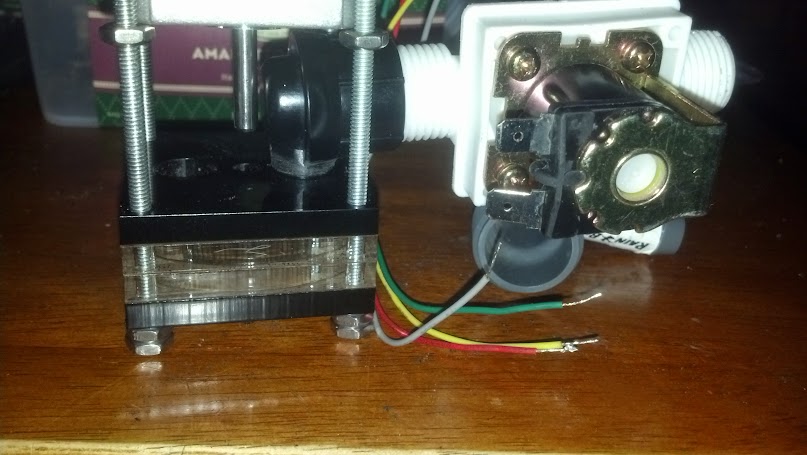

Here it is with the inlet and solenoid valve, and the motor just resting on those nuts. It will be pretty easy to cut and drill a motor mount by hand. The inlet was, of course, too big for the holes and had to be hand sanded down to fit. Note to self: Buy and measure the hardware FIRST, THEN design the part. Just because the catalog says the part fits a 1/2" hose, that does not mean it's actually 1/2". They make them bigger so the hose has to stretch a bit... plexi doesn't stretch.

Here it is with the inlet and solenoid valve, and the motor just resting on those nuts. It will be pretty easy to cut and drill a motor mount by hand. The inlet was, of course, too big for the holes and had to be hand sanded down to fit. Note to self: Buy and measure the hardware FIRST, THEN design the part. Just because the catalog says the part fits a 1/2" hose, that does not mean it's actually 1/2". They make them bigger so the hose has to stretch a bit... plexi doesn't stretch. Better view of the chamber. I still have to figure out a way to get the stirrer attached to the motor shaft. Prolly just a coupler to another shaft, but then I'll have to file or grind the shaft flat where the stirrer paddle attaches to it. And I need to trim down the outlet 90' adapter and attach the flow rate sensor. Then it's Lights! Camera! (well... photosensor) and Action! (well... moving the stirrer and controlling the valves, etc... )

Better view of the chamber. I still have to figure out a way to get the stirrer attached to the motor shaft. Prolly just a coupler to another shaft, but then I'll have to file or grind the shaft flat where the stirrer paddle attaches to it. And I need to trim down the outlet 90' adapter and attach the flow rate sensor. Then it's Lights! Camera! (well... photosensor) and Action! (well... moving the stirrer and controlling the valves, etc... )

First Trial Assembly

A project log for Reagent Robot

Automate the Reagent (take a sample, put a drop of stuff in, shake, look at the color) testing of water for Aquaponics, Ponds, Aquariums.

James Newton

James Newton

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.