Spent some time refining the model for the 3D printed vibration isolators today. It's a lot easier to print now.

I cut one of the failures in half so you can see what it looks like on the inside.

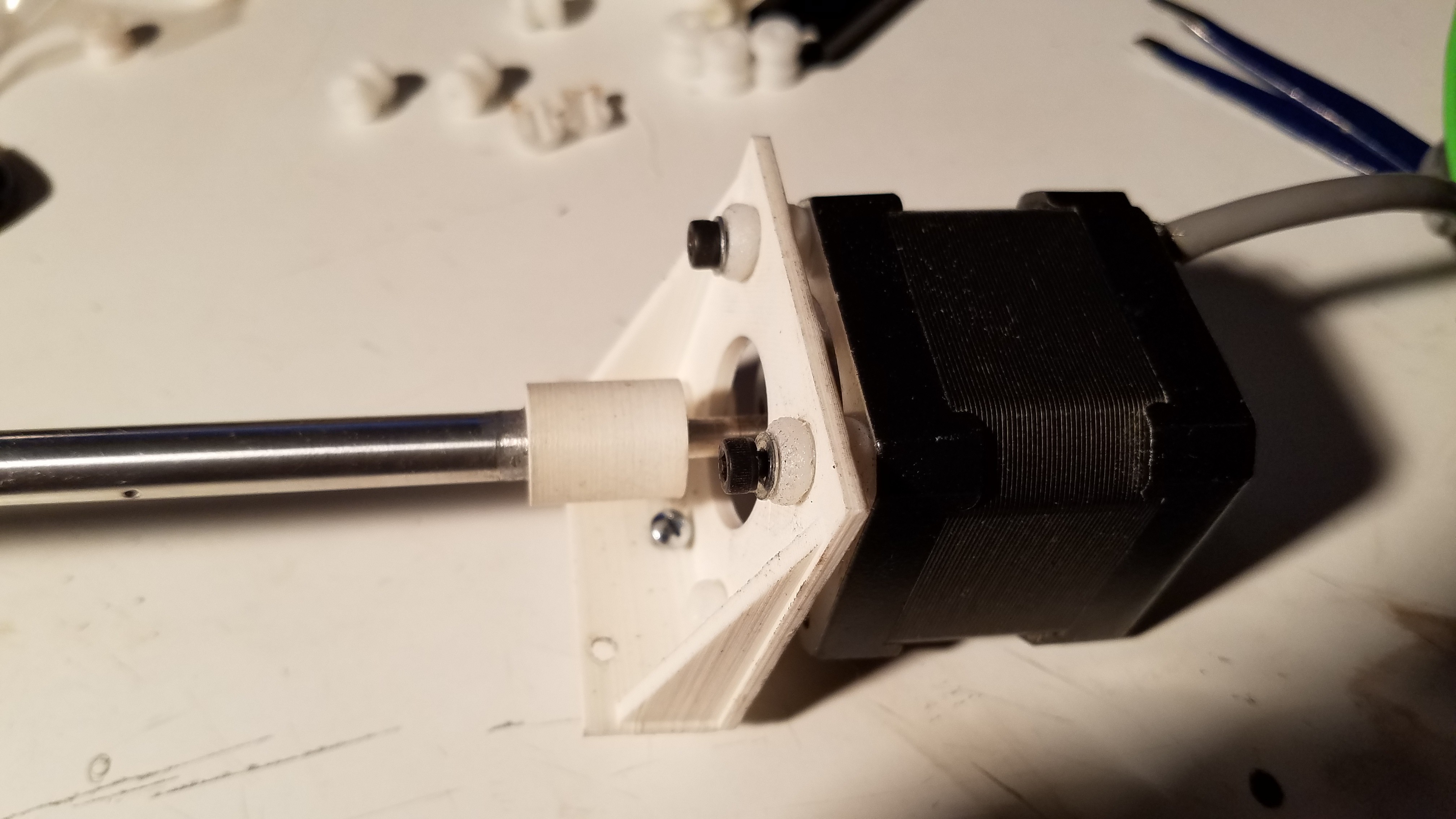

They fit in the oversize mounting holes on my stepper mount.

Sliced in Cura set to 1 wall, 2 top/bottom layers, no infill, and over extruded by 20%

I fit all the parts for the base today, then disassembled it again. The second coat of lacquer is drying now.

Assembly tomorrow.

EDIT: A day later, and the paint is still too soft to work with it.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.