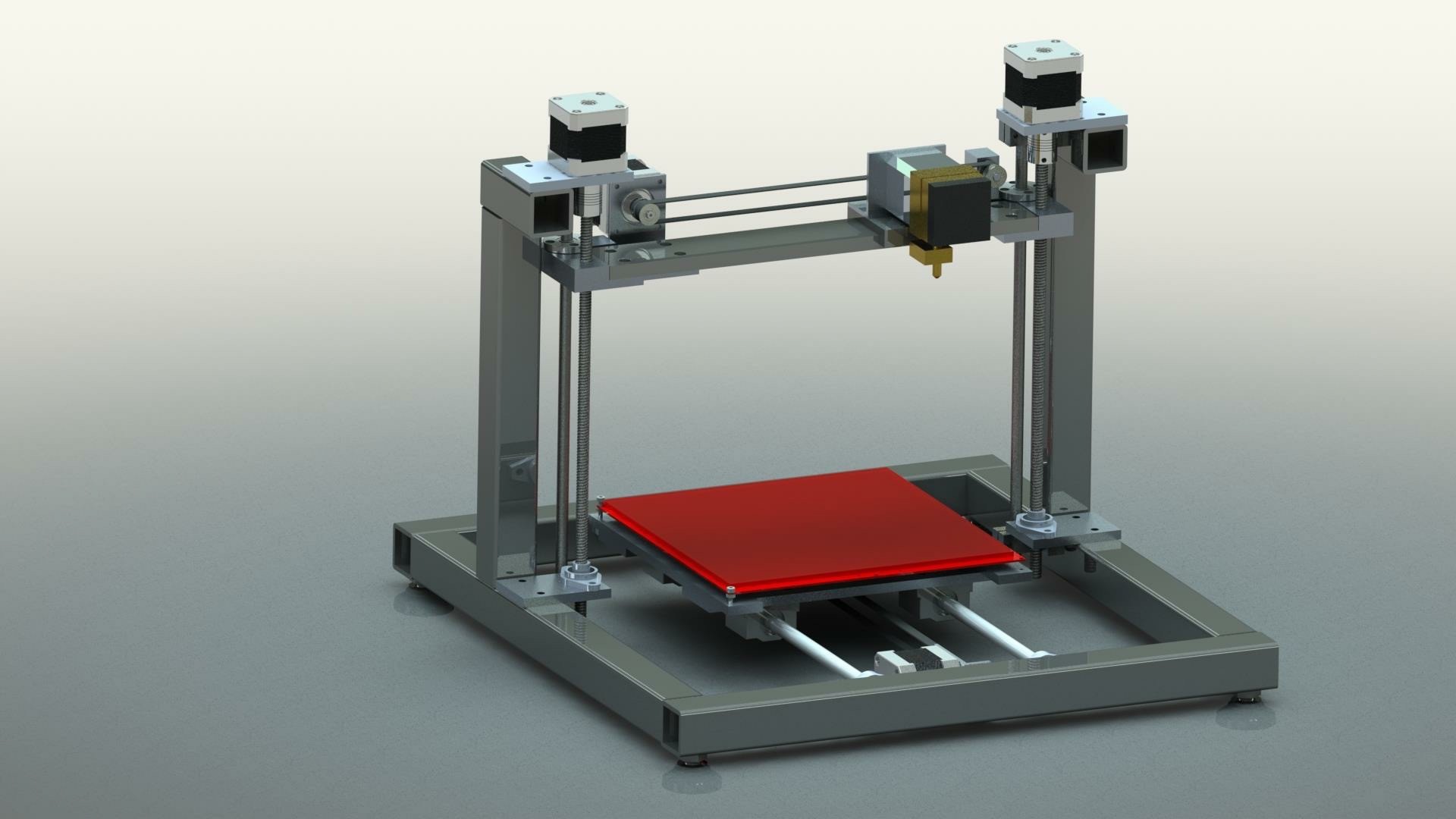

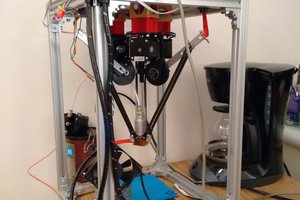

My first idea was to build a cheap 3D printer by my myself. In 2014, there were some 3D printers on the market, but it was too expensive. So I've decided to design and make my own 3D printer as a personal project during my mechanical engineering studies. I did the design according to cheap parts that I could find on eBay and with recycled aluminium and steel parts that I've got. The picture below is my original 3D model :

