Since I was re-printing everything anyway due to the heat damage, I decided I would try to print all the parts at 0.3mm nozzle size. Well actually, I consumed my last 0.4mm nozzle a while back so this was more a choice of attrition.. but anyway, 0.3mm nozzle it was.

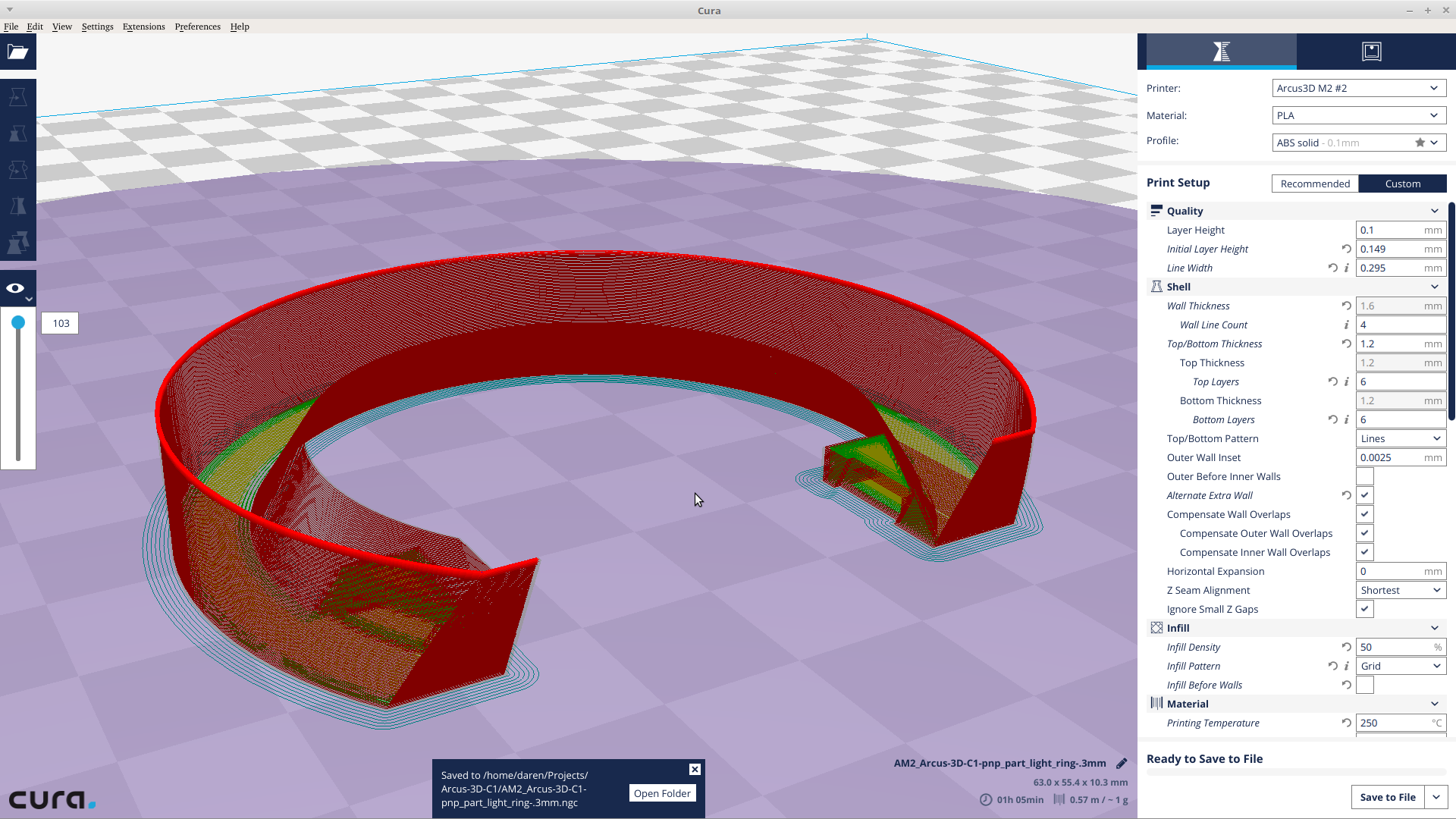

Due to my previous haste, this required far more modifications than just changing the variable representing nozzle_dia in my code. There were a lot more things dependant on nozzle_dia than I had accounted for, such as the ultimate thickness of the single wall print of the part_light_ring. At 0.4mm this was still within the range of rendering a wall for Cura. At 0.3mm, it was not.

