Ponoko Laser Cutting Service: Front Panel Tests.

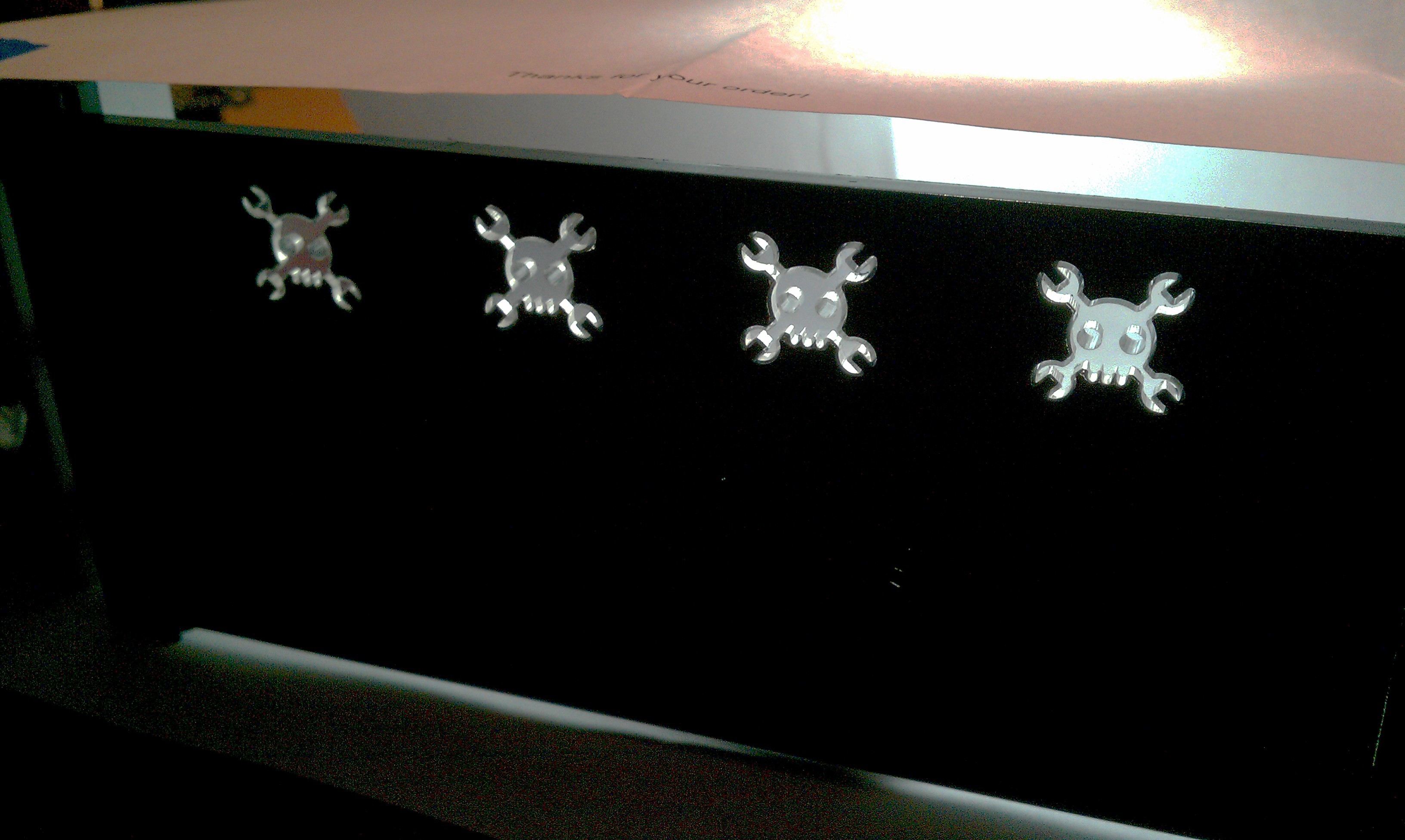

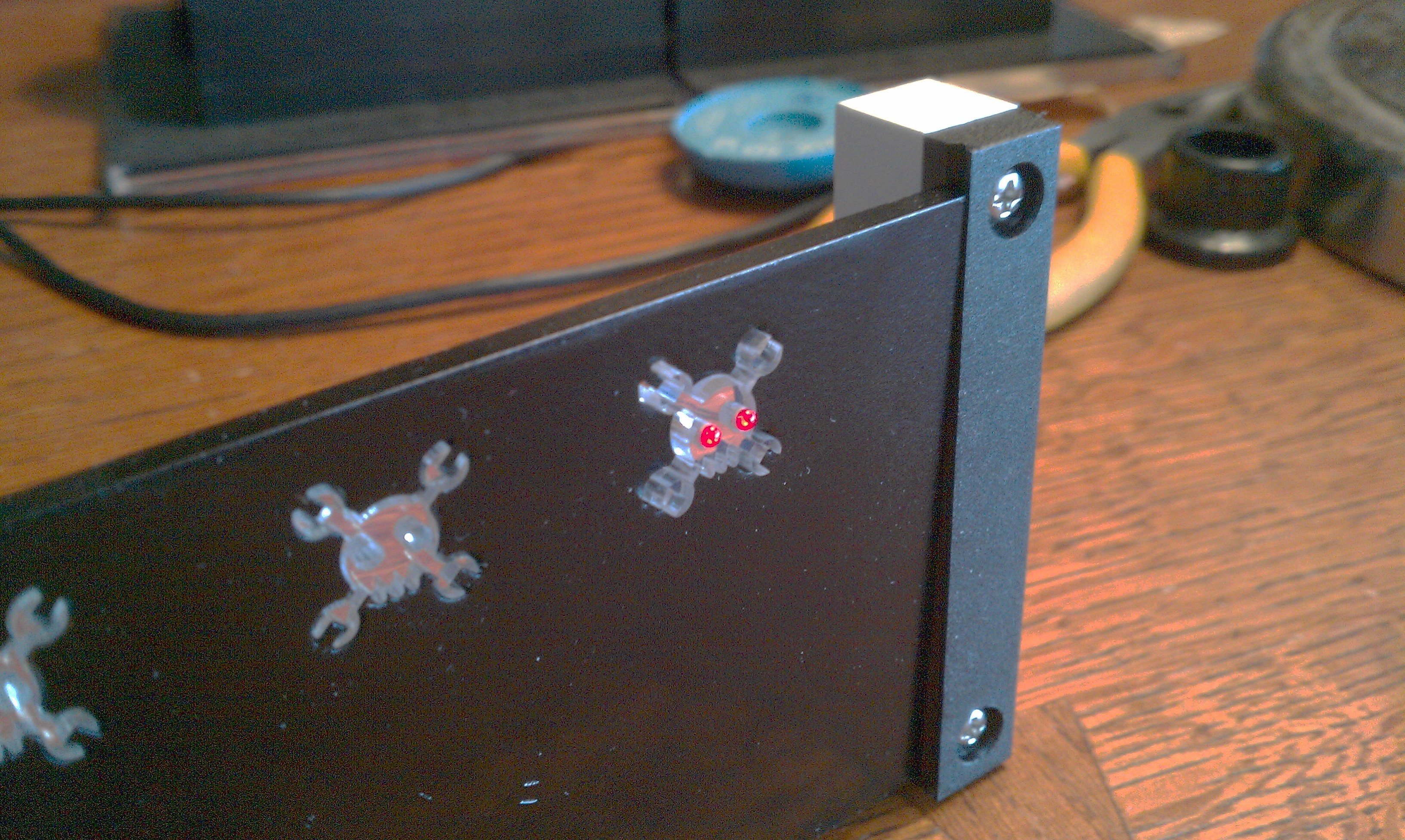

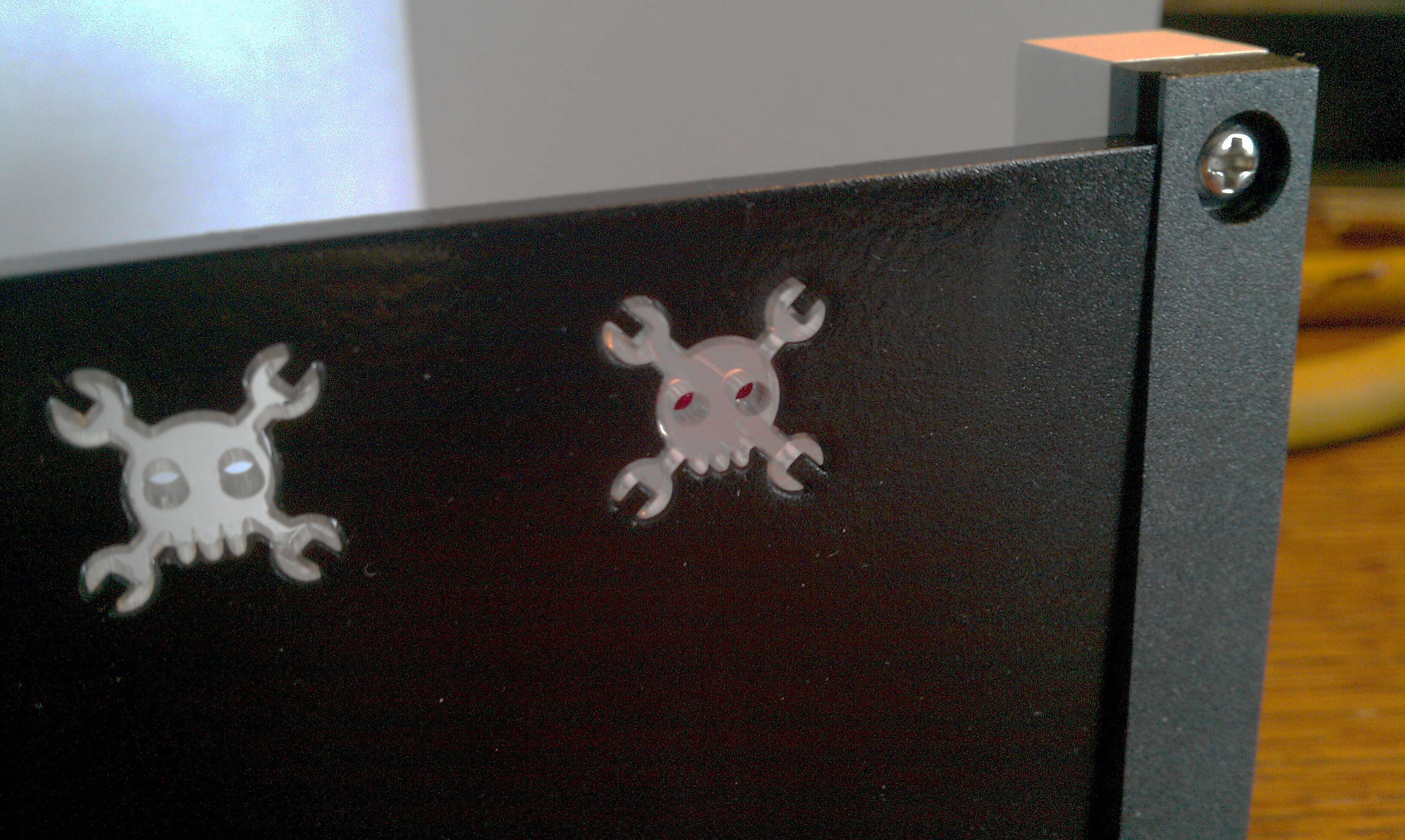

3mm clear acrylic skull inlays in black (painted) acrylic, with two 2mm red LED eyes. The red LEDs are not connected yet, but look like tiny jewel domes in the light. There are some more pictures below.

The inlays can be done in a variety of Ponoko's material combinations. I would like to play with inlays in wood, or in felt for clothes, but those are different projects.

