-

Cartridge Design - Dispensing (Other)

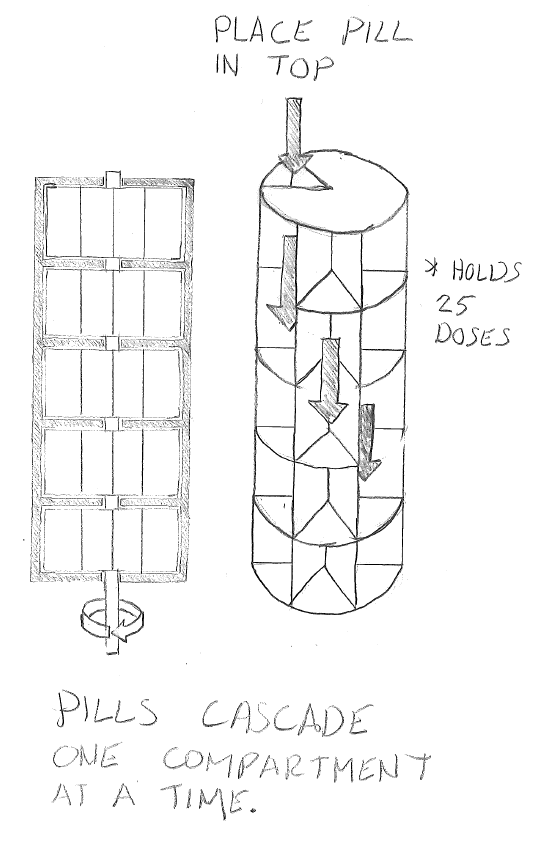

04/29/2015 at 19:17 • 2 commentsWe had a meeting last night, a decided we may have put the cart before the horse. Once we decided to go with the cartridge design, we just assumed it would have an internal "tube" holding the pills. We failed to look at alternative methods of packing/storing pills. Below are a few more pill dispenser ideas:

![]() The idea I'm most excited about is using a blister pack because it is already an acceptable packing mechanism in the industry. We could possible also handle the reel like an SMT reel. Some potential down sides include foil chunks being dispensed, large volume required to store reel, and used strip storage. Another idea we had was using thinner plastic to hold the pills, similar to string cheese (singles) packaging.

The idea I'm most excited about is using a blister pack because it is already an acceptable packing mechanism in the industry. We could possible also handle the reel like an SMT reel. Some potential down sides include foil chunks being dispensed, large volume required to store reel, and used strip storage. Another idea we had was using thinner plastic to hold the pills, similar to string cheese (singles) packaging. -

