N+ IS EVERY SHOE YOU NEED

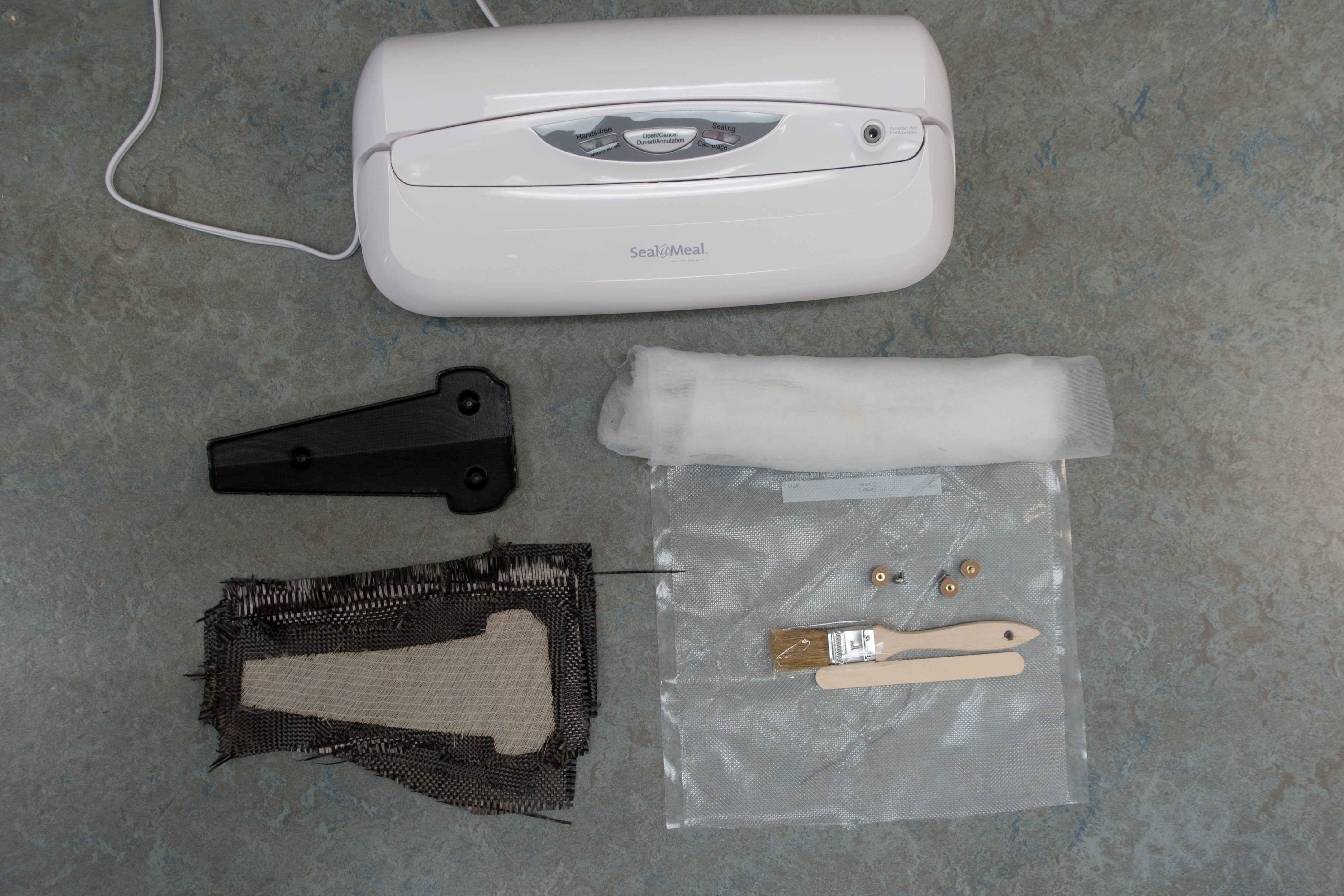

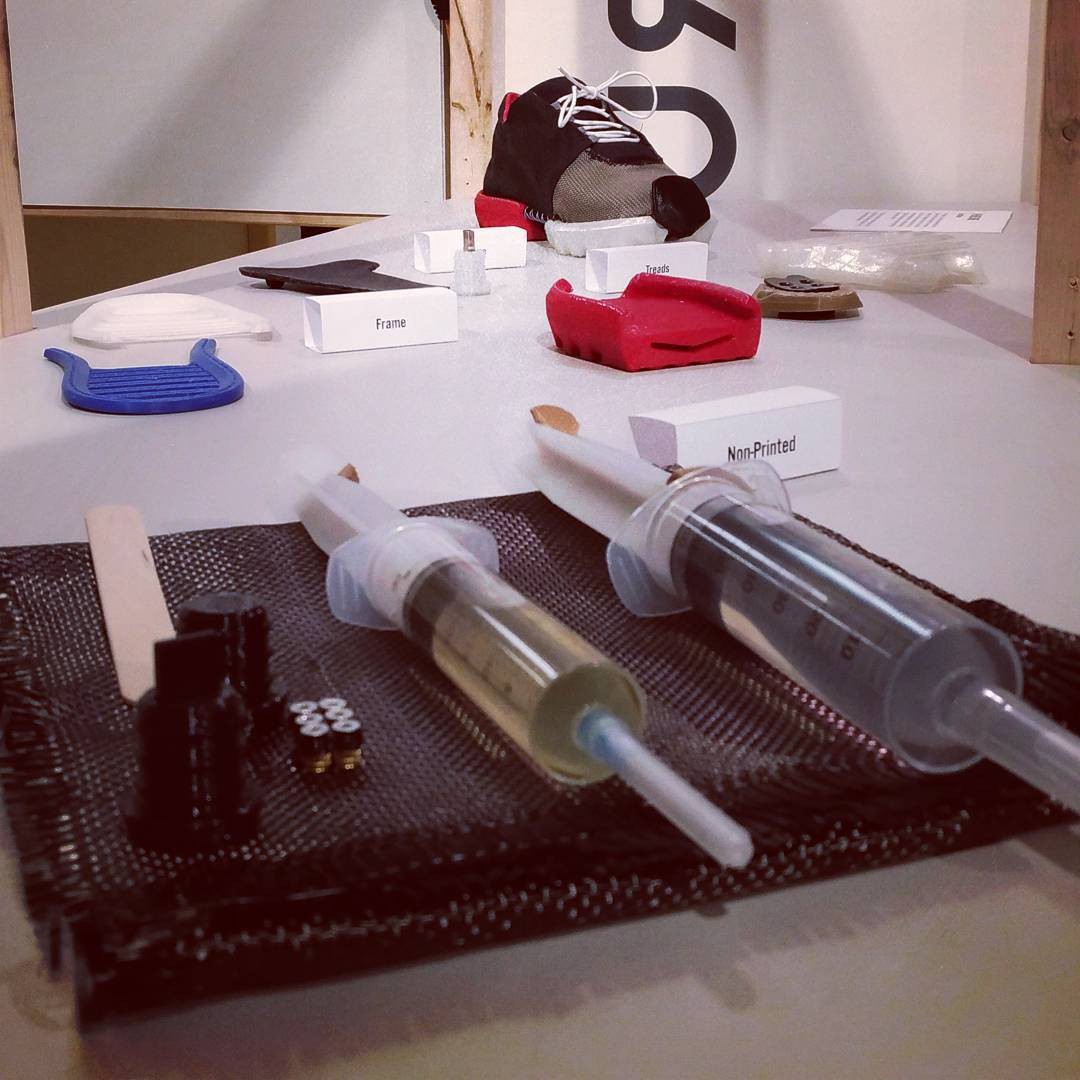

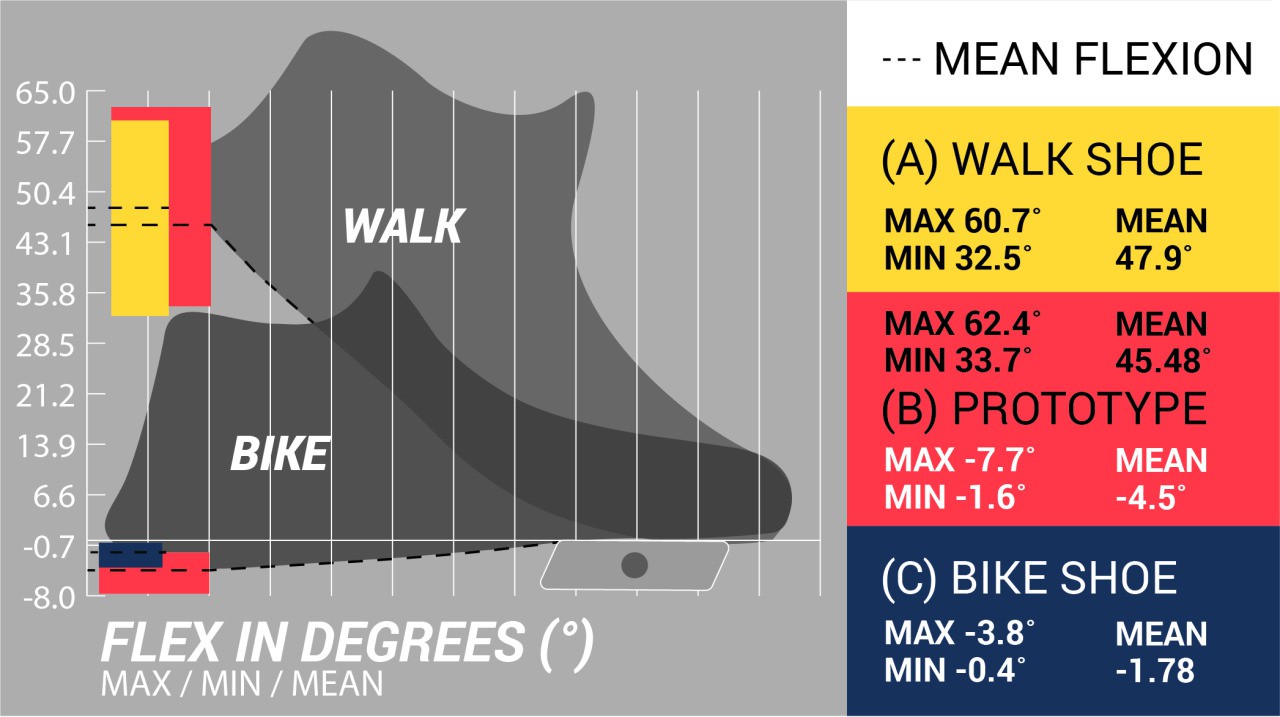

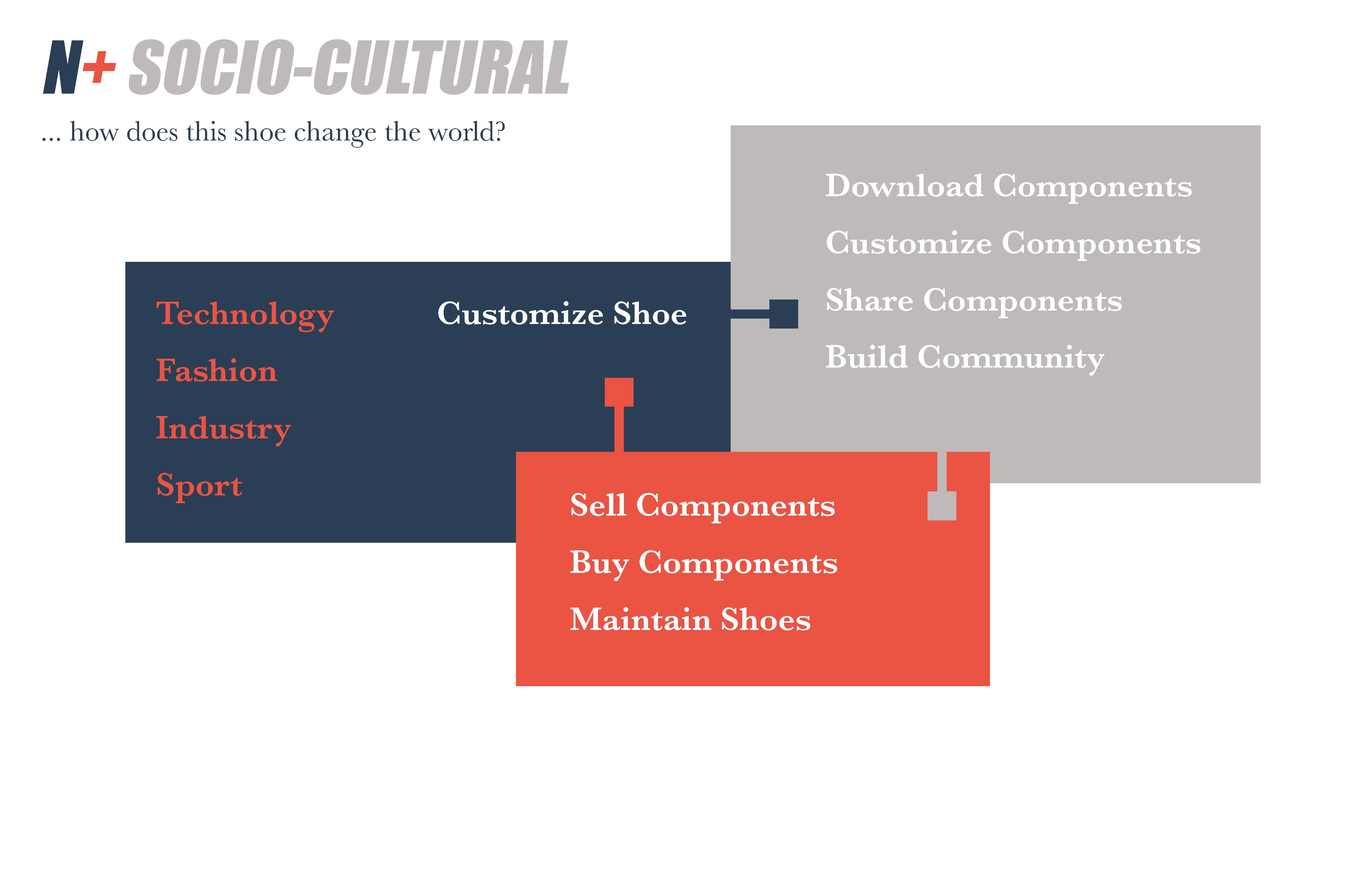

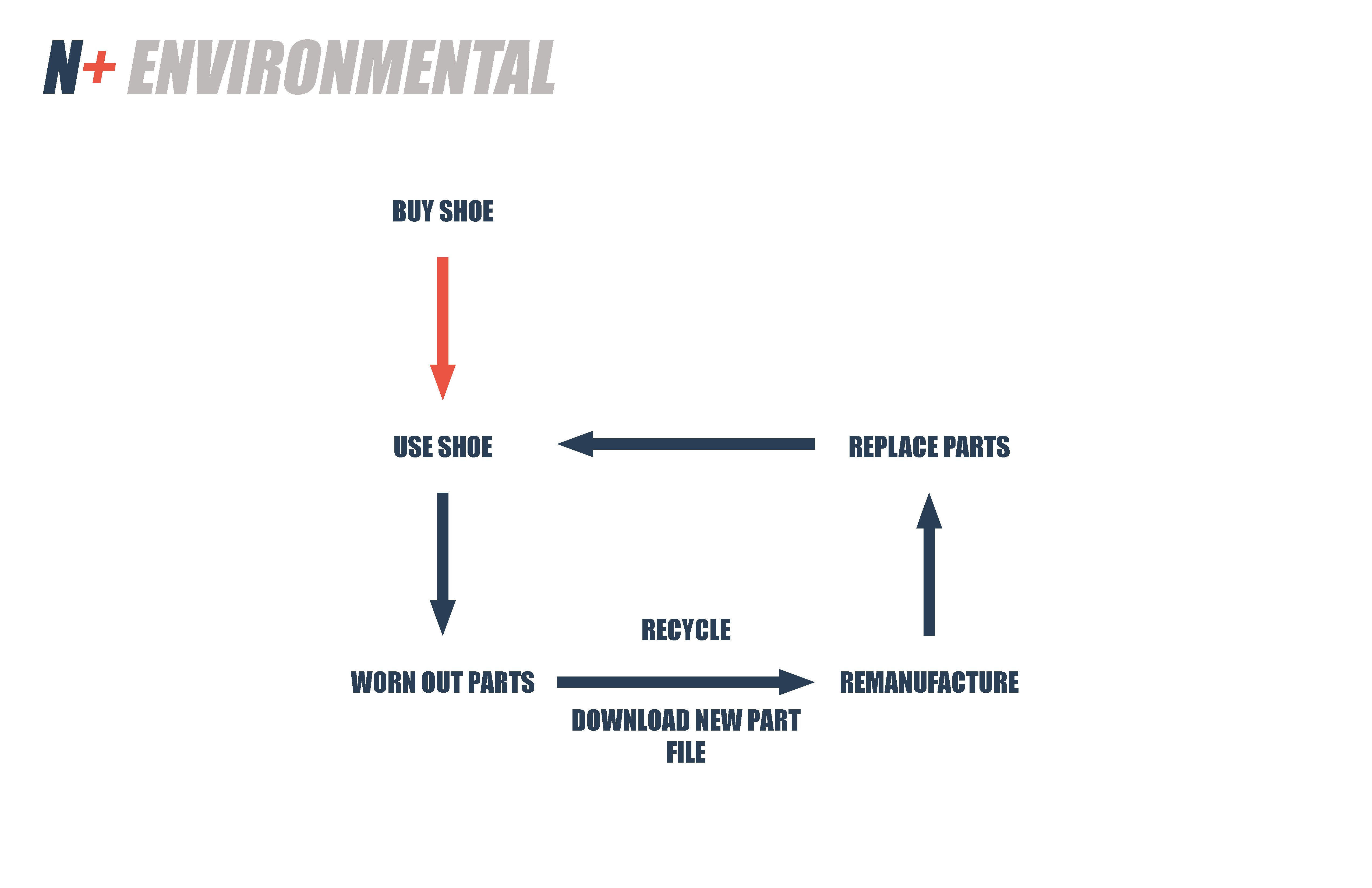

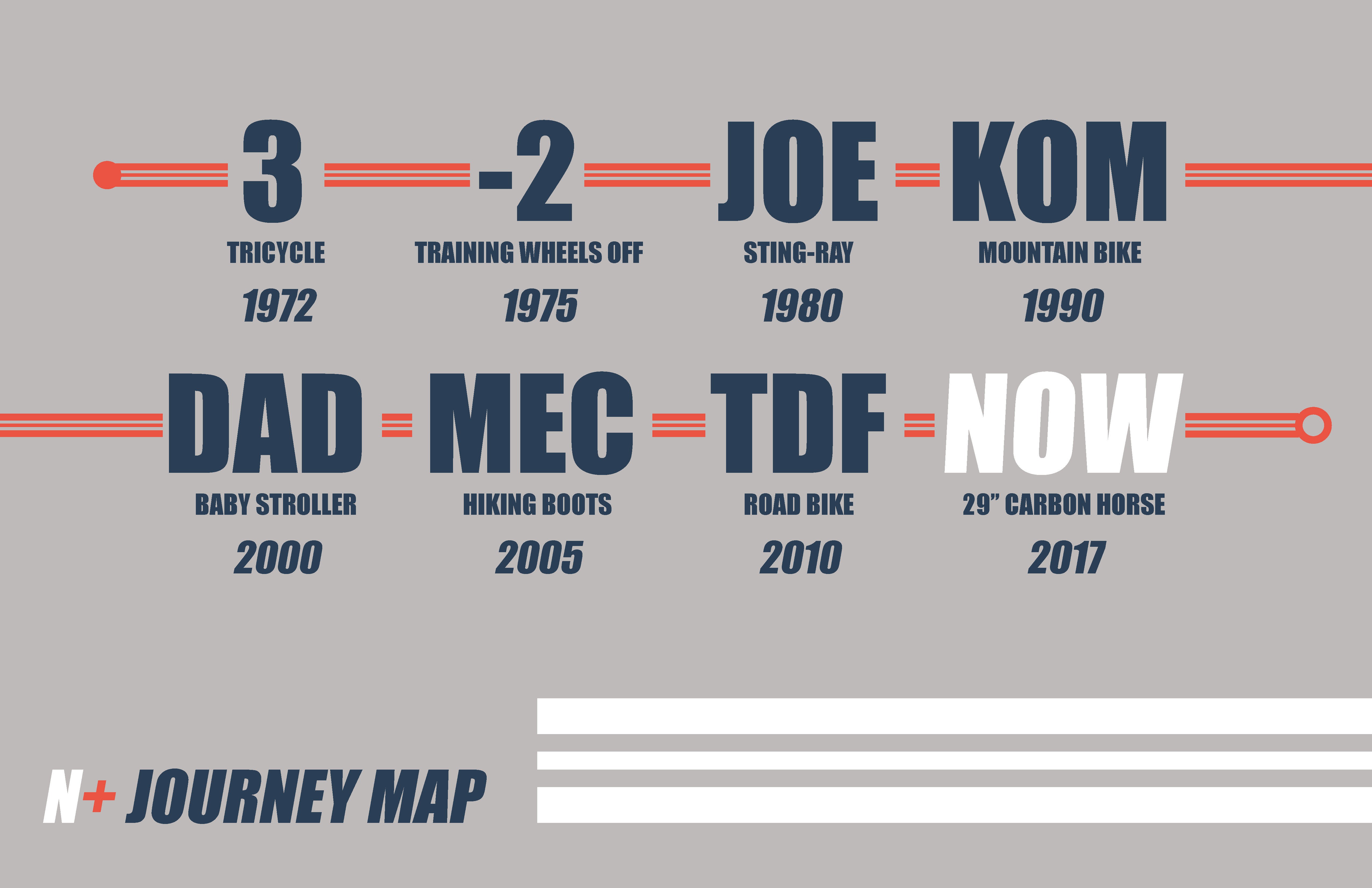

Cycling shoes cost a fortune, and serve a very specific fit and function. I wanted to make an alternative to consumer shoes that could be produced using a 3D printer, sewing machine and other readily available bits. The shoe was to be customizable - so that anyone could adjust it to fit their weird feet, or modify the treads to suit their next adventures terrain. The textile uppers of the shoe would have to be removable and come together without adhesives, to that they could be easily serviced and modified.

Because riders are often needing good shoes in different seasons, or conditions ranging from mud and snow, dirt and dust, or asphalt, the idea of an open shoe platform took shape. For now I've got a single simple upper and set of treads but I'm looking for collaborators who want to give it a shot and see where we can take it. Here's looking at YOU Adidas / Five.Ten FUTURECRAFT.

This shoe is in development. Now that the deadlines of the project are limitless I've been giving it lots of thought and little action. It will pick up again soon, so show some interest if you'd like to see more! Please gimme a follow on @marcsoriginal on instagram or twitter

THE HARD WAY

AT THIS MOMENT the parametric file is not easily shared, but anyone who wants to get plugged into the Fusion360 project and help to tidy it, please reach out.