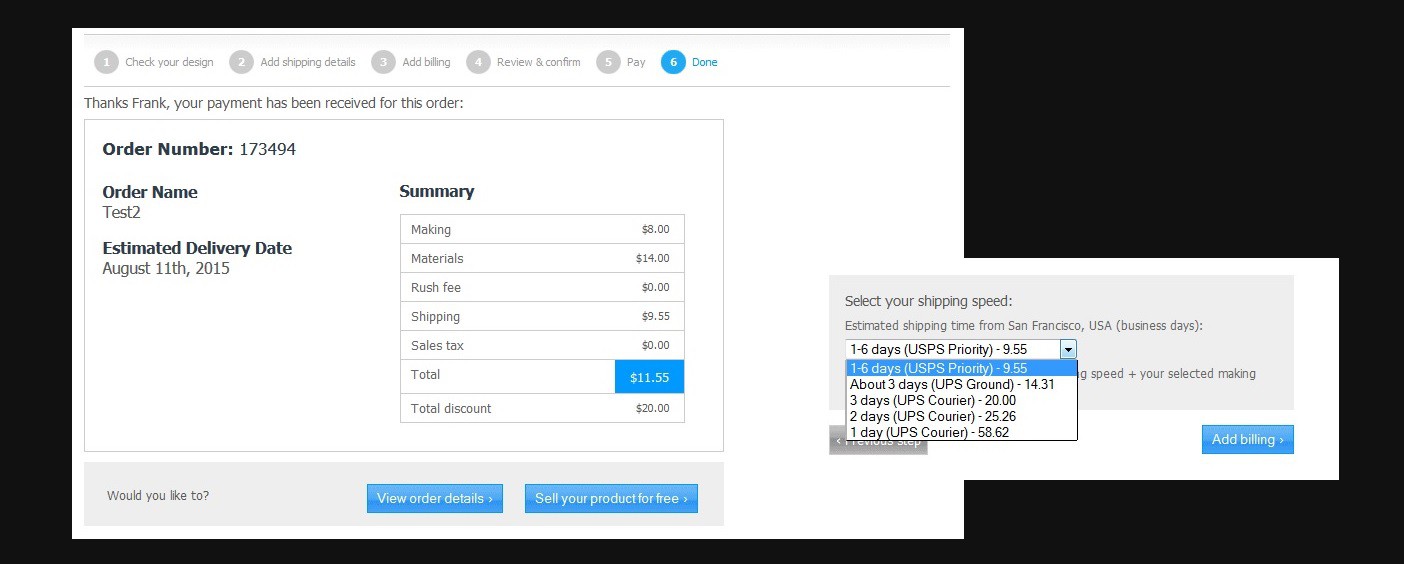

“Make Your First Product for Free”

I totally fell for the 'sign up now' because I was thinking I would eventually need to for the coupon I won.

The Catch:

Anyone can sign up for an account, and to find out there are 10 days left to use a $20US discount towards a laser cutting service only, not including shipping.

That actually was not a bad deal for me. I have never ordered any cutting or 3D printing before, so I knew for sure I would make a mistake on my first design. Not wanting to mess up a $100 order, I decided to play along and jump through the hoops. I thought the OpenSCAD Skull from the Human Interface log would be easy to send off. That might have been easier if it was 3D printed, but the preferred method of this laser cutting service is colored SVG files.

Ponoko has some great instructions for first time users.

