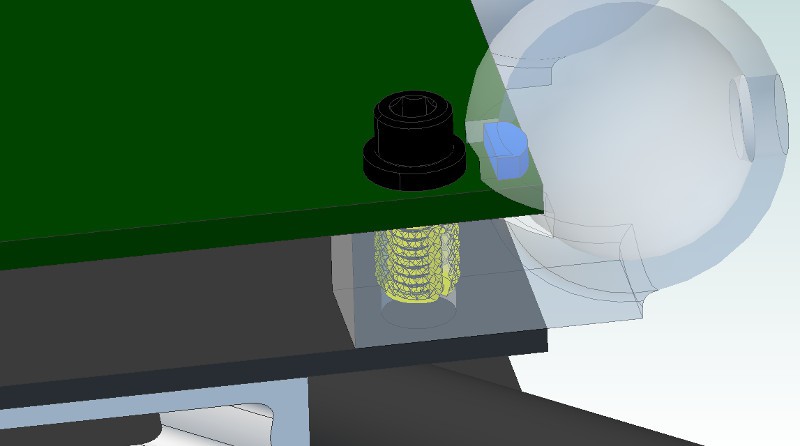

Figuring out how to get the various chassis layers to stay together was a bit of a puzzle; I wanted to use tiny socket head cap screws to allow full disassembly, but I also didn't want to drill holes through the arms. Trouble is, the mounting holes on the PCB line up with the arms when everything is centered.

Solution? Press-fit inserts and glued-down SLS parts!

McMaster has a nice selection of 0-80 hardware, so finding these bits wasn't too hard. They also have solid model files of most hardware items, so getting everything into the model was a synch.

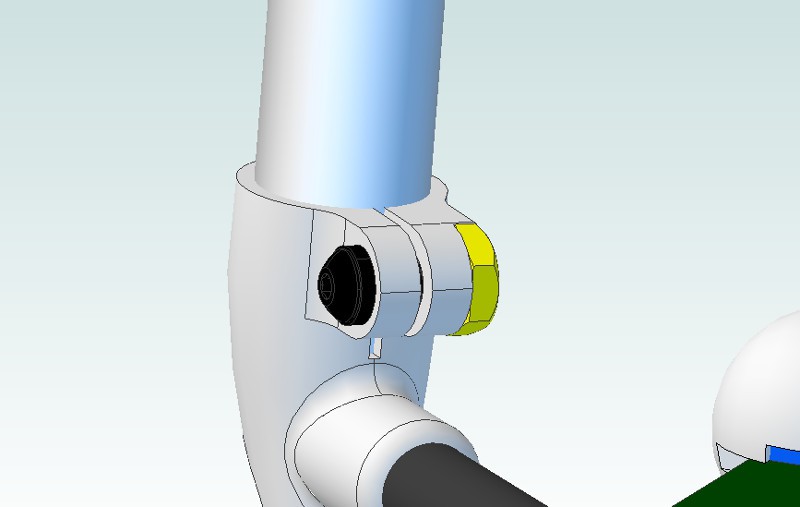

I also reduced the size of the motor hardware down to 0-80. Brass nuts for extra awesomeness, and a bit more curve on the loft:

I updated the v03 model to include approximate material densities; based on this info, the finished frame minus props and battery should weigh in around 23g or so. A bit of Internet research suggests that should be a ~20% reduction, so... we'll see how it flies in a few weeks.

zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.