I promised more updates this weekend and well here it is! I spent a good amount of time finishing the grow lights. So on the grow light after the painting on the outside was finished I took to painting the inside of the light. Originally the plan was to use tin foil or a mylar space blanket for reflecting the LED light down towards the plants, I decided that eventually there will be so much LED strip applied to the inside of the light that all reflective material will be covered. I decided to paint the inside white and scuff the surface of the paint after drying to allow for better adhesion of the LED strips to the surface of the inside of the light.

Starting the first coat

Almost done with first coat

More progress:

First coat finished:

Starting the second coat of paint:

Finishing second coat:

After letting the paint dry and cure all day I took to scuffing it up with sandpaper for better adhesion of the adhesive on the LED strips. I used 330 grit sandpaper, its my usual go to, its a nice compromise between fine and coarse. Of course if I were trying to get glass like finishes I'd be using all sort of paper but for this project, keeping it simple.

Cleaning off the sanded paint with a rag and rubbing alcohol

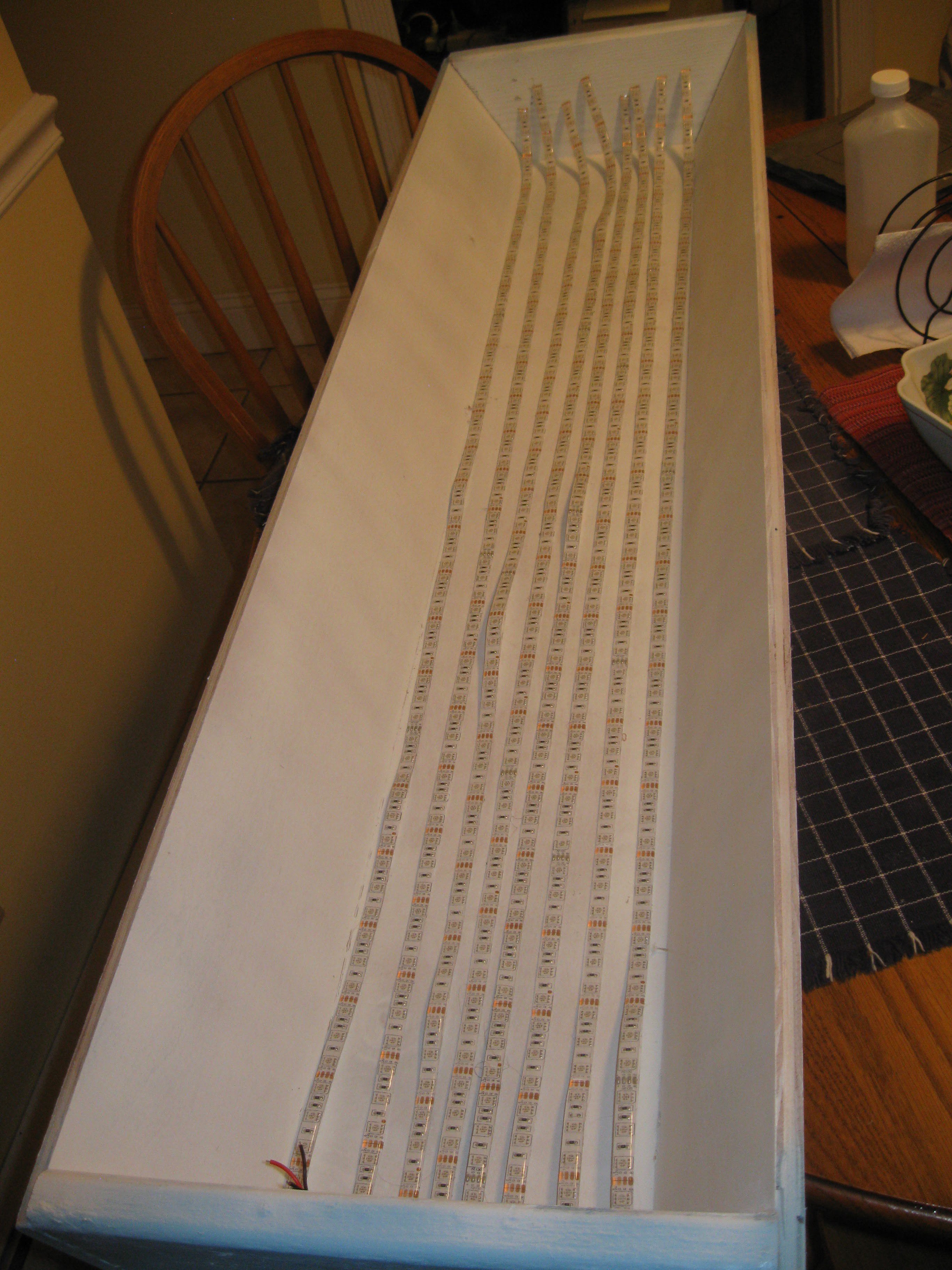

Next off I began to mockup the light casing with the strips in preparation for assembly. The mockup consisted of carefully placing the LED strips spaced apart in the light casing. Originally the strips were cut to approximate 4 foot lengths, but since the ends of the light casing are inside the case I lost some room and had to shorten the strips a bit.

