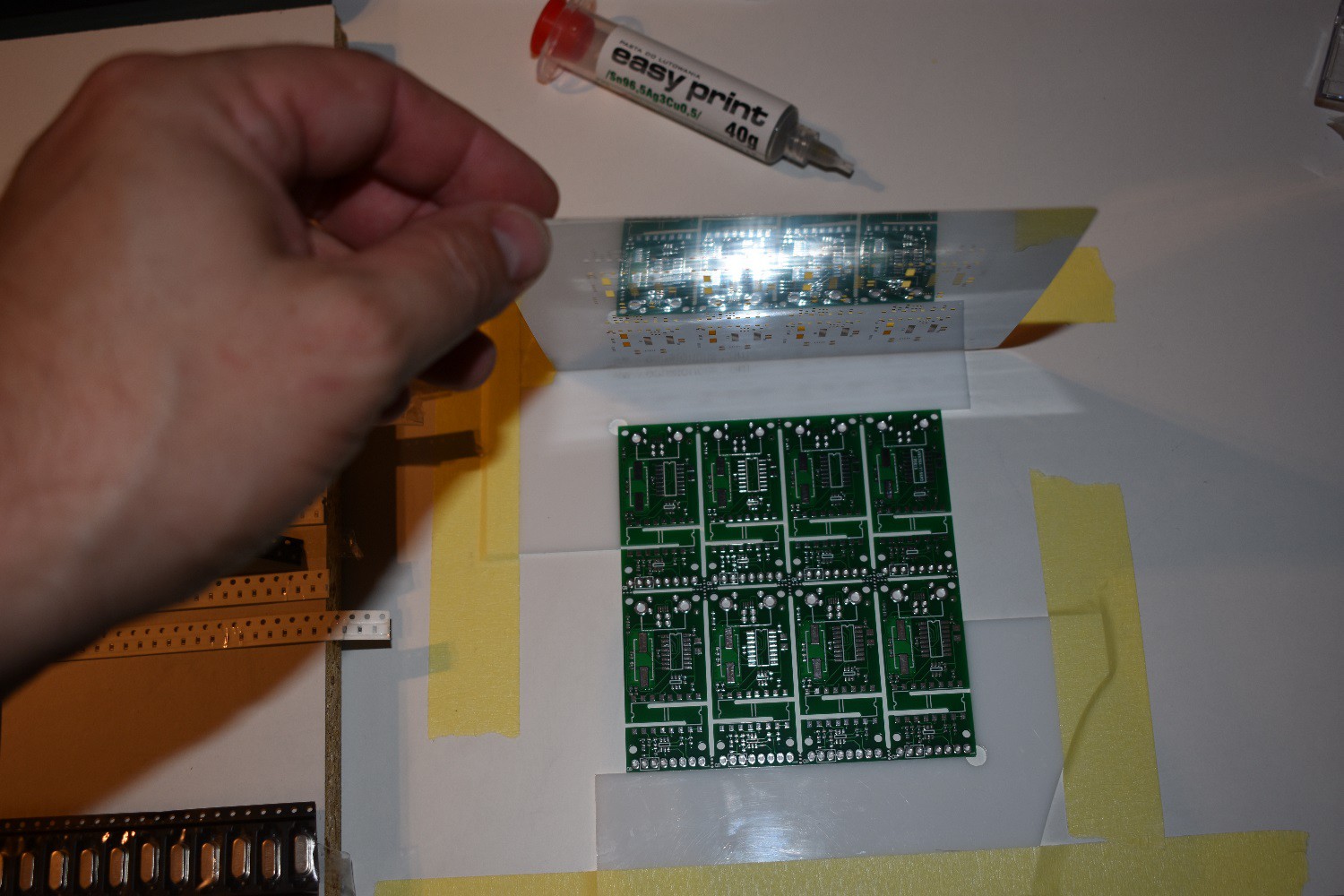

The solder paste is applied using a stainless stencil from oshstencils.com. These stencils are very nice and easier to use than plastic stencils. Result in next picture.