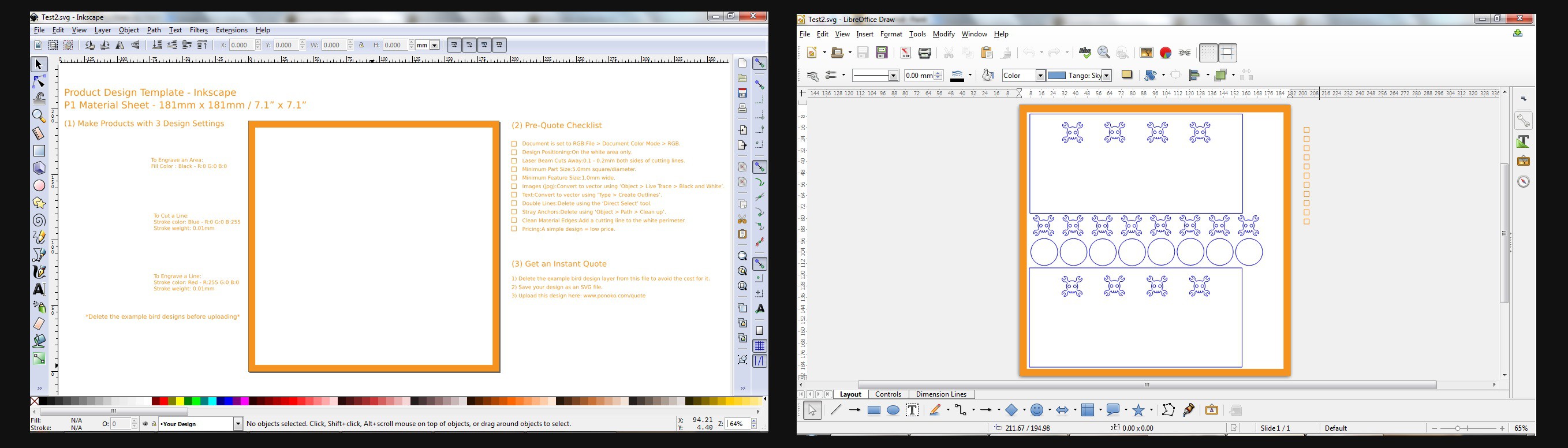

Following the design-it-yourself starter kits has to be fool proof, right? Fearing my LibreOffice Draw would be too quirky, I opted for the free Inkscape option so I could follow the directions. The good news is I learned some Inkscape in a few days. It's important to understand how lines connect with nodes, and how to watch for tricky connections and overlapping lines. The Ponoko directions in the starter kits are great, but now that I understand SVG files better, I will only be using LibreOffice.

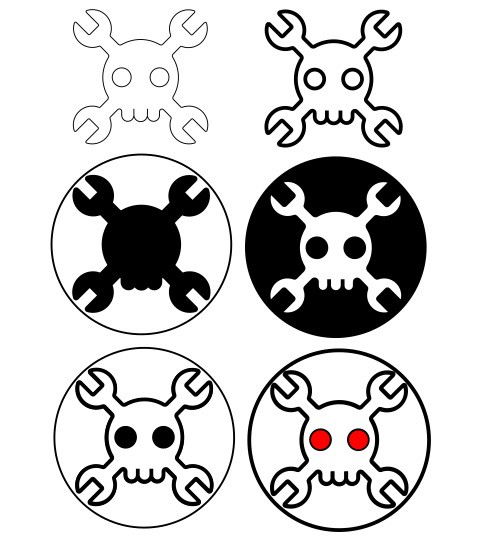

The upper left image is the 0.010mm width blue cut line for the laser cutter (No square corners).

The other five are me playing with different line widths to get an idea of what the cut pieces might look like. The cut pieces ended up almost identical.

The second is the actual laser cut width of 0.40mm (+0.20mm on each side of the cut line.)

The third is the skull subtracted from material, then material subtracted from skull, overlaying both, and last with the 2mm LEDs I ordered.

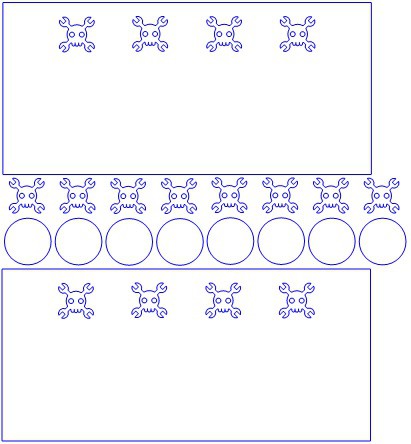

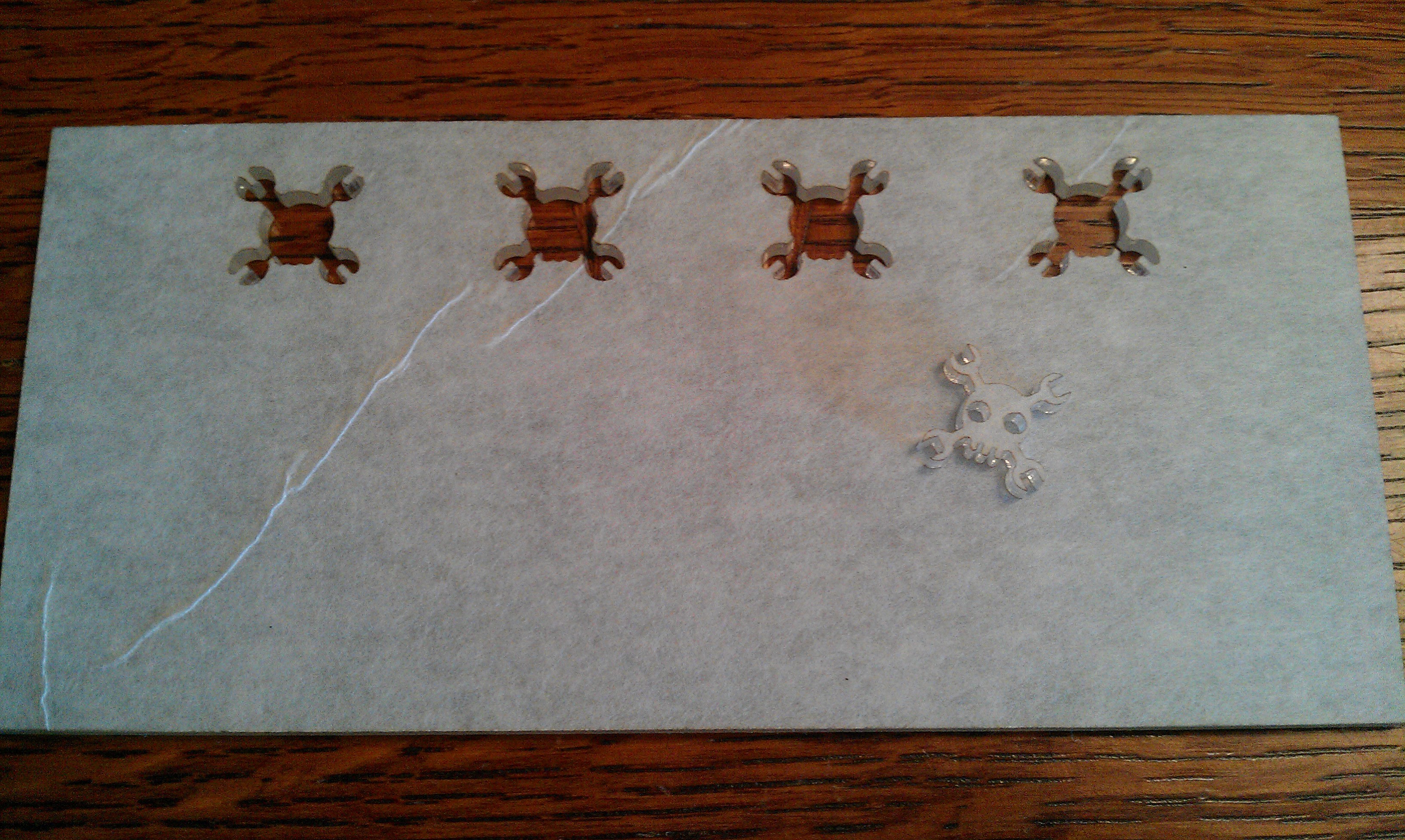

I made two test face plates 150mm x 70mm but without the USB holes. Also some extra skulls, as recommended in the Ponoko directions with tiny pieces (<5mm can fall through the bed.) Also some circles as bases to mount the skulls. I also found How to Make Snug Joints in Acrylic helpful to prevent cracking in the corners.

Cutting the inlays the same size made for a loose fit (0.4mm on each side). Next time I will get closer by cutting different size shapes outside the panel. Another mistake was not putting through holes through the circle bases for the LED leads, just like I did on the 3D prints also.

Inkscape vs. LibreOffice Draw

Inkscape shows the instructions outside the boarder,

and LibreOffice shows the actual drawing.

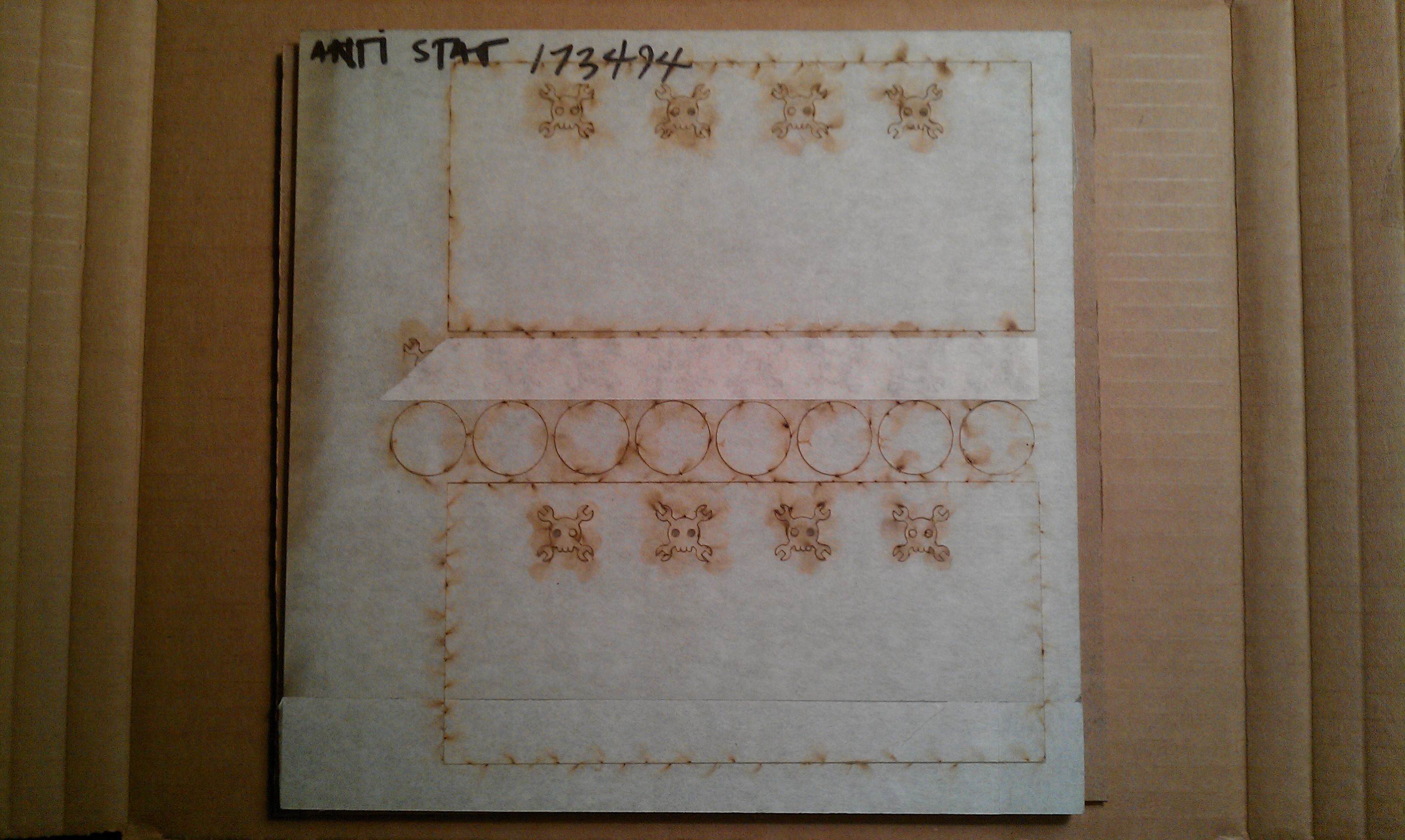

Adhesive paper holds parts in place. Scorch marks on paper only. This saved almost all of the 1.6mm diameter 3mm long cylinders cut out from the eyes!