A couple failed prints later I realized that 0.3mm at a 45 degree angle was too thin, so it was stopping the rendering half way up for the angled bits and renderings those areas just exceeding the threshold as a bunch of partial lines. I was firmly in the area of mathematical rounding for determining if a single wall should exist or not.

This of course, made a complete mess. Doing partial lines for a single wall print just doesn't work.

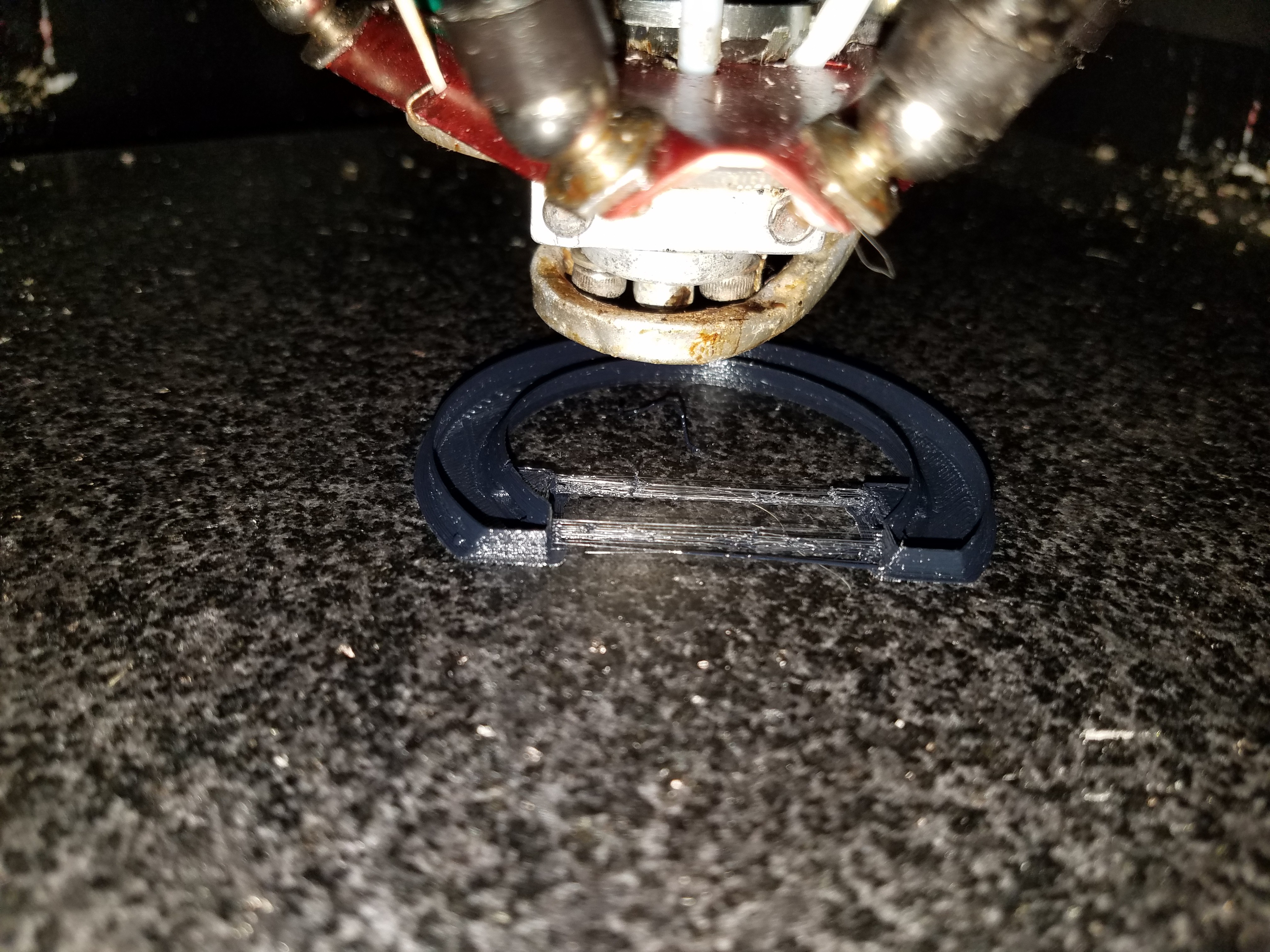

I multiplied the wall thickness by 1.44 (45 degree angle horizontal thickness for a 1.0 vertical wall thickness) for those areas, and now have good code again.

Looks like this worked.

Second to last part to re-print, and I'm back in business.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.