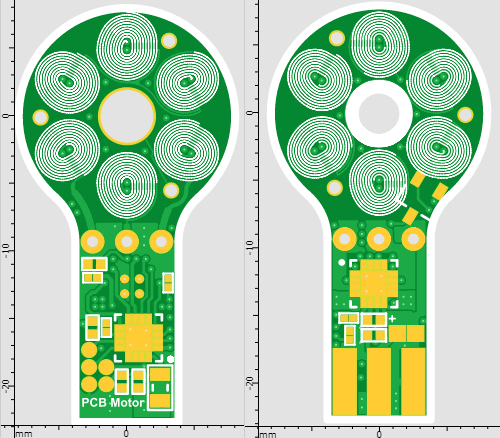

I finally ordered a new PCB motor with an integrated ESC. I have managed to package the circuit in a very small space, 30x16mm including the stator. For now I have ordered the same star winding configuration that i've used in the first prototype. I'll be ordering more configurations soon.

The circuit basically consists from:

Hall Sensor (US1881) to detect the magnets inside the rotor.

- MCU (PIC16F1503) - I have shifted from the DSPIC33EP128 to the PIC16F1503. This MCU has less computational power (not much is required since I am no longer considering sensorless control) but is packaged in 3x3mm chip and is around $2 cheaper

- 3-Phase Motor Driver (STSPIN230) - which is rated at 1.3Arms, and has several types of fault protection build-in.

- A filtering circuit to supply the micro.

I will upload all the source code and gerber files once the PCB arrives and verify its functionality. Keep tuned!

Carl Bugeja

Carl Bugeja

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Seriously cool! I love that you switched to the lighter chip. Stupid questions / suggestions that you have probably already seen from 1000 other people, so don't feel any rush to answer them:

1. How do you program the chip? I assume the ICSP pins are brought out? Probably the 5 circular pads in the lower left?

2. With a bit of extra space, you could make that end USB compatible (for power) and with an e.g. CP2102 and a bootloader it would make development easier. Which is probably not worth the effort, but might be nice for people who don't have whatever adapter you are programming the chip with.

3. How are you mounting the central shaft? Can't be a bearing... bushing? Or is it just using the PCB as a side load bushing? At the higher speeds, an air bearing might be possible with ducting milled into the PCB hole. That's a REALLY crazy idea. Or a 3D printed fan/duct on the back side.

4. For more power (MORE POWER!!!!) it will need to be stacked, right? So having some way to interconnect the windings from one PCB to the next layer may be a good idea for future. Or is that the purpose of the three through holes near the windings?

Are you sure? yes | no