LED strips on their reels in the packaging they came in. Even though I cut them a while ago I still rolled them back on the reel for storage.

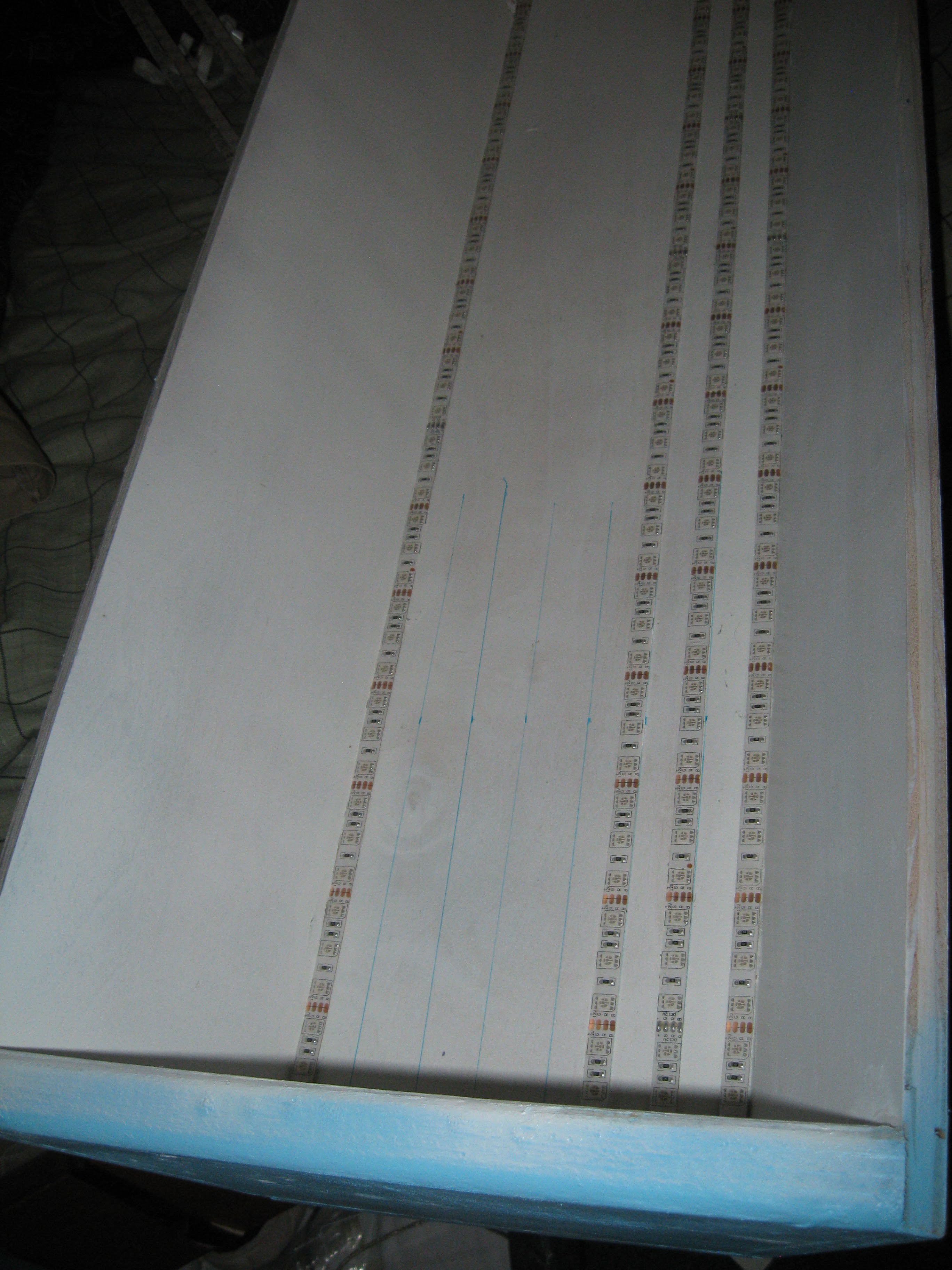

As you can see in the pictures there was a bit of excess strip on each length, I cut them at the marker, making the strips fit with enough room for wiring. I have been collecting the small bits of strip and saving them because when I get more strip there will be more leftovers, the idea is that I can join them all together and maybe get a few more lengths from just the scrap. Next off I used a ruler and sharpie to mark the spacing of the strips on the light. I did it at each end and lined it all up by hand.

