So far this year we've done a lot better, the kits are all made, speaker and staff badges are all built, and i'm putting together a bunch of the LED badges. I'm using the TM-220A pick and place, and actually getting it to run.

Using DP-TM220A.ulp for eagle from Dangerous Prototypes. The first issue i ran into was that the rotations are different, after some poking around I realised we'd had this problem with our PickoBear PNP at NSL, that Eagle doesn't use an absolute rotation, the rotation the ULP sees is relative to the the rotation of the part in the library.

Hmm not good..

So i went through each of the parts manually and fixed the rotation myself. The firmware is a bit flaky and it crashes a lot on malformed files, i ended up using a Chinese formatted file to handle it.

After that i did a run in single step and the rotation was a bit off and needed manual touch off, and on a full run the rotation got even worse, so i changed the machines speed to 50% and it rotated perfectly, so probably either the vibration or the nozzle size is too small, i've pulled out the nozzle pack and will try a larger one.

Another thing we did, was to cnc out a chunk of aluminium put a couple of metal pegs in that matched the holes of the badge and put it on the bed of the PNP , the existing holder is not good at all. So now i can pop the board on, use the paste stencil, remove the stencil and run the pnp, take it off and put it on the hot plate. so far so good!.

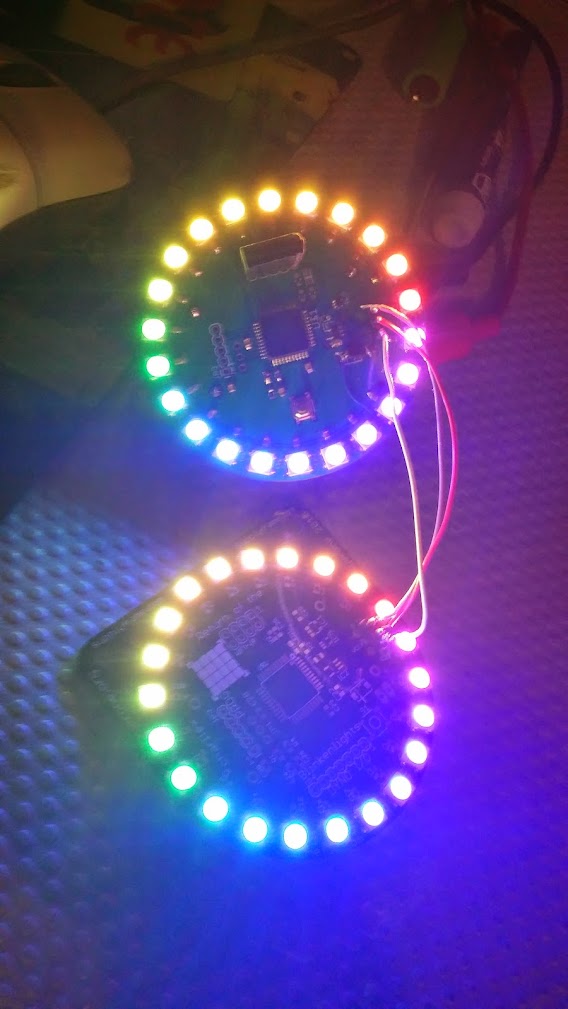

The badges are also chainable and they'll even run in parallel. Here its passing over VCC,GND and the logic output to drive the WS2812's.

So close to the right number....

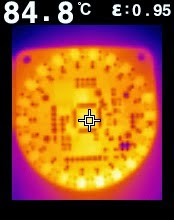

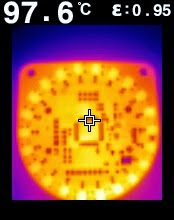

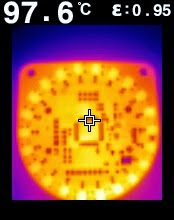

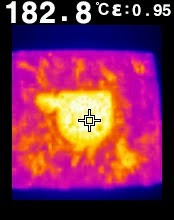

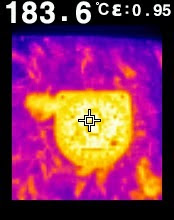

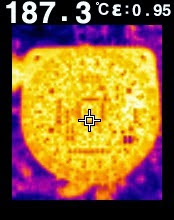

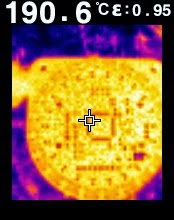

hotplating at 176 setting

of course if you have one, there are always reasons to use it

\

\

Robots!

charliex

charliex

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.