Things You Need

Hardware Components:

- DFRduino UNO R3

- DFRobot I/O Expansion Shield

- DF05BB Tilt/Pan Kit(5Kg)

- DFRobot Photocell x 4

- Resistor 10kOhm x 4

- DFRobot Solar Panel

Software:

- Arduino IDE

Tools:

- Solder Iron

In modern solar tracking systems, the solar panels are fixed on a structure that moves according to the position of the sun.

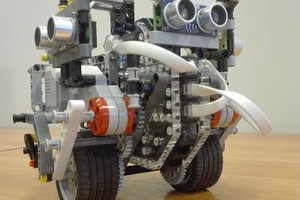

Let us design a solar tracker using two servo motors, a light sensor consisting of four mini photocells and Arduino UNO board.

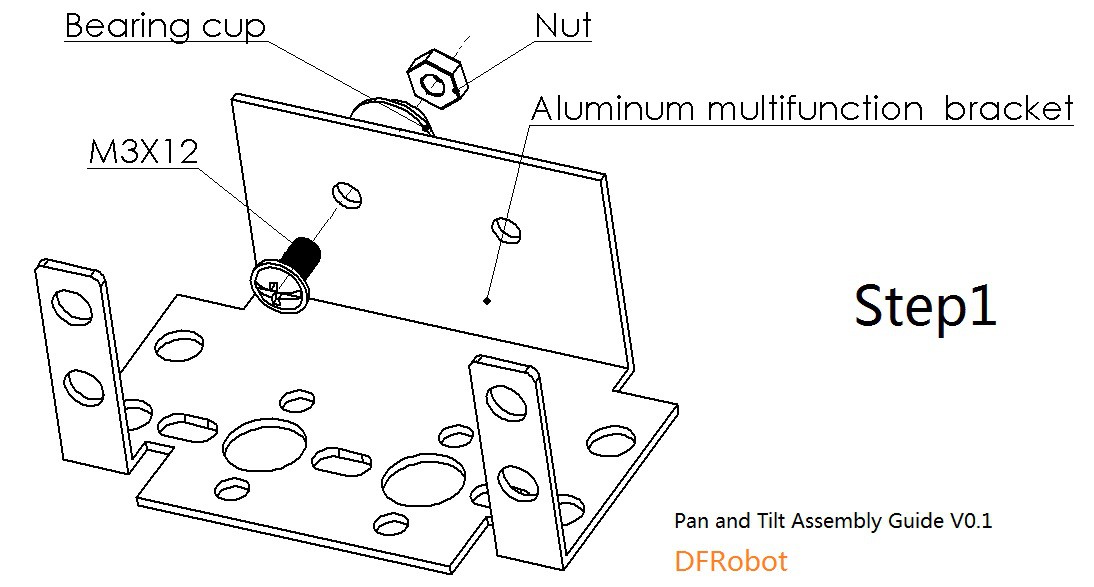

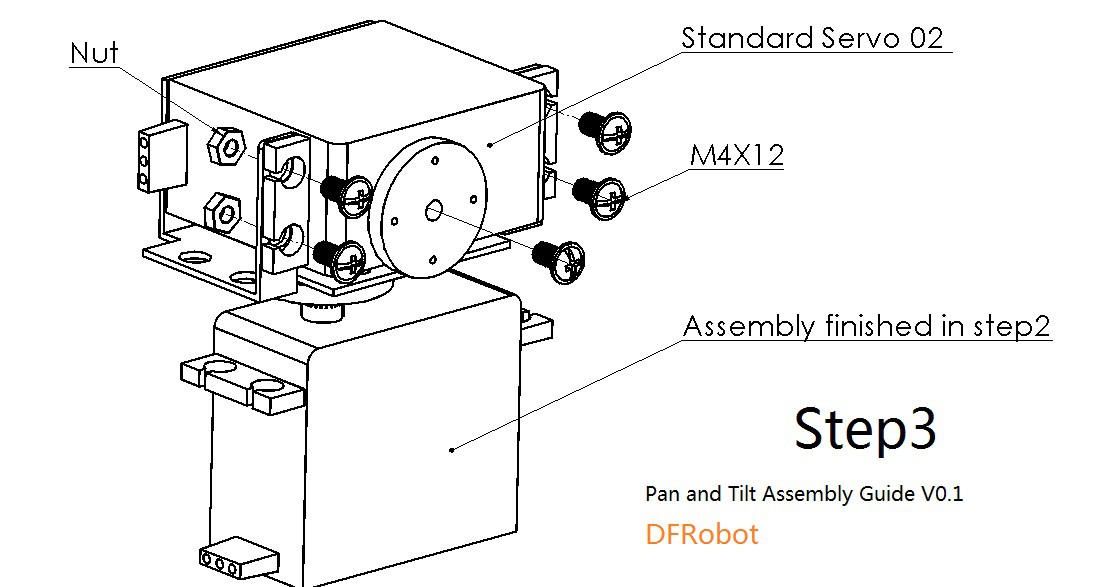

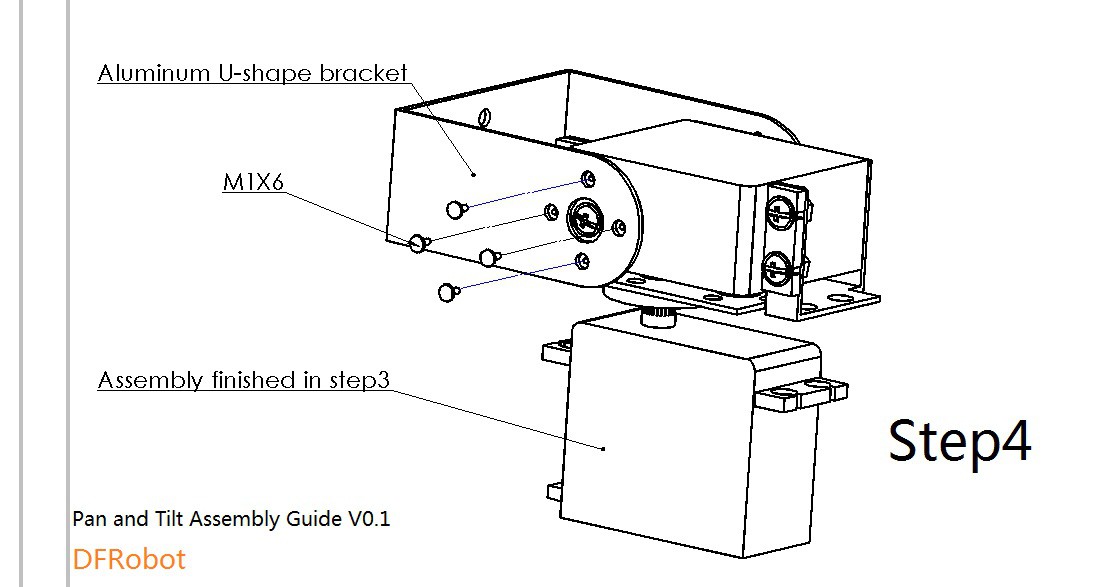

Assembly of the Pan Tilt

Follow the steps in the images above and assemble the parts.

Remember: Use rubber spacers when using the M1x6.

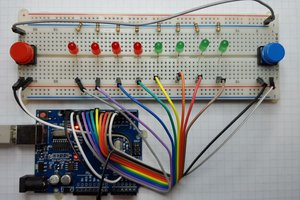

Connections

Stack the I/O Expansion Shield on the Arduino.

- Connect lower servo with D9 in shield.

- Connect upper servo with D10 in shield.

- Take +5V and GND to power rails in breadboard.

- Connect +5V in breadboard to each photocell.

- Connect upper left photocell to A0.

- Connect upper right photocell to A1.

- Connect lower right photocell to A2.

- Connect lower left photocell to A3.

- Connect GND terminal of each photocell to GND with 10k Ohm resistor in series.

Fixing and Testing

- Fix the Solar Panel on a cardboard and paste it on the face of upper servo.

- Take out all the wires and give them a play so as to move about 180 degrees.

- Put the system on a stable platform.

- Upload the code and test it with a bright LED or a bulb.

Schematics

Image source : Electronics Hub![]()

CODE

#include<Servo.h>

Servo servohori;

int servoh = 0;

int servohlimithigh = 180;

int servohlimitlow = 0;

