So, here are some experiments I've done with etching the aluminum negative for the glass plate.... I've converted over 100% to chilipeppr.com since it turns out to be awesome... I've been using the Eagle .brd import feature....with the following settings...

Inflate Milling Path By: 0 Advanced Inflating Inflate SMDs By checked -0.12 Clip wires unchecked Remove Undefined SMDs unchecked Inflate Pads By checked -0.1 Inflate Vias By unchecked 0 Depth of Milling Traces 0 Feedrate for Milling Traces 400 Feedrate for Plunge into Copper 800 Clearance for Z Axis Moves 0 Depth of Cutting Out Dimensions 0 Step Down for Cutting Dimensions 0 Feedrate for Cutting Dimensions 400I skip the send gcode to workspace step... copy the gcode from the textbox... I then paste that gcode into a text file...I use a .tap extension... And run a overly simple python script on it to insert my M3 and M5 commands to turn the laser on and off instead of moving the Z Axis.... Here's that code.....it's not great....

import os

os.remove ('new.tap')

outFile = open('new.tap', 'a')

with open("mcu_panel.top.etch.tap") as f:

for line in f:

if line.find( 'Z-' ) != -1:

outFile.write("M3" + chr(13) + chr(10))

print ('M3')

if line.find( 'Z0' ) != -1:

outFile.write("M5" + chr(13) + chr(10))

print ('M5')

outFile.write(line)

print (line)

outFile.close()

