Look at the 16 file image sequence below, they are all commented.

Just orient the red and black poles to your preference when assembling, they are easy to switch around.

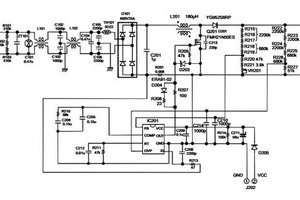

Theory of operation ,EAGLECAD Files and LTspice schematic simulation :

https://drive.google.com/open?id=0BxARZnl2qhssM3Fxd3RFNFB4S2c

Feature by Feature functional delivery technique & EAGLECAD Files

1) Rev polarity protection s handled by a PFET Drain to Source conduction for minimal voltage drop.

2) Transient suppression is done by a 16V TVS with a 5A fuse for extreme transients

3) Power shutdown for surge current, continuous excess current and power dip under load is controlled by a biased op amp using an LED for a voltage ref. and the Rdson of the output PFET for current sensing.

4) Thermal shutdown is triggered by the positive tempco of the Rdson of the PFET.

5) Noise suppression is done by a pair of 10nF ceramic caps with high voltage ratings to prevent capacitance degradation

6) Decoupling is via a larger 4.7 uF ceramic cap to reduce ripple and mitigate wring inductance.

7) Transient current draw support is enabled by slowing the gate response of the final PFET, but not so much as to compromise the fast shutdown upon over current.

Installation is simple as the circuit is inserted into the positive pole line to the plug and grounded via the existing FT817 power pole adapter ground screw.

Note that at full TX load the conditioner's MOSFETs will be too hot touch as they unload the FT817 of 10% of heat dissipation making for longer transceiver life. So, don't burn your fingers. Ensure proper ventilation for the conditioner when transmitting.

mosaicmerc

mosaicmerc

Adharsh K

Adharsh K

Bud Bennett

Bud Bennett

engineerkid1

engineerkid1

I ordered a PCB on eBay. Unfortunately it does not work. It always burns the red LED.