Servo servoverti;

int servov = 0;

int servovlimithigh = 180;

int servovlimitlow = 0;

//Assigning LDRs variables

int ldrtopl = 0;

int ldrtopr = 1;

int ldrbotr = 2;

int ldrbotl = 3;

void setup() {

servohori.attach(10);

servohori.write(0);

servoverti.attach(9);

servoverti.write(0);

}

void loop() {

/* code */

servoh = servohori.read();

servov = servoverti.read();

//capturing analog values of each LDR

int topl = analogRead(ldrtopl);

int topr = analogRead(ldrtopr);

int botl = analogRead(ldrbotl);

int botr = analogRead(ldrbotr);

// calculating average

int avgtop = (topl + topr) / 2; //average of top LDRs

int avgbot = (botl + botr) / 2; //average of bottom LDRs

int avgleft = (topl + botl) / 2; //average of left LDRs

int avgright = (topr + botr) / 2; //average of right LDRs

if (avgtop < avgbot)

{

servoverti.write(servov +1);

if (servov > servovLimitHigh)

{

servov = servovLimitHigh;

}

delay(10);

}

else if (avgbot < avgtop)

{

servoverti.write(servov -1);

if (servov < servovLimitLow)

{

servov = servovLimitLow;

}

delay(10);

}

else

{

servoverti.write(servov);

}

if (avgleft > avgright)

{

servohori.write(servoh +1);

if (servoh > servohLimitHigh)

{

servoh = servohLimitHigh;

}

delay(10);

}

else if (avgright > avgleft)

{

servohori.write(servoh -1);

if (servoh < servohLimitLow)

{

servoh = servohLimitLow;

}

delay(10);

}

else

{

servohori.write(servoh);

}

delay(50)

}

Hari Wiguna

Hari Wiguna

spark buzzer

spark buzzer

Have you referenced any case studies on trackers vs. stationary systems such as with https://www.allearthrenewables.com/blog/dealers/pv-tracker-vs-pv-fixed-mount-system ? I wonder if there are comparable metrics you could try to construct for your design relative to a stationary unit (?).