Lines drawn and some strip applied, the lines that the edge of the strip lines up with are spaced and inch apart, this gives enough space to put down more strips later to upgrade the light.

Close up of the strip application and markings:

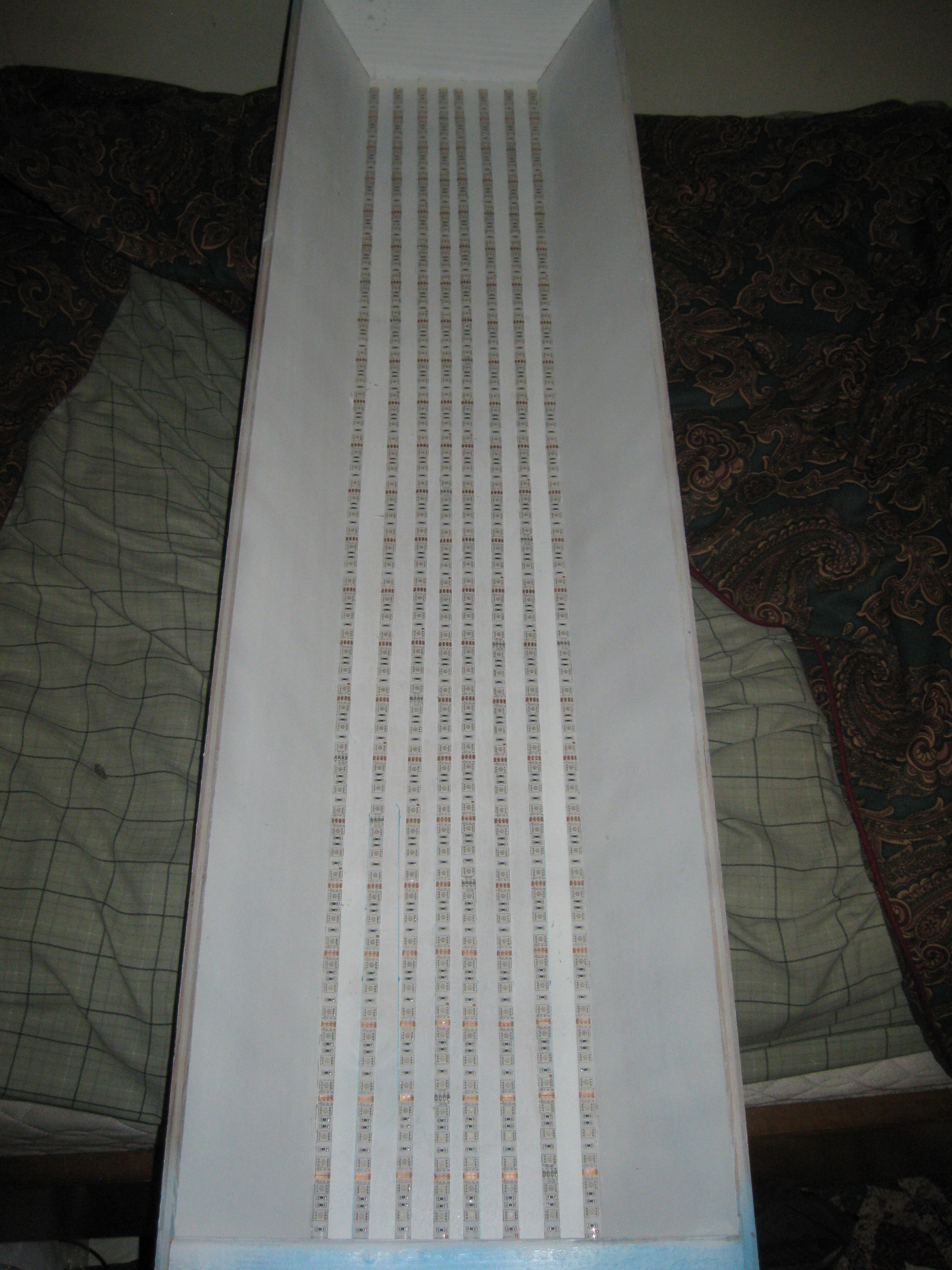

All strips in place along the marking. Eventually there will be strip on the outer sides and more in between. This light is the first prototype so I need to evaluate the LED strip I chose and figure out whether or not I need a different kind.

Next off was the process of soldering the LED strips to wires so they could be fed with the 12 volt 240 watt DCDC power supply I selected. As can be seen in the picture the adhesive on the LED strip isn't too great so they will be hotglued in place to help keep them attached to the light. As for the power-supply it is to be mounted on the front end of the light, holes will be drilled to get the wires through to the power supply.