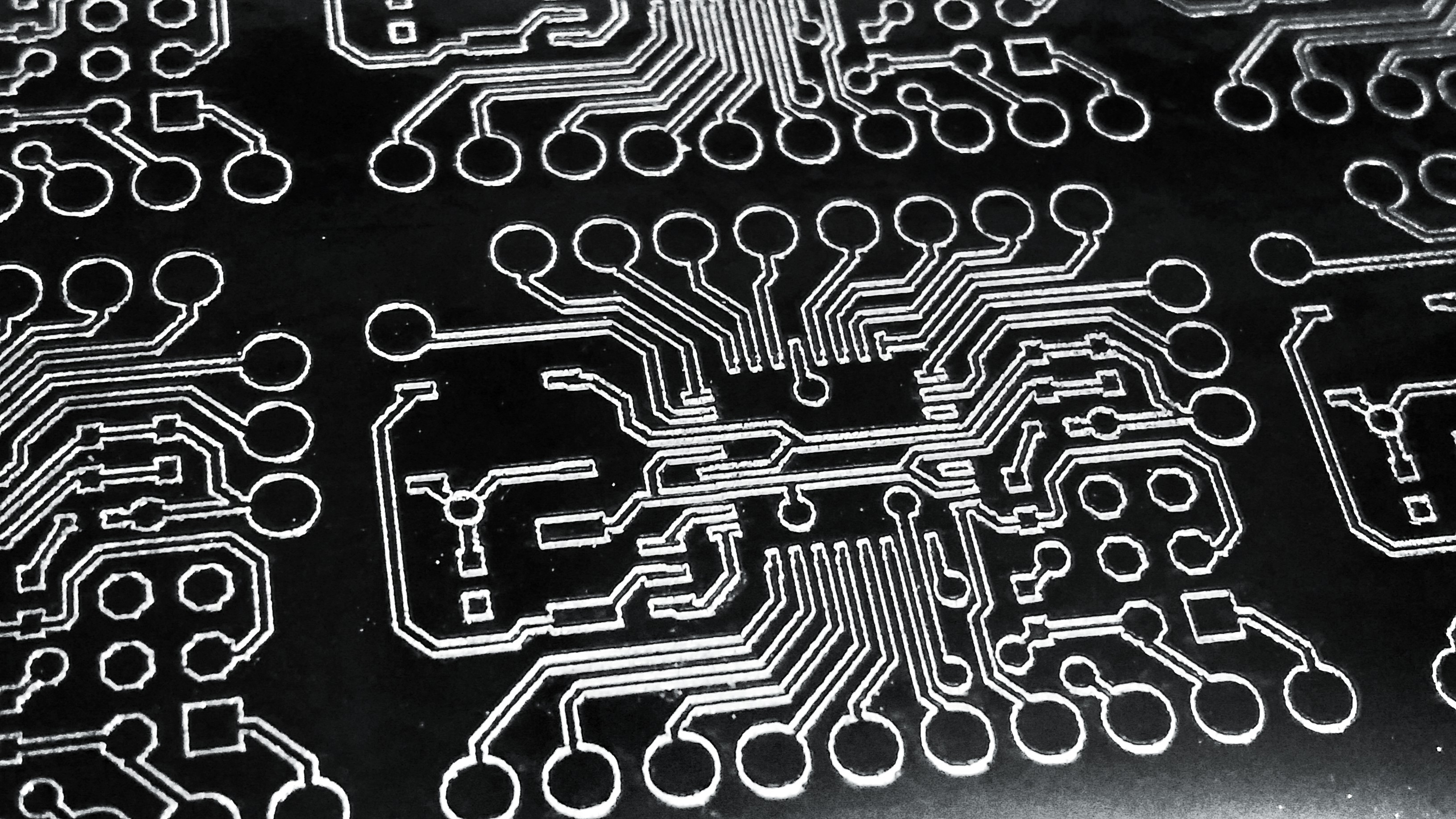

I then take the new.tap gcode file it creates (I also remove the dimensions section since I haven't added that to the code yet) and drop it back into chilipeppr.... Hopefully this can be streamlined later...but it certainly works for now...This is a TQFP32 for an atMega328.. This is the glass plate with a layer of aluminum tape and a layer of adhesive vinyl on top of that...then cut with a 1w 445nm laser at 400mm/sec... A panel of these goes in about 5-10minutes...

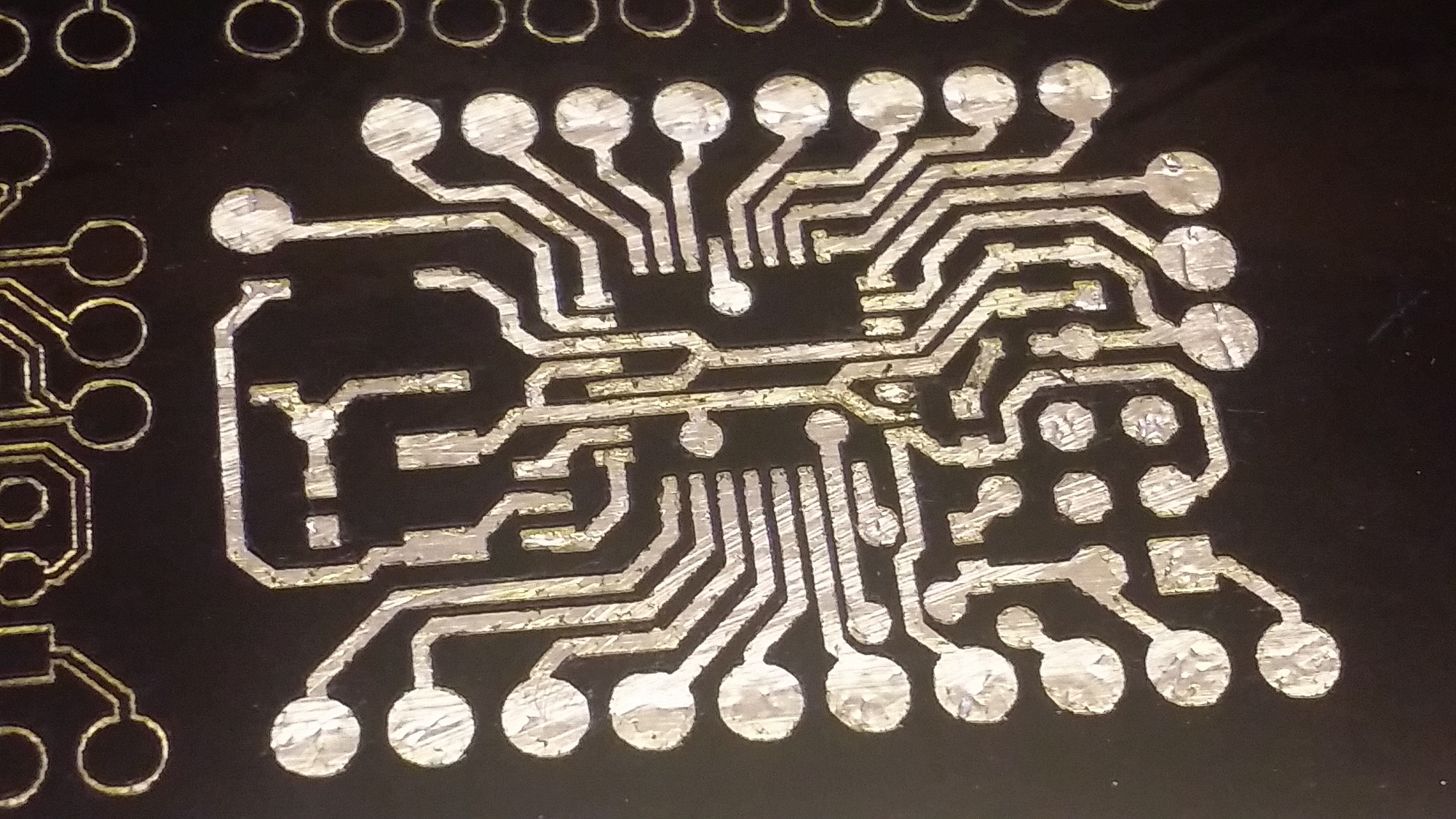

Here is the same board with the vinyl removed... Take note that this step only has to be done ONCE... After you've done this, then etched the aluminum you'll have a template that can be used indefinitely... Treat it right and you'll never replace it..having used it over and over again...

