Building Shapeoko 2

From a box of parts to a working desktop gantry style CNC mill

From a box of parts to a working desktop gantry style CNC mill

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

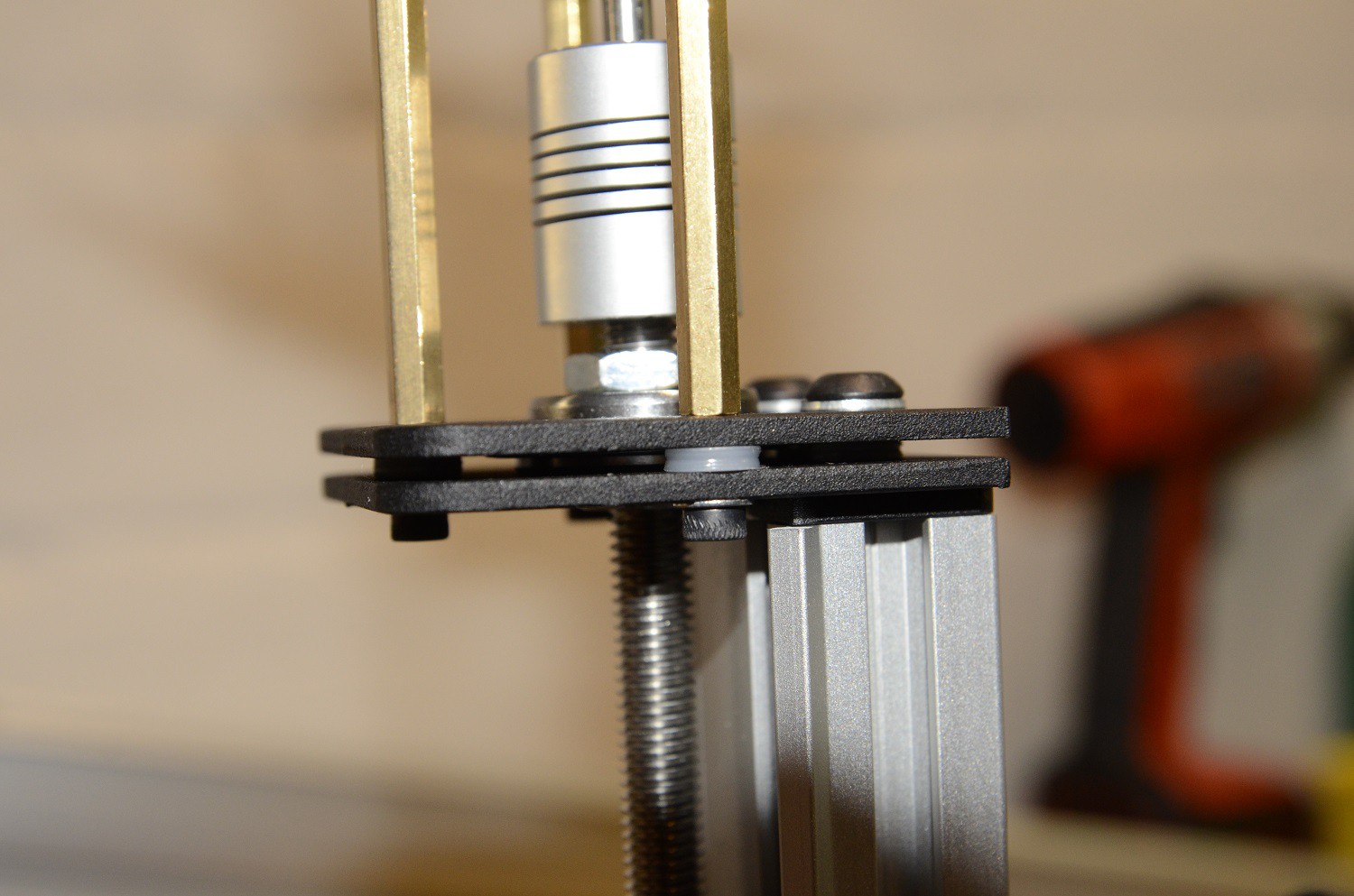

The Z axis is the most complex step so far. The hardest part has to be the Z motor mount plate. Screws going in from both sides, thin nylon spacers stacked between the two plates, and a flange bearing in the middle. This thing was kind of evil to assemble.

