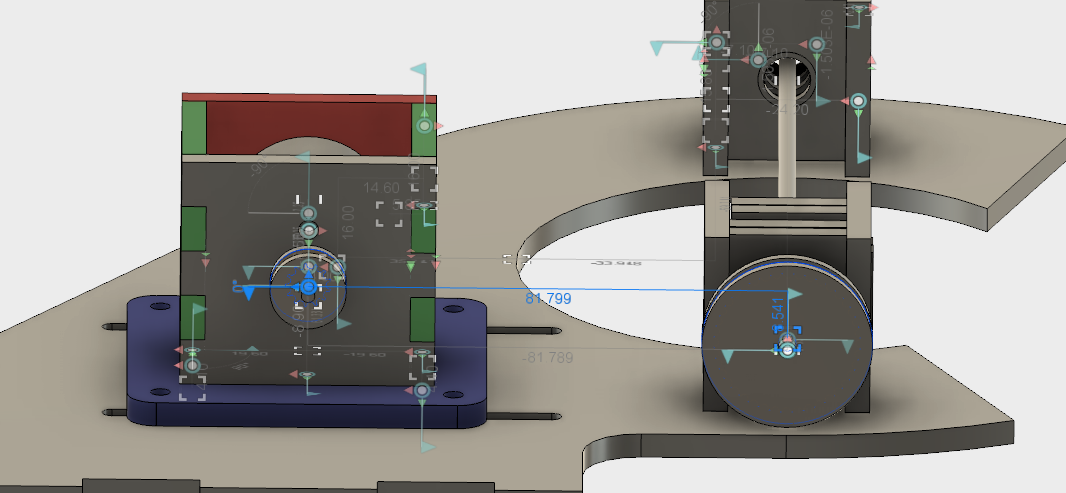

Turns out, I had it calculated for ~300mm on an older pulley design. But the old pulleys had to be reduced in size to clear the base plate:

New designs work out to be around 250mm, so I have a couple new belt sizes coming in that bracket that measurement. Bonus: I'm starting to build up a collection of sizes! The rapid prototypers' dream, the space-constrained apartment nightmare.

Jarrett

Jarrett

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.