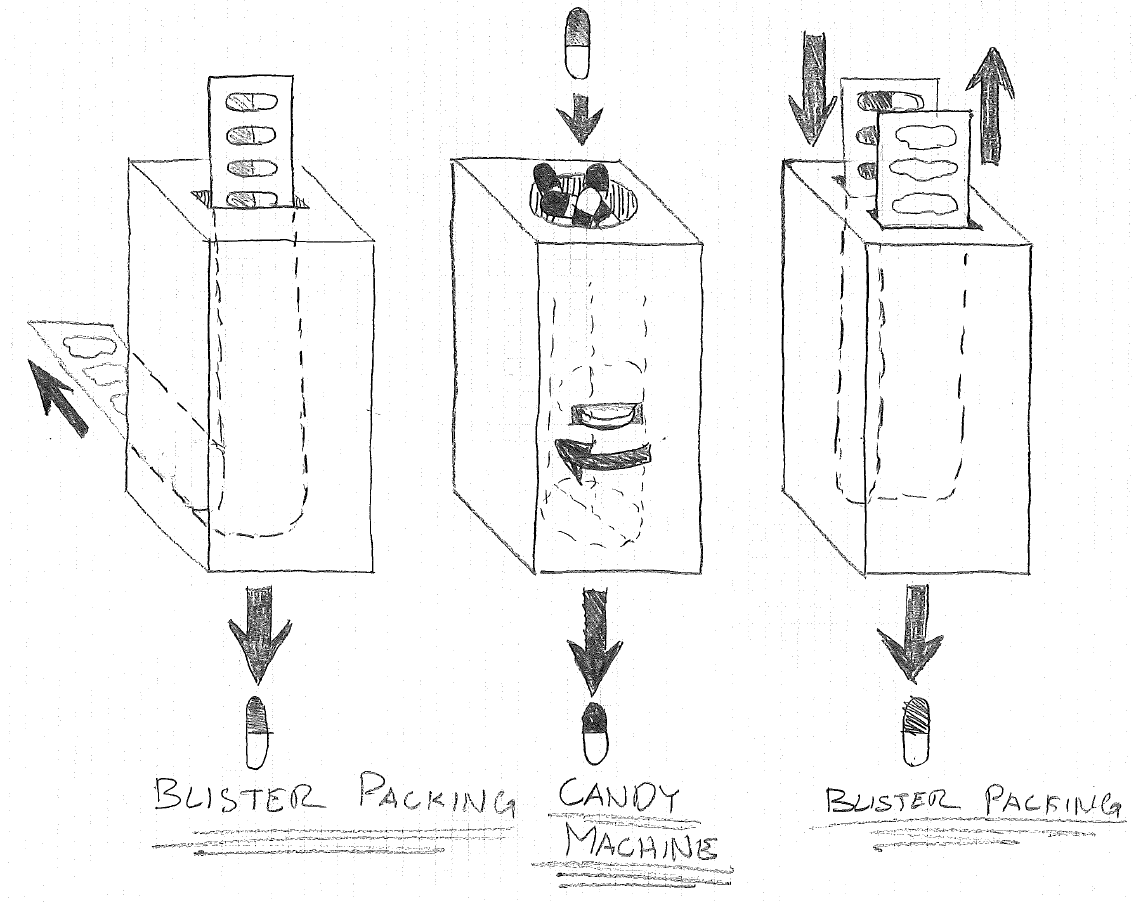

Cartridge Design - Dispensing

04/29/2015 at 18:29 • 0 commentsThe cartridge dispensing method is still up in the air. We brainstormed 3 ideas - plastic film with holes, a rotating drum, and a reciprocating plate. In each of these designs, the cartridge has a tube which holds the pills and a dispensing mechanism (except the motor, which is part of the machine). Below are the initial concept drawings:

![]()

-

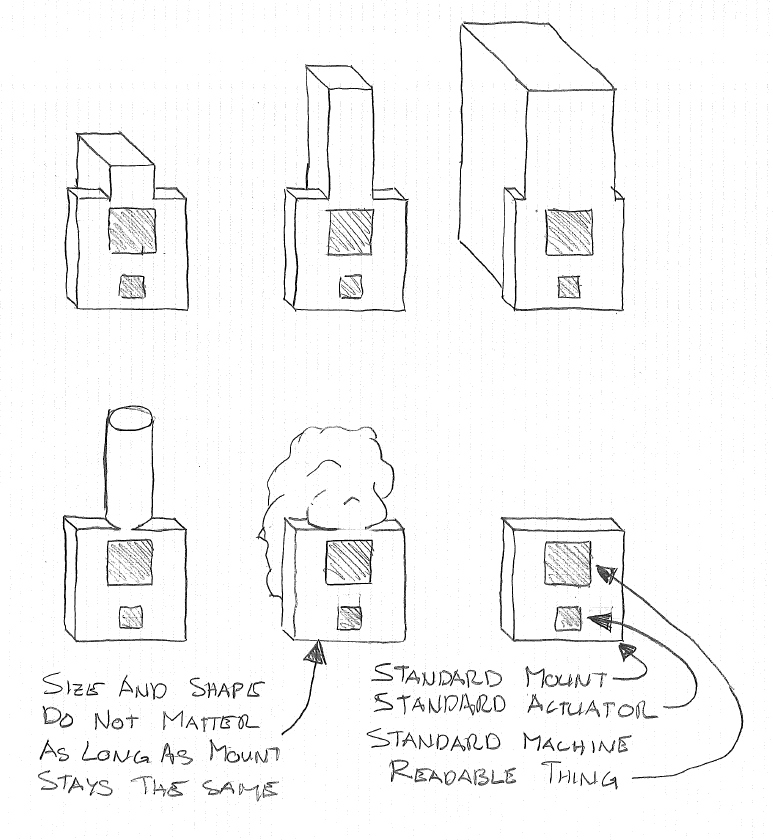

Cartridge Design - Cartridge to Appliance Interface

04/28/2015 at 22:28 • 0 commentsPills come in various sizes and shapes, and because of that, the cartridge template needs to be modular enough to accommodate different designs. We'd also like it to be flexible enough to accommodate ideas and designs we haven't though of yet. I'd ideally like the size and shape of the cartridge to be completely flexible (as long as it fits into the proper envelope). The only rigid part of the design would then be the mounting, actuation, and machine readable portions of the cartridge.

![]()