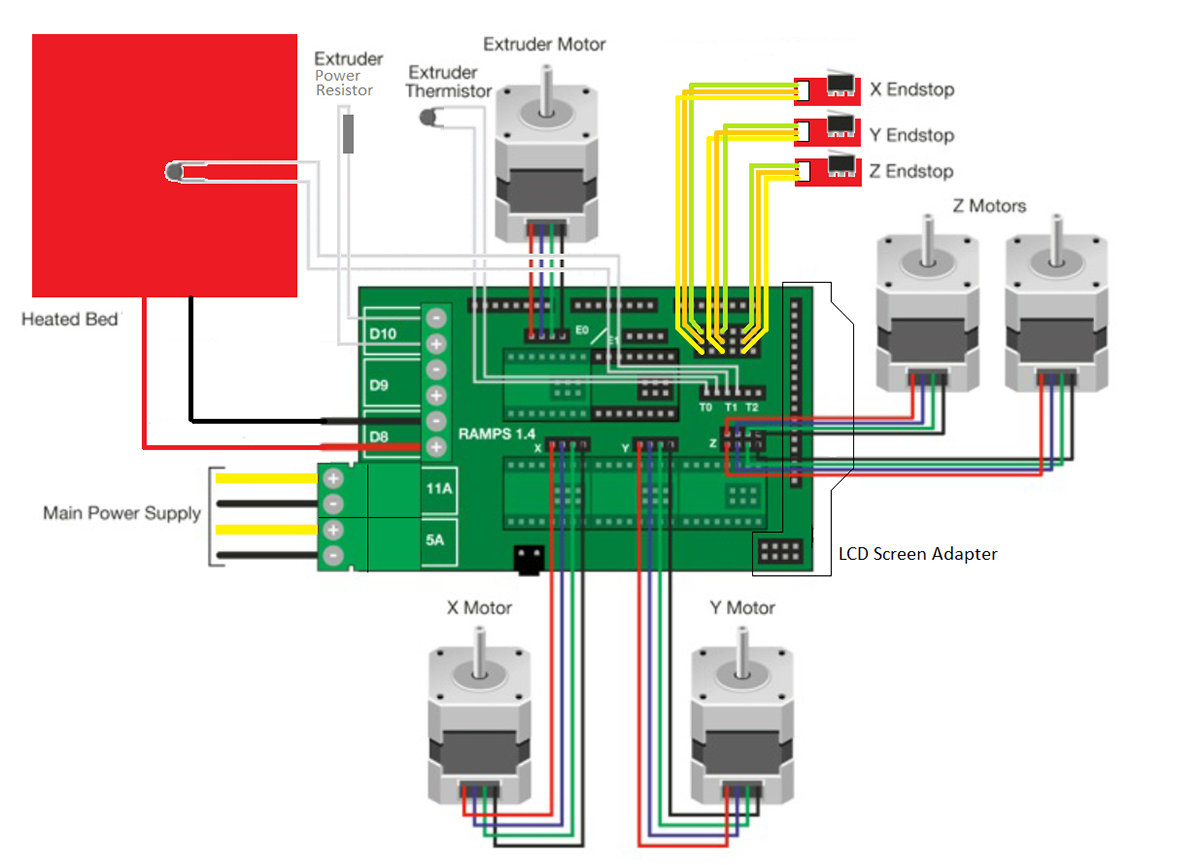

This is the wiring diagram of the Ramps 1.4 :

The firmware that I've used if Marlin : https://github.com/MarlinFirmware/Marlin

The following pictures are an example of a part that I designed and machined on a conventional milling machine. It is used as an holder for the Z axis.

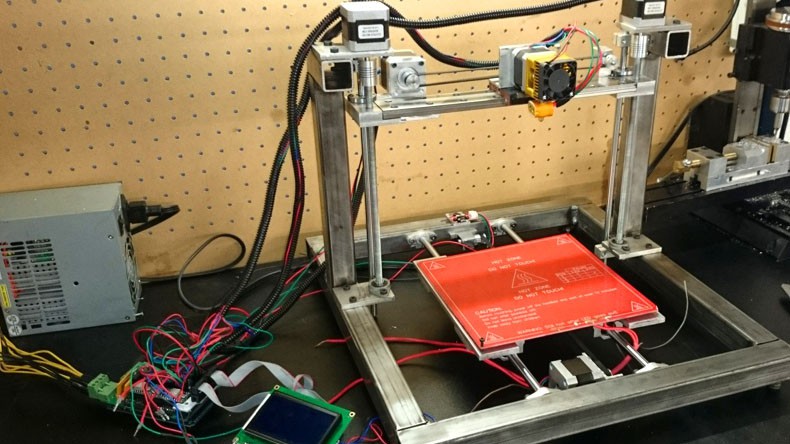

I used a PVC junction box for the electronic parts. The power supply is a recycled power supply for a computer (ATX power supply). The total price for this project is about $350 USD.

