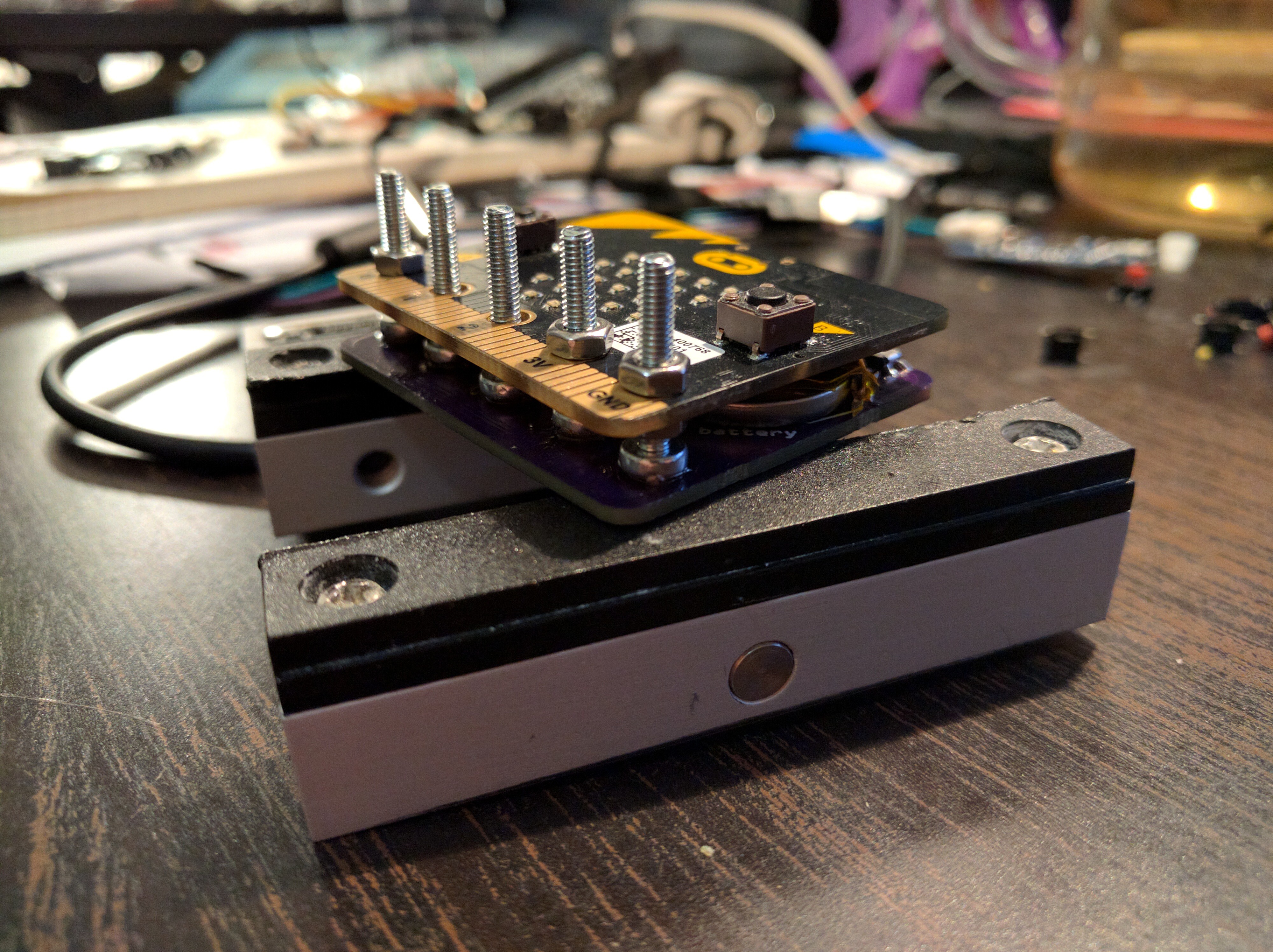

One of the main challenges when making an accessory for the micro:bit is connecting it to the device. The large holes might be convenient for alligator clips, but not for pretty much anything else, and the edge connector is huge and hard to design a PCB for. This time, since I only need two pins for I2C and one for the speaker, I decided to go with bolts. However, I don't have room on the front side of the board for bolt holes (the display and buttons are too wide), so I need them in a "surface mount" version. Turns out that some large pads with vias, together with solder paste and a generous application of the hot air gun work pretty well for that:

I even found some brass bolts without heads dedicated to be soldered to a PCB, but it will be a while before those arrive, so in the mean time I'm testing with regular bolts.

deʃhipu

deʃhipu

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.