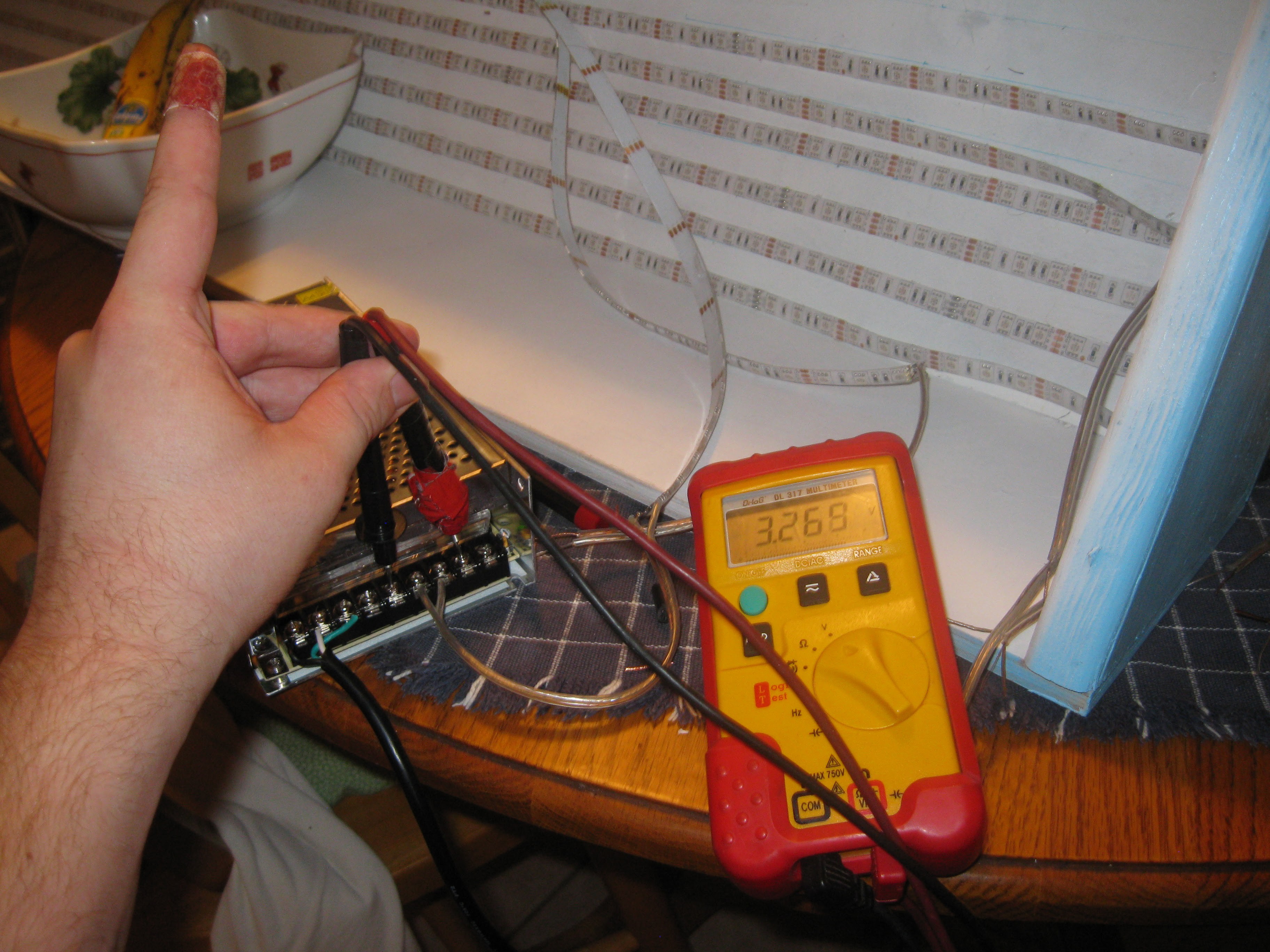

Upon wiring up the power supply I bought I discovered a problem with it. For some reason no matter what position the trim pot was turned to the PSU would only output 3.1-3.2 volts, which is completely wrong, its supposed to be in e range of 12 volts and then some. I've used similar PSUs to this one so I have no idea whats wrong other than it was mislabled as a 3.3v PSU or its defective. You can see in the picture that the PSU is not outputing the correct voltage, also notice that nasty cut on my finger, I don't recommend ripping apart AC Power cables with a pocket knife!!!!!

I contacted the seller and hopefully I'll be able to get a replacement soon. In the meantime a friend is gonna lend me a benchtop PSU to run the light until I get my new one. Stay tuned for more !

AVR

AVR

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.