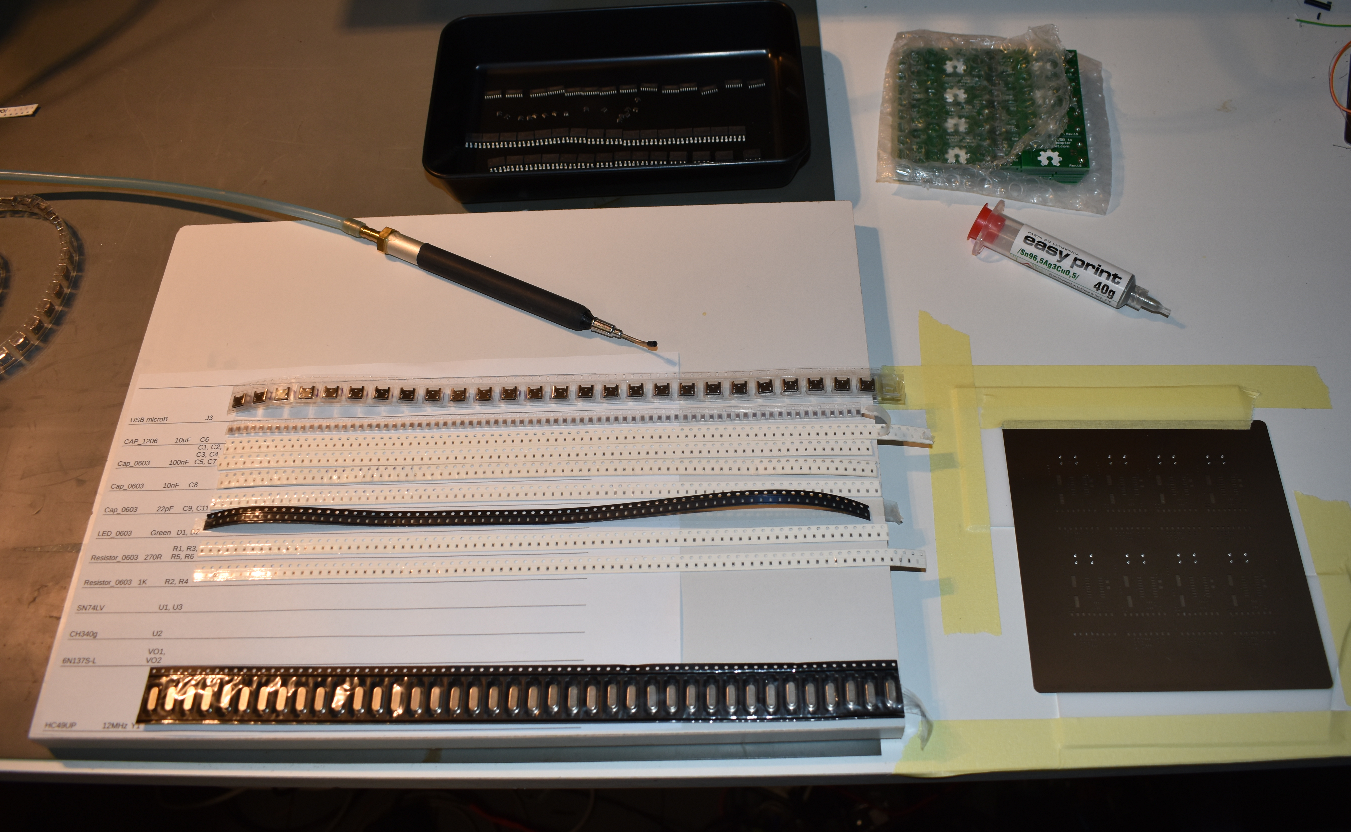

All the parts layed out. I use a home made vacuum pickup tool to place the parts. It uses exactly the same vacuum system as my never ending PNP machine project.

