Ongoing project, see log for progress. Description will follow later.

For now some links:

Building a electriconic wheel truing stand, which makes whel truing easier.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Ongoing project, see log for progress. Description will follow later.

For now some links:

Using a pencil and a rubber band you can build a very fast and easy but also very helpful truing stand. Only disadvantage: you might want to clean all the pencil lines off the rim after the truing work is done.

A wooden stand and a dial indicator gauge can become a very accurate truing stand as many many people have done already (see also here and here). Not DIY but another version which looks very promising, because you do not need to get the wheel out of your bike.

Brake pads (if your bike has rim brakes) or really everything can be used. Also clothespins or mini-clamps seem to do a good job (crayon is a usefull marker by the way).

There is a list of 7 nice DIY truing stands abt bikehacks.com.

If a truing stand does not help, you might want to follow these instructions. A truing stand might be useful later on to do some fine adjustments.

This catalogue from the early 1980ies has a nice electronic truing stand (as well as mechanical ones).

Other useful tools when truing a wheel include:

Some more links and pictures.

Using common wheel truing stands you have to find the biggest error by visual judgment. Usually you use calipers while turning the while to find a lateral rim run-out. If you have difficulties to find the problematic rim position with naked eye it might help you to move the calipers until one side begins to lightly scrape the rim. However this method is not possible if you turn the wheel slowly (you cannot hear the scraping), but by turning the wheel fast it is not easy to find the position.