Material and Cost

Ponoko recommends testing designs in cardboard for affordability, but I chose to see the more expensive 3mm anti static clear acrylic, 181 x 181 x 3mm (P1). The edges are sharp and clean all the way through.

It was three days for processing, one day to make and ship it, two day priority mail, making it six days total from idea to in my hands. $22 is $2 over the $20 discount, plus 9.55 shipping, means the total cost was $11.55. I made a few mistakes, but now I can order custom material inlays with more confidence for a variety of projects, so I would say getting my feet wet with this was worth it.

Some more test pictures:

These LEDs looked so much bigger on the computer screen when I ordered them.

This is with the paper backing on both sides:

Stacked and extended out 3mm past the panel:

Recessed 3mm into the panel:

Recessed eyes:

That's all for now. Back to the hardware until I get more case dimensions.

frankstripod

frankstripod

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

slick! Really? You think the cutter width makes them too loose? Have you measured the actual size after the cuts? I thought I read the cut-width was somewhat undefined...? Regardless: Looks pretty slick to me, those eyes are a nice touch.

Are you sure? yes | no

Thank you! Yes, too loose for direct inlays or size matching. The only reason this worked is because of the thick two layers of black spray paint. Cut width .2mm on each side of the cut leaves a .4mm width space. Cutting shapes out in place like I did leaves a .4mm space on each side of the shape, so .8mm wiggle room. The .2mm in the Ponoko directions doesn't sound like much, but for this example it adds up on small pieces. Sorry, no measurements; I desperately need some decent calipers. I would be happy to take more pictures if you need to see more details in the cuts, but obviously I desperately need a better camera also :)

Are you sure? yes | no

Also take a look at the skull picture (on the disc) under the title "This is with the paper backing on both sides". The space between the teeth must be the laser width. The disc is 19mm and the eyes are 2.4mm (2mm+.2 on each side) for reference. I should have made the eye holes 1.8mm to add up to 2mm.

Are you sure? yes | no

ah good point. I didn't catch that .2 adds up to nearly 1mm in that case... was thing .4 tops. Still looks fine in the pics... they're buttons eh? Supposed to be moved ;) daveyD seems to think the eyes look best sunk in..... maybe glue em in with epoxy? I love using tgat with a piece of tape to make smooth finishes.

Are you sure? yes | no

I was thinking of glue also. What is "tgat"?

Are you sure? yes | no

that... epoxy... typo... tiny onscreen keyboard. Epoxy+tape=fun. Tape over the front of the eyes, fill with epoxy, insert leds... smooth finish...

Are you sure? yes | no

That would solve the problem of dirt and dust in the eye sockets :)

Are you sure? yes | no

heh would also kinda defeat the eye SOCKET aspect which a skull kinda needs... now that you mention it.

Are you sure? yes | no

Great use of the free ponoko $20! Unfortunately I couldn't take advantage of it; my shipping costs on my case were $52 alone ha ha!

Are you sure? yes | no

Sorry to hear about the shipping again. I am grateful for where I live, but a little more now.

Are you sure? yes | no

It's not too bad, as i didnt have to pay an import tax on top of that; the screen I am using got sent to me for free and i had to pay £25 import tax, which is a big chunk of that $52 anyway. So all in all it could have been worse :-)

Thanks to the coupon i only had to pay £10/$15 for my case, so Im more than happy with that - any re-cuts I need doing I will find a UK based company to save on some of those shippong costs :-)

Are you sure? yes | no

Fantastic looking stuff, thank you for sharing! I'm an Inkscape fan, made a lot of my shirt designs with it. But in the end it's all about what's working out for you. I think the led eyes look best when recessed, with the dome being plane to the front. Now excuse me, I'm scrolling up and down a bit more :)

Are you sure? yes | no

Thanks for your input. I will experiment with that. Wait which one? The skull "Recessed 3mm into the panel"? or the "Recessed eyes"?

Are you sure? yes | no

the last picture shows the LEDs way in the head. How can I describe that best - lay the acrylic skull on a table and push in the LEDs?

Are you sure? yes | no

Yes, the last one. I was thinking of painting the eye sockets black.

Are you sure? yes | no