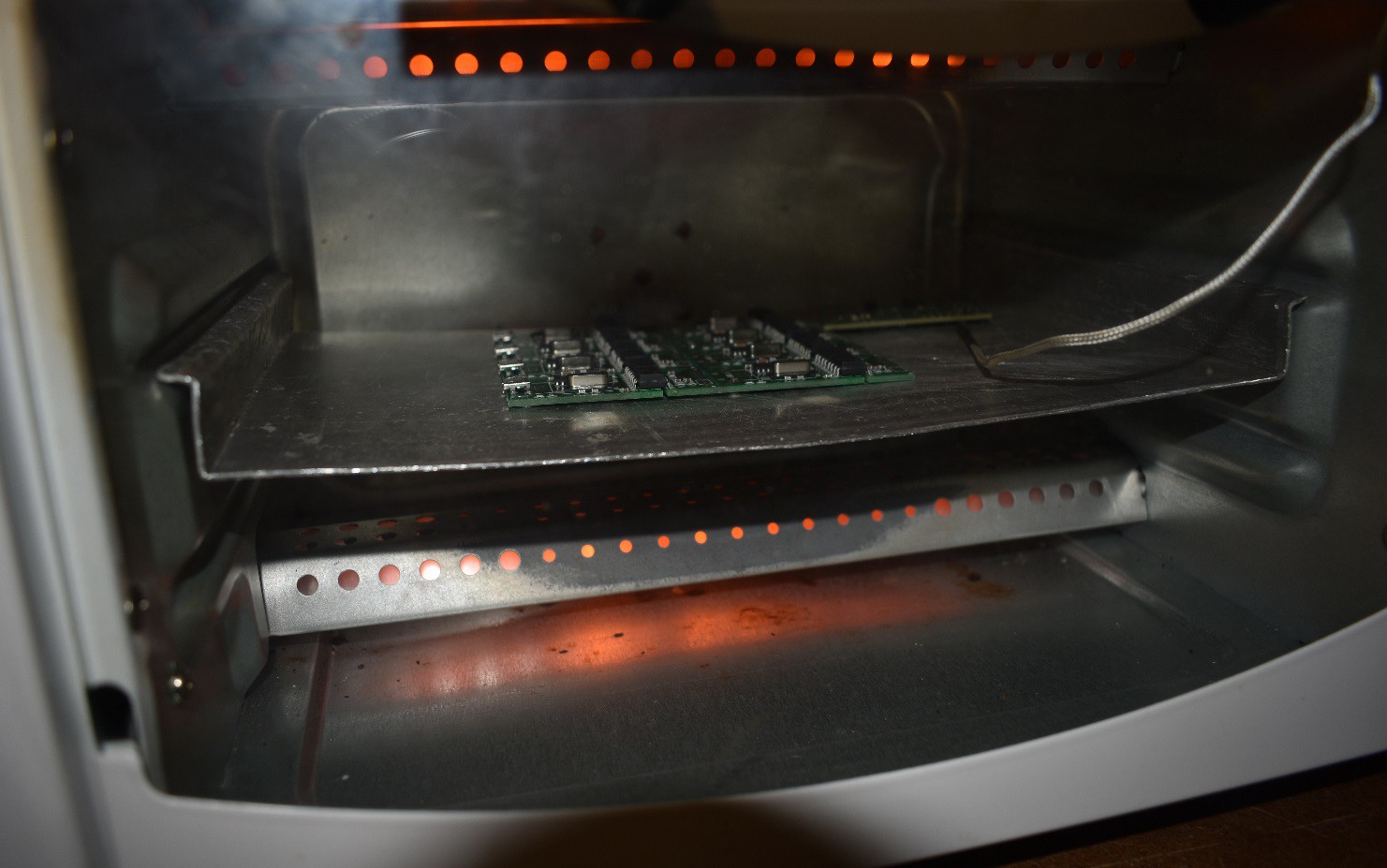

Reflowing in my converted toaster oven. As you can see in the picture the IR heaters are on, but it uses mostly convective heating. The IR is only on ~20% of the time during a typical reflow. (BTW, the gray fuzzzy thing in the top left corner is not smoke, it's light reflecting of the glass door.)

ZeptoBit

ZeptoBit

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.