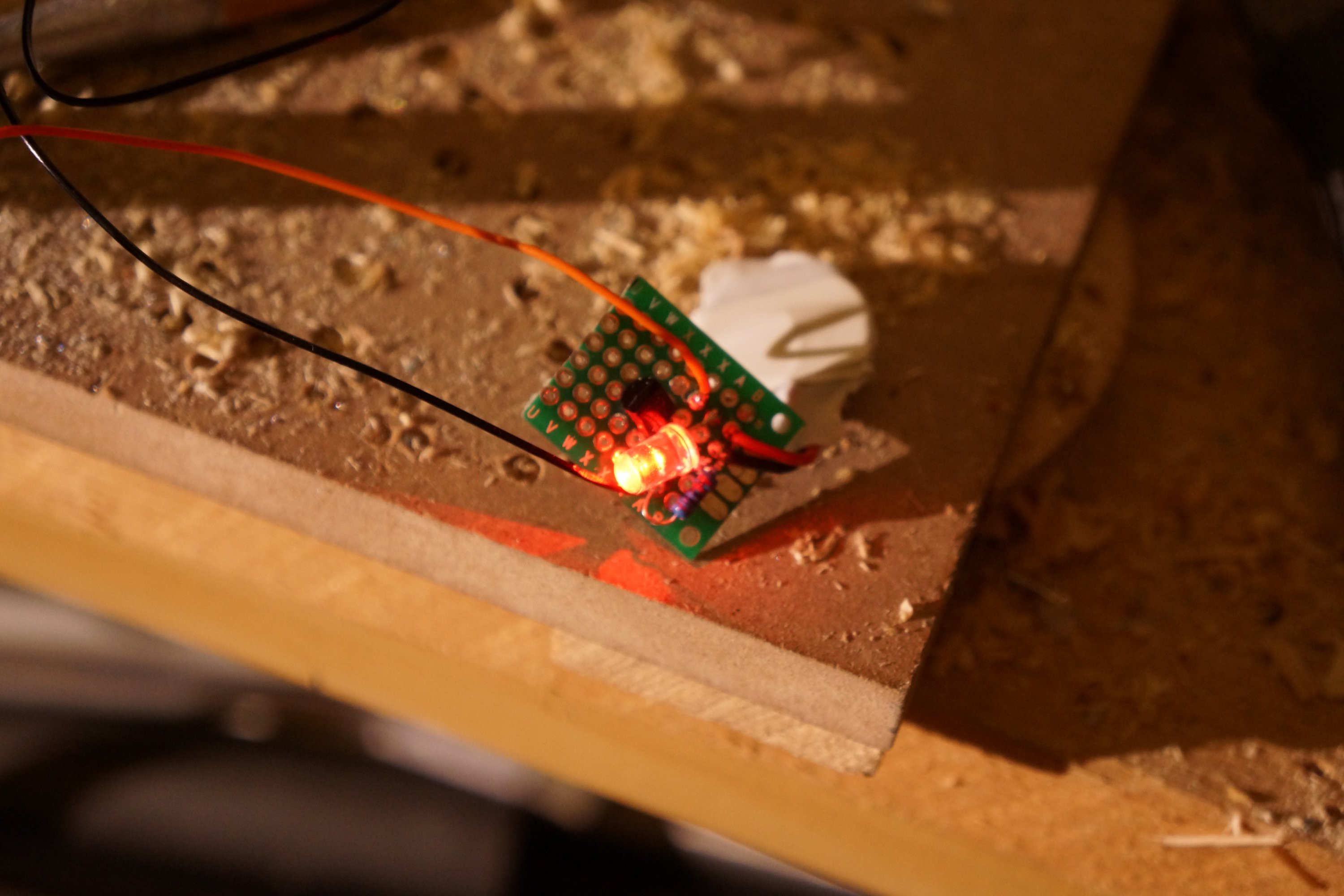

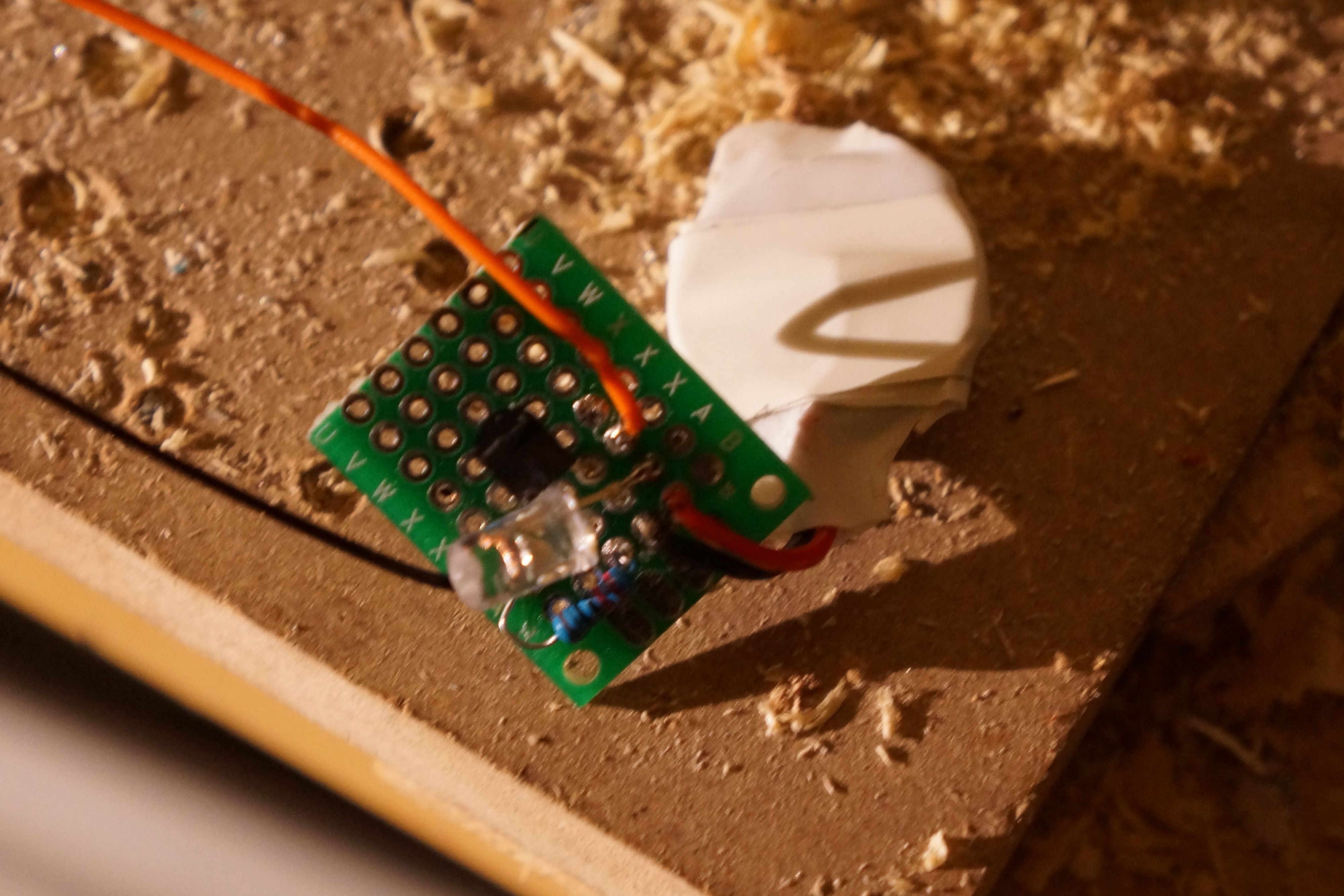

That is why I started to use electric conductivity to measure the distance between caliper and rim. This post shows a first and very fast prototype to test the idea. I am not sure yet how I want to continue. I think it would be nice to have a very compact tool which can be mounted directly on the bike (fork or frame) or to build a stand for all available sizes of hubs. If everything works fine, I want to try moving the calipers using small stepper motors or servos. A micro controller could assist unexperienced mechanics.

As first test I used:

Two cables are connected to the circuit. One is connected to the screw (touching eventually the rim) and the other one is connected to the fork. The transistor makes the LED light up bright also if there is a high resistance between the two cables. I can turn the screw slowly until it touches the rim and the LED lights up.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates