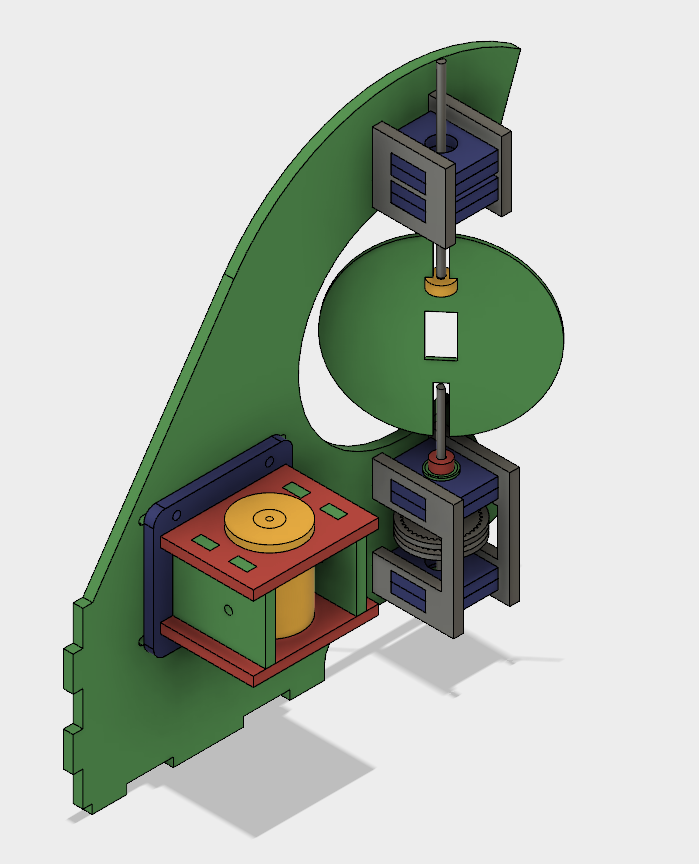

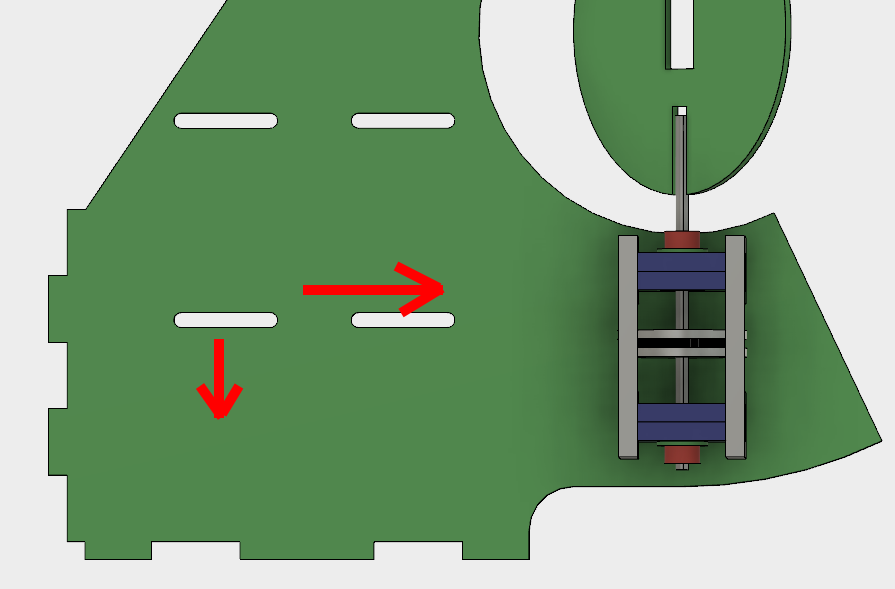

As mentioned earlier, some minor mechanical redesign was in order.

The driven pulley was moved to prevent cantilevering, and I switched to D-profile shaft to allow some extra laser-cut pieces to couple the PCB.

Cut it all out and assembly time.

Resulting in massive lossy GIFs:

I'm actually super stoked about the speed and how stable the whole thing is. Excuse the handheld shaky-cam.

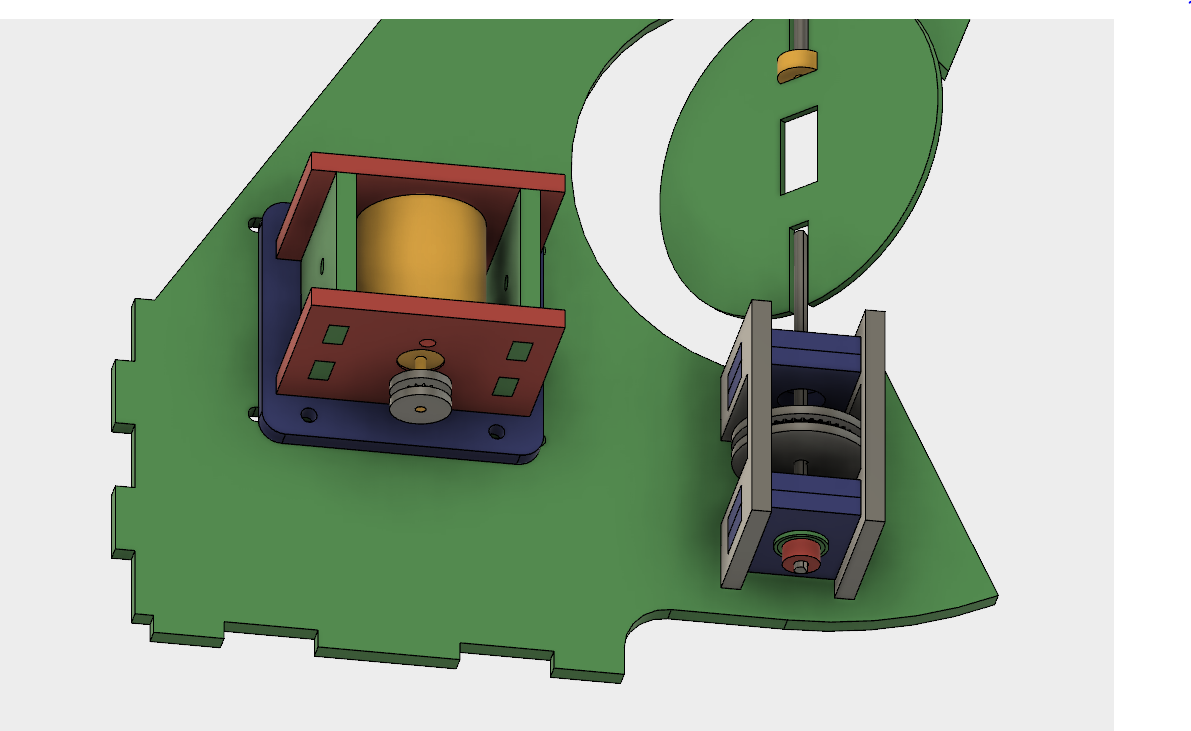

A couple minor issues:

The large pulley is still a little bit close to the upper bearing, it's either rubbing or in danger of rubbing. There's a ton of room below it, so what needs to be changed are the motor mounting slots. A little bit lower. Additionally, the belt is at full tension while the motor carriage all the way to the right. So it works, but it would be nice to have a little bit more clearance.

So, in summary:

Down 3mm, to the right 3mm.

Jarrett

Jarrett

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.