-

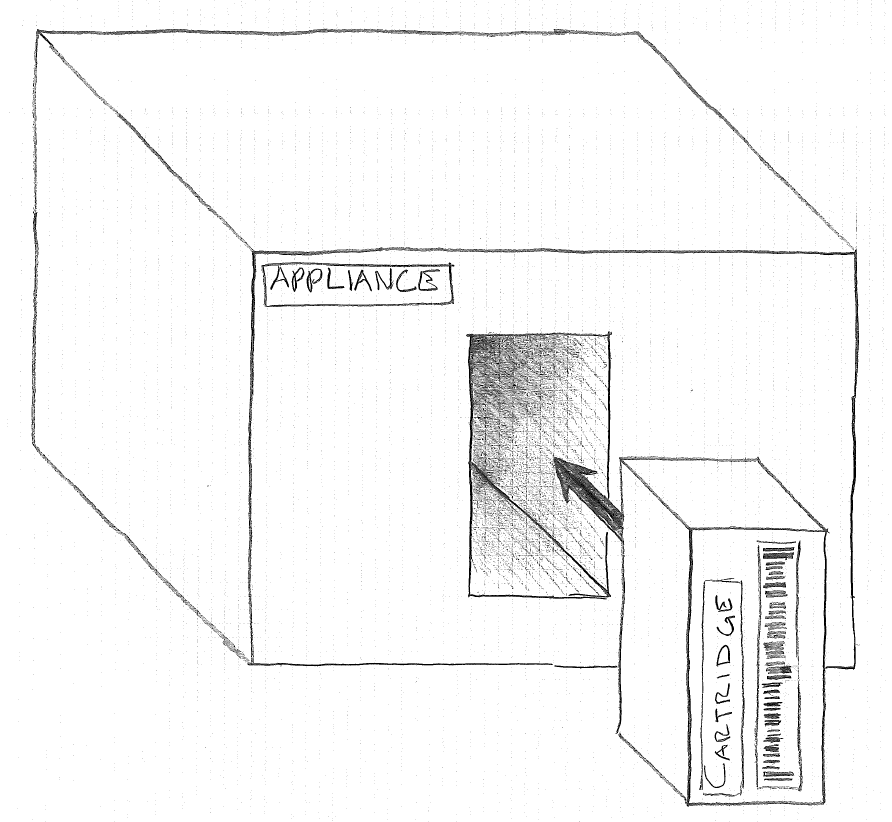

Cartridge Design - Overview

04/28/2015 at 21:53 • 0 commentsThe first step in designing our machine it to figure out a template for the cartridge. We need this so we can figure out the scale of the appliance. Design considerations are as follows:

- Cartridge should enter appliance from the front

- Cartridge should have a standard mounting design across all cartridges

- (Pill scale can vary between 1/8"x1/8"x1/16" and 1"x1/2"x1/2")

- Cartridges will have non-standard dimensions

- (Very small pills will not need as much room as very large pills, in general)

- Cartridge should require little dexterity to insert and remove

- (Use an ink cartridge as a meter - nothing requiring more dexterity)

- Cartridge should have a machine readable aspect

- (Unique ID, medication name, and/or dosage)

- Cartridge should have a standard actuation method

- (The same actuation method is used for very large and very small pills)

![]()

-

Project Direction - Resolved

04/15/2015 at 00:20 • 0 commentsAfter an in depth discussion, we've decided to go with the cartridge style (option 2) design. Although a cartridge system limits openness, we feel that it is ultimately a better direction.

Benefits of cartridge style:

- Eliminate many machine mechanisms

- Pill intake

- Pill sorting

- Eliminates the need to input (most) pill information

- Pill info can be linked to cartridge

- Dosing information can be linked to cartridge

- More consistent pill dispensing

- More open-ended packing options

- Cartridges can be upgraded or design after the fact

- Not constrained to pre-chosen pill sizes

- Not constrained to standard pill shapes

- Eliminate many machine mechanisms

-

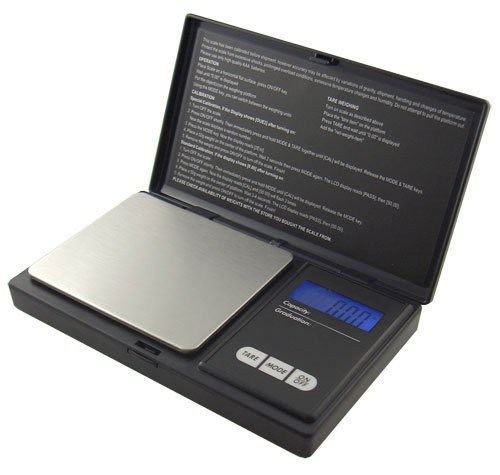

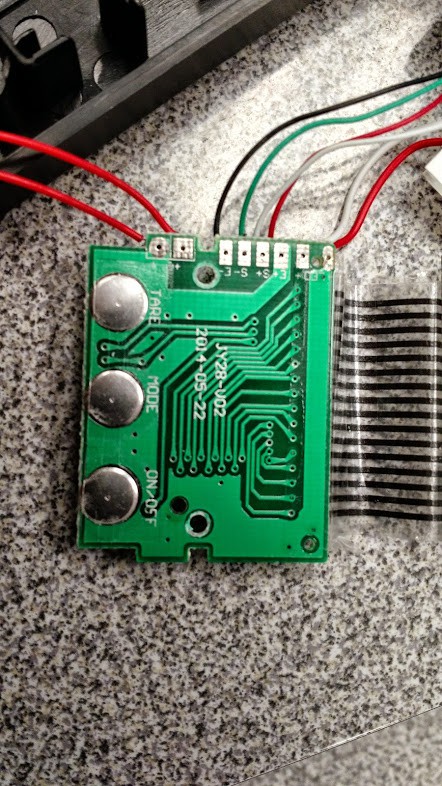

