Ah, Spring. In the spring a young man's fancy lightly turns to thoughts of...

Eeek! More than a third of the Hackaday prize time has passed! Have to make some progress real soon or curtail the project goals!

A status update follows.

The lathe at my hackerspace is still offline, so I haven't been able to do any more horn tuning. Next week 'fer sure.

I cast two new horns by way of a casting demo at the space - a 2nd horn for my small (50 Watt) transducer, and one for the large (100 Watt) transducer. I've got pics and intend to make a full blog post (two, actually) with instructions, tips and tricks, etc.

(ProTip: Don't run the kiln from an extension cord, at the hackerspace, as a casting demo. Kilns and extension cords don't mix. Now I know.)

After the [abortive] demo, one of the members offered me a piece of round-stock aluminum that's just the right diameter to make the bigger horn. That's about $30 of stock in one piece right there. Thanks, Adam!

And apropos of nothing, this is why I cast horns instead of, for example, ordering stock from McMaster Carr. I'm not Tony Stark.

(But to be fair, Stark himself cast his first arc reactor, so he too uses this method.)

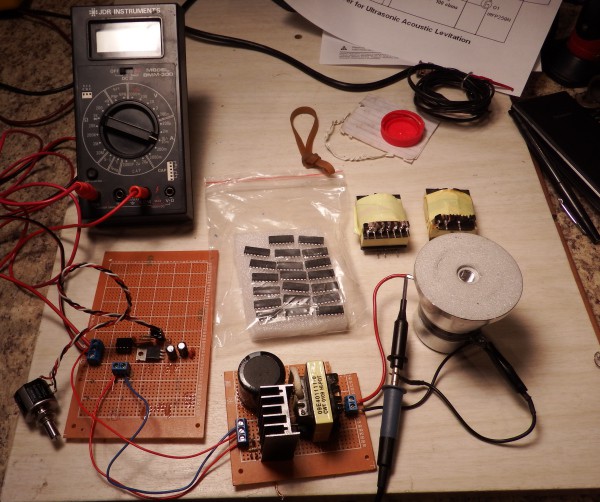

My frequency generator has poor resolution at 28KHz, so I made up a 555-timer squarewave generator (leftmost board) with a 10-turn pot. The pot sits in the middle of the frequency range of the transducer, so there's a lot of resolution with little drift.

I also breadboarded a SMPS transformer from a computer PSU and a drive transistor (lower-middle board). I also pulled two more transformers for comparison (upper right).

The good news is that the transformer generates 200 volts AC from a 12 volt supply!

This is about the right voltage to run 100 watt transducers off-resonance, which means that anyone who wants to make the circuit can get the only expensive-and-hard-to-find part from a junked computer.

It also means said hacker can run the circuit from a 10-amp 12-volt supply - in all likelihood an old computer PSU will suffice.

(I think. Time will tell if this is right.)

But this also means I can't show any progress. The 200 volts would push too much power through the transducer, so I have to get a PWM circuit running that will control power before I can show anything working. Right now I'm limiting power by crowbar'ing a supply that doesn't have overcurrent protection, and that's not an optimal solution.

THANK YOU

to everyone who signed up to follow the project & gave out skulls!

Getting the E-mail notices from followers/skulls makes me happy, and I save every one. (Not making that up.)

Peter Walsh

Peter Walsh

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.