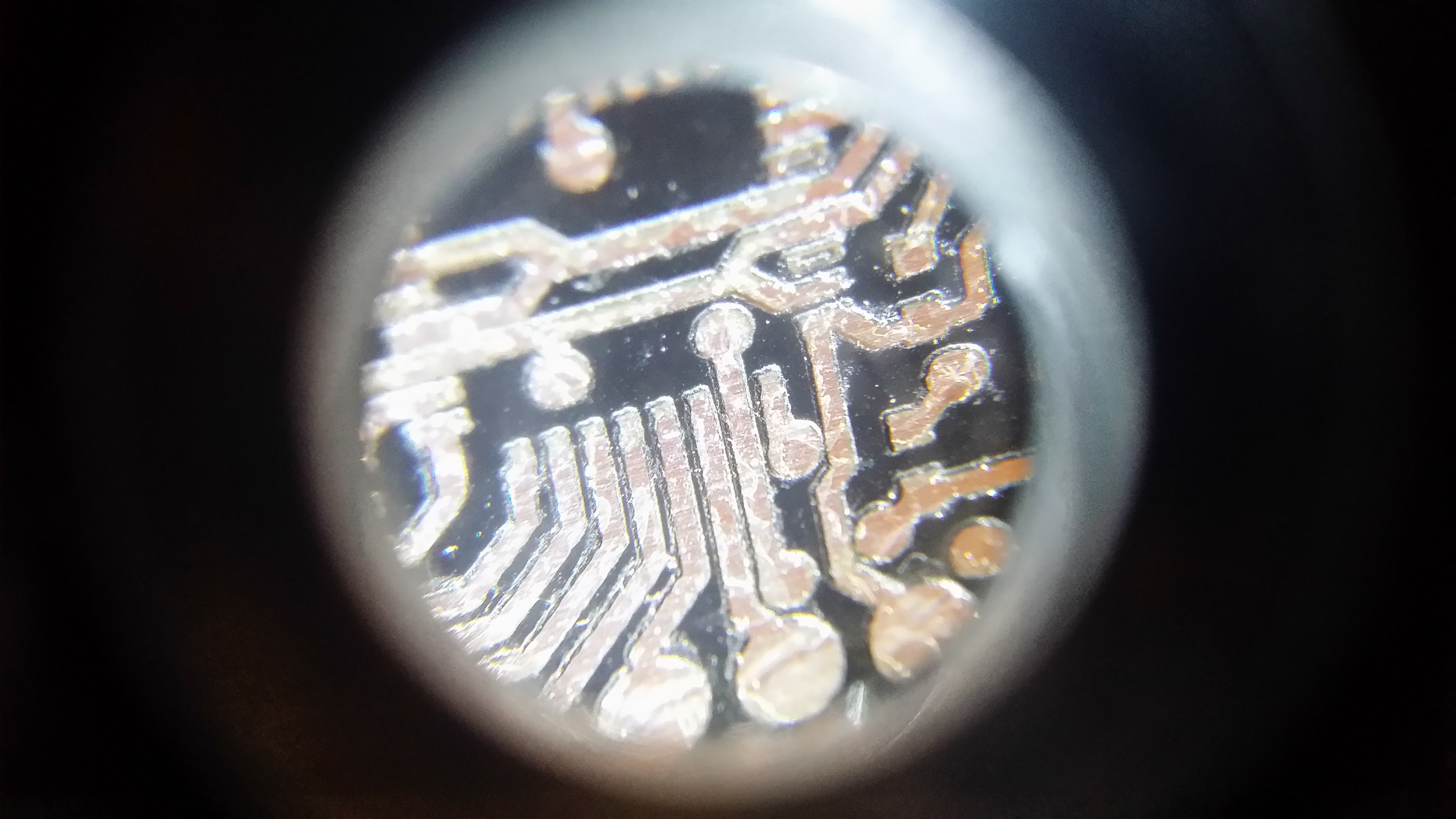

A little closer....

And there you go for now.. I've started the etching experiments... More on that later, but I am using a HCl + H2O2 mixture... It seems a little weak at a 2 part H2O2 and 1 part HCl... Straight HCl is too aggressive... so I'm trying to find a good balance... with the 2to1 ratio, it worked just a little slow. And keep in mind this will also be an automated process with the desktop etching machine I am designing... yay..

fl@C@

fl@C@

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.