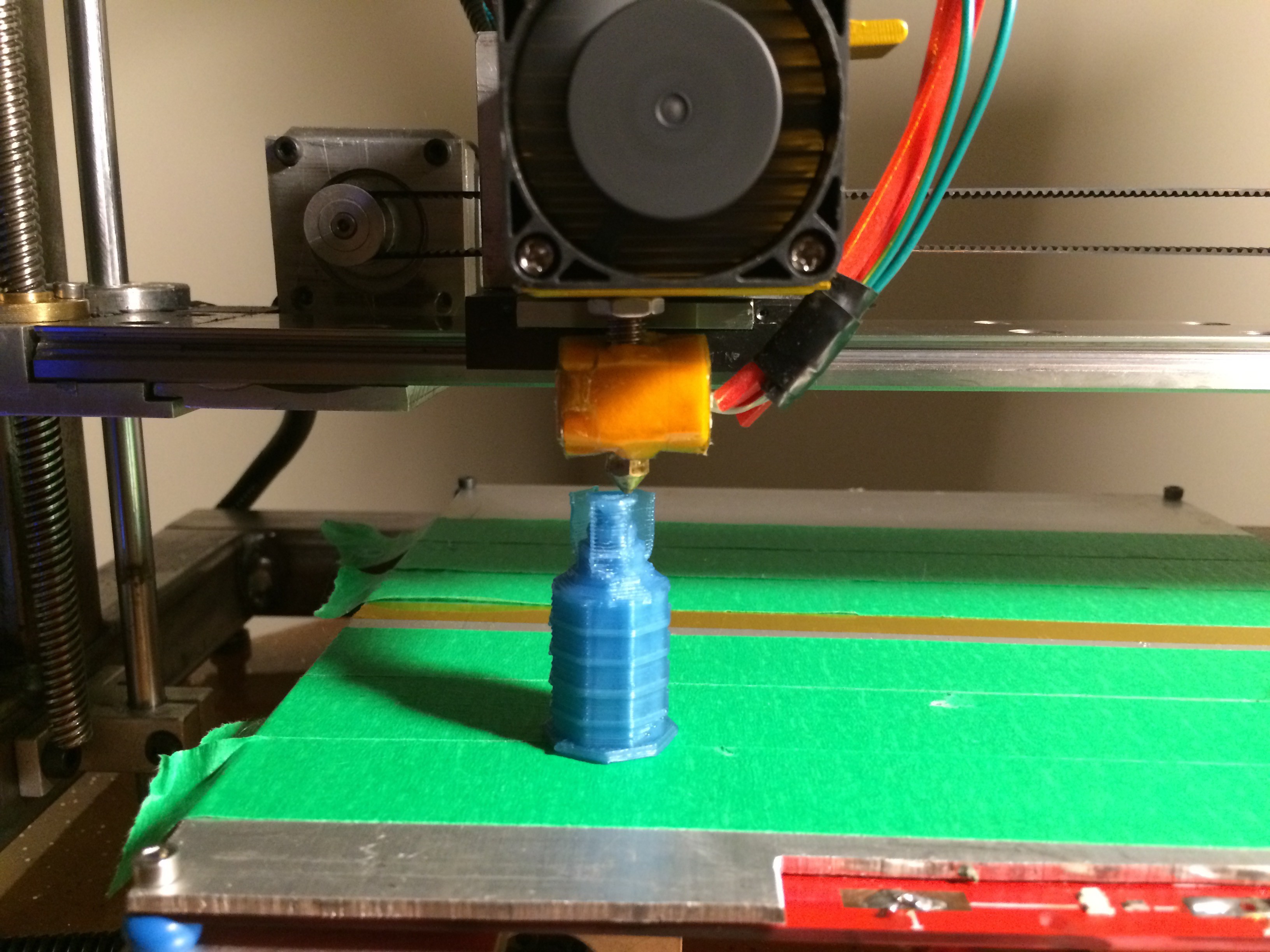

The picture below is one the first completed parts that I've printed... A Stanley cup.

The picture below is an example of a rapid tooling that I've made. This is a jig to drill holes with drill bushings.

Fred

Fred

Will Church

Will Church

Greg Zumwalt

Greg Zumwalt

TTN

TTN

loren

loren

Nice build! I really like square tubing, easy to work, looks good.