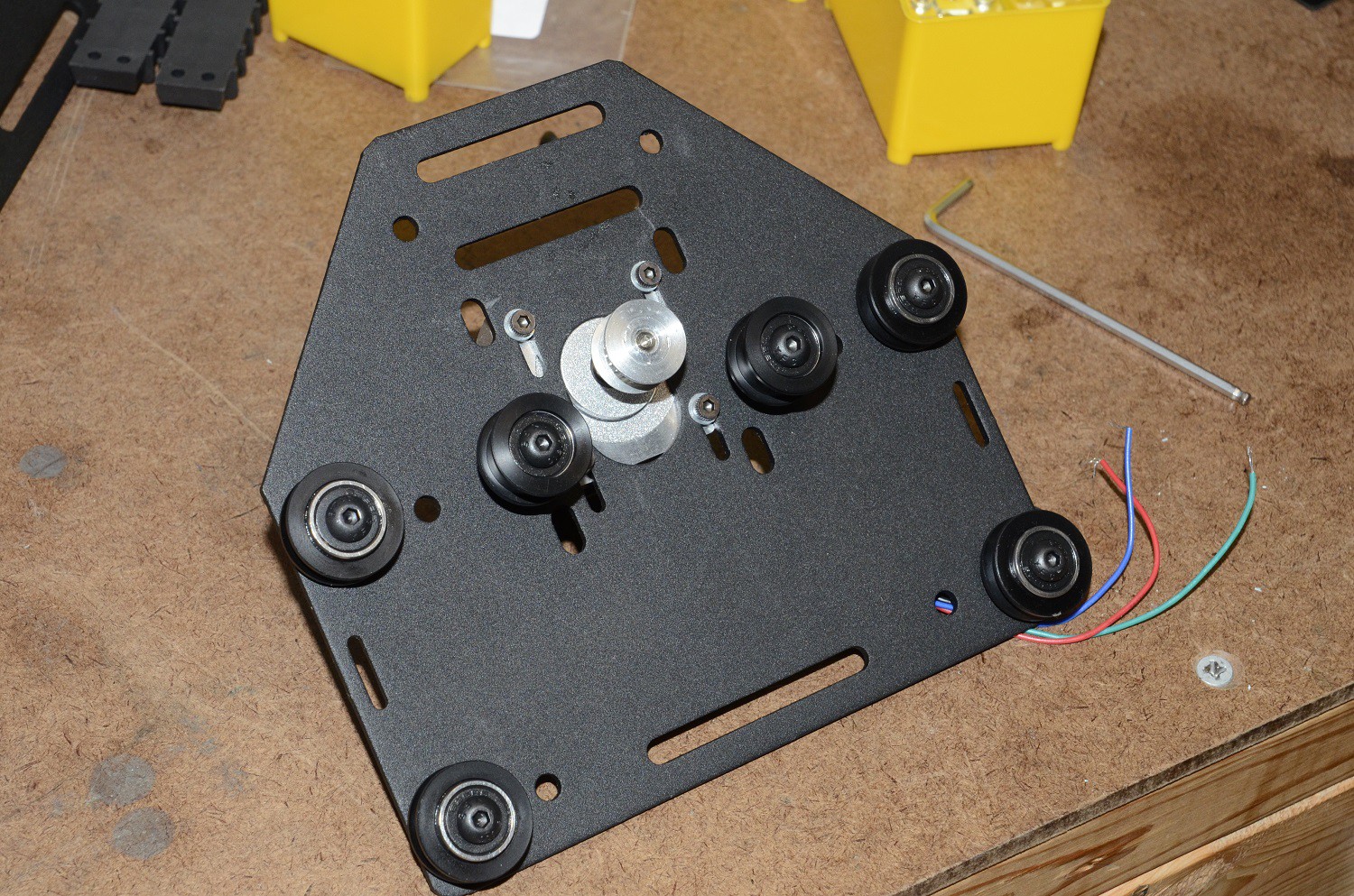

The Shapeoko 2 assembly continues with the carriages. The carriages are laser cut sheet steel, and need a whole bunch of parts screwed into them. Motors, V-Wheels, Smooth Idlers, everything goes in. The manual is silent on aligning the pinion pulley with the belts, so I did my best. Hopefully when the belts get installed I won't be too far off.

There are  There are three carriages to assemble.

There are three carriages to assemble.

I started with cleaning off my rather cluttered workbench, and laid out the parts for the S2.

The S2's assembly starts with the V-Wheels and smooth idlers. Each one has two bearings, a spacer or washer, and a Delrin shell. Everything presses together, but you really need to have a screw in in the center to hold that center washer in place.

There are a lot of these. 20 V-wheels, and 6 smooth idlers.

There are a lot of these. 20 V-wheels, and 6 smooth idlers.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

any chance I could get a parts list. I would love to make one