The complete tutorial is available on my blog, but even if you're not interested in airsoft or looking up bomb tutorials online, there are a few design choices which I feel are good to consider when designing a product that will be thrown around.

- Choose a good material to print. ABS has worked well for me (for parts of this size, I usually put the extruder 10º higher than normal to improve adhesion). PLA is too brittle. Other materials such as nylon or Filaflex might work.

- Notice the two threaded rods in the picture above? They are meant to join the two halves together and keep them compressed so that no external forces manage to pull layers apart. And even if the layers break, the grenade will remain whole so that you can try to superglue it later at home.

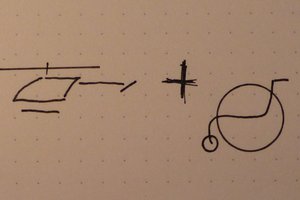

- I scratched the pin and lever mechanism. It was too weak and broke on every iteration I tested.

- In the perfboard, there is a coin cell battery fitted inside a battery holder. The instant the grenade hits the floor, contact between battery and battery holder is lost multiple times due to vibrations, even if it’s just for a fraction of a second. This causes the microcontroller to lose power and reset, so the program resets and the explosion never happens. I solved this by soldering a 220 µF capacitor between positive and negative, which acts as a power buffer during those interruptions (a filter, basically).

- The board is dangling inside the enclosure, with the cables acting as dampeners for the electronics. Usually this is a very bad design choice, because cables are not made to dangle or be under stress (the solder joints may break), but for an application like this it has been reliable enough.

- A pushbutton has moving parts inside which may break after a good hit. After having trouble with others I tried the one listed below, which gave good results while still being cheap. They’re not really heavy duty but for now will do.

Eduard

Eduard

krkl

krkl

FromWasteToWind

FromWasteToWind

Madaeon

Madaeon

Matt

Matt