The next batch of 250 kits is coming up. Just while I was enjoying VCF MidWest, I got bad news: the manufacturer mailed to say that actually, my switches had not been/would never be shipped. Their production molds were broken. OK... but I had just ordered 250 PCBs and front panels, which depend on the exact measurements of this particular switch. Ouch.

Lesson 1: use standard parts. This one was non-standard, used by the Chinese military 10 years ago. Or something. You only find out afterwards...

Lesson 2: if you buy cheap, get the parts in your hand before planning further.

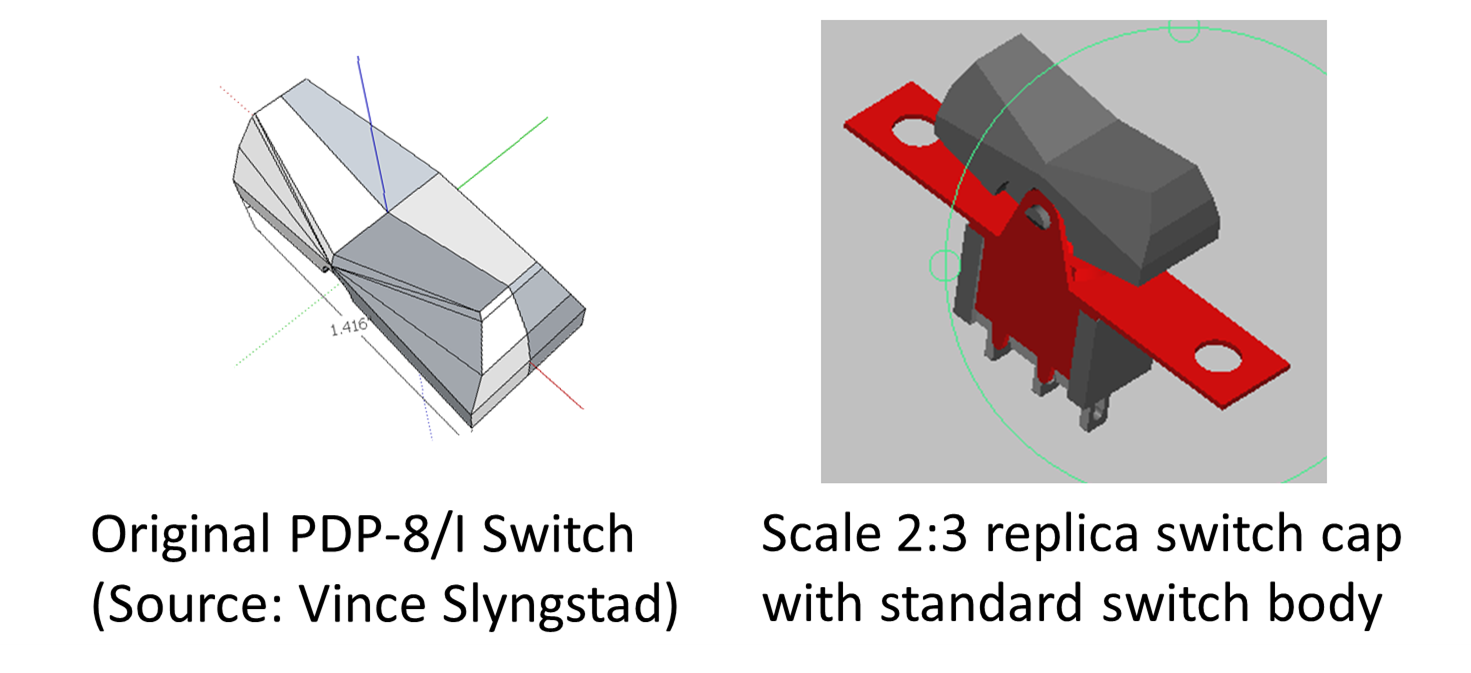

After three weeks of solution-seeking, things are looking up with the surprisingly helpful switch manufacturer! I will have to ditch the PCBs I made, but a new standard switch with custom-made switch caps is in sight. Custom-made... I learned some about that as well, because I had a go at a custom 3D design for the replacement switches:

Lesson 3: Making a 3D design of something simple like a switch cap, then have it implemented on the other side of the world is not trivial. Not cheap either. And if you're a hobbyist, you quickly learn of the pitfalls of precision design. 'Nuf said... I have to wait and see how the new switches turn out. Manufacturing time is a month.

Oh well. I can still do a run of kits in October, and then I'll have to take six weeks to respin and test a new PCB. At least I now have switches with standard footprints.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.