See what I mean with the full file here

INSTAGRIZZ

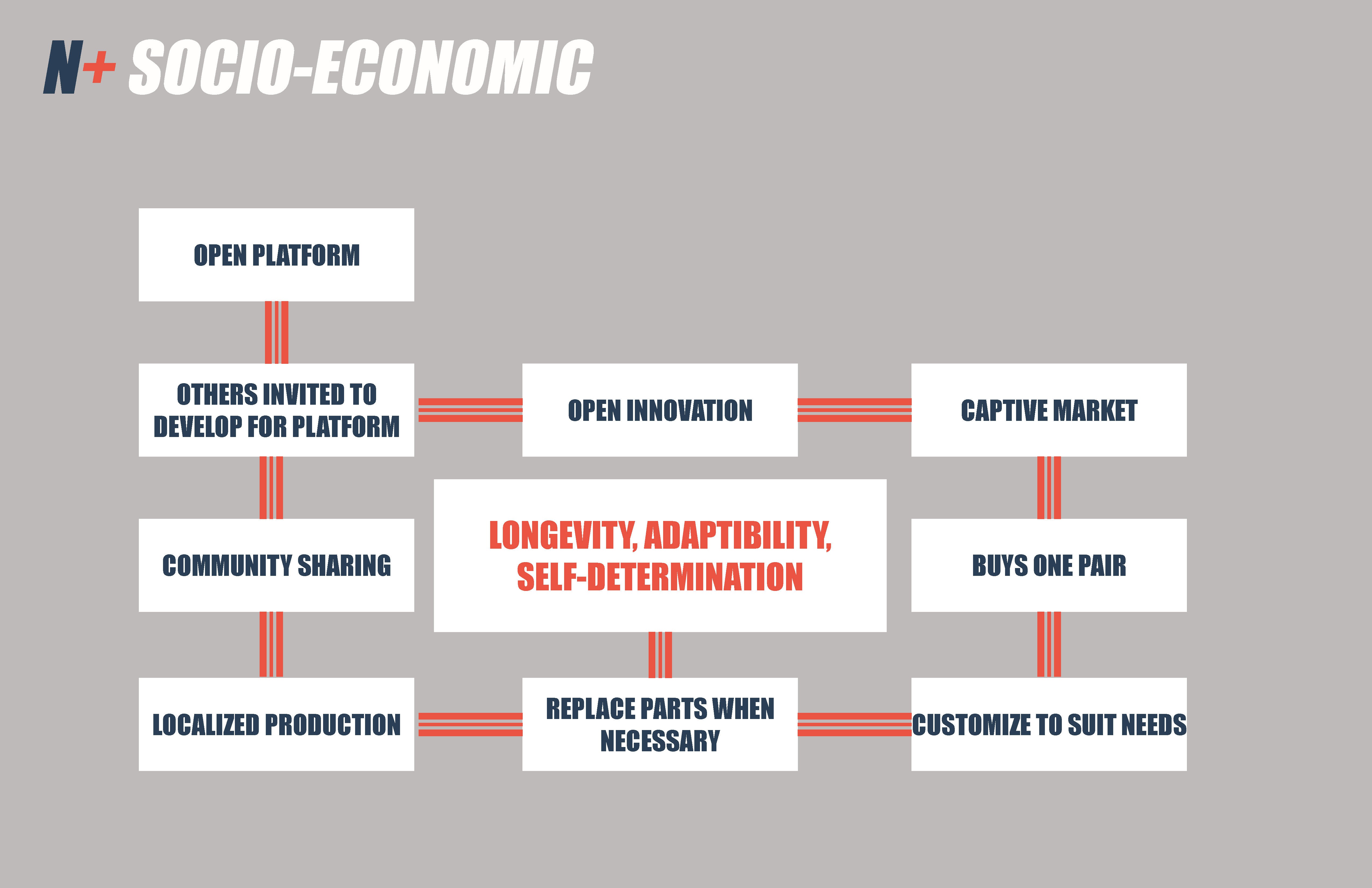

As an open source platform I imagine this project growing into something like Rep Rap or OpenRC, with potential to monetize it along the way. If some tire companies wanted to start casting rubber treads, that's coo. If some composite companies want to start producing carbon cores, that's coo. If apparel and footwear companies want to sell some standalone uppers suited to stitch onto the N+ platform, that IS COOL - I think of it like a new, unique tire size made the way you want it.

Thanks for looking!

marcs

marcs

colton.baldridge

colton.baldridge

Joan Horvath

Joan Horvath

Greg Stephens

Greg Stephens

TheMixedSignal

TheMixedSignal

This is really fantastic. How many other cyclists are there here? I'm now taking a shoe-making course to help me brush up on my drafting and design, leatherworking, and other abilities. I truly appreciate this idea you have here. For more information, you can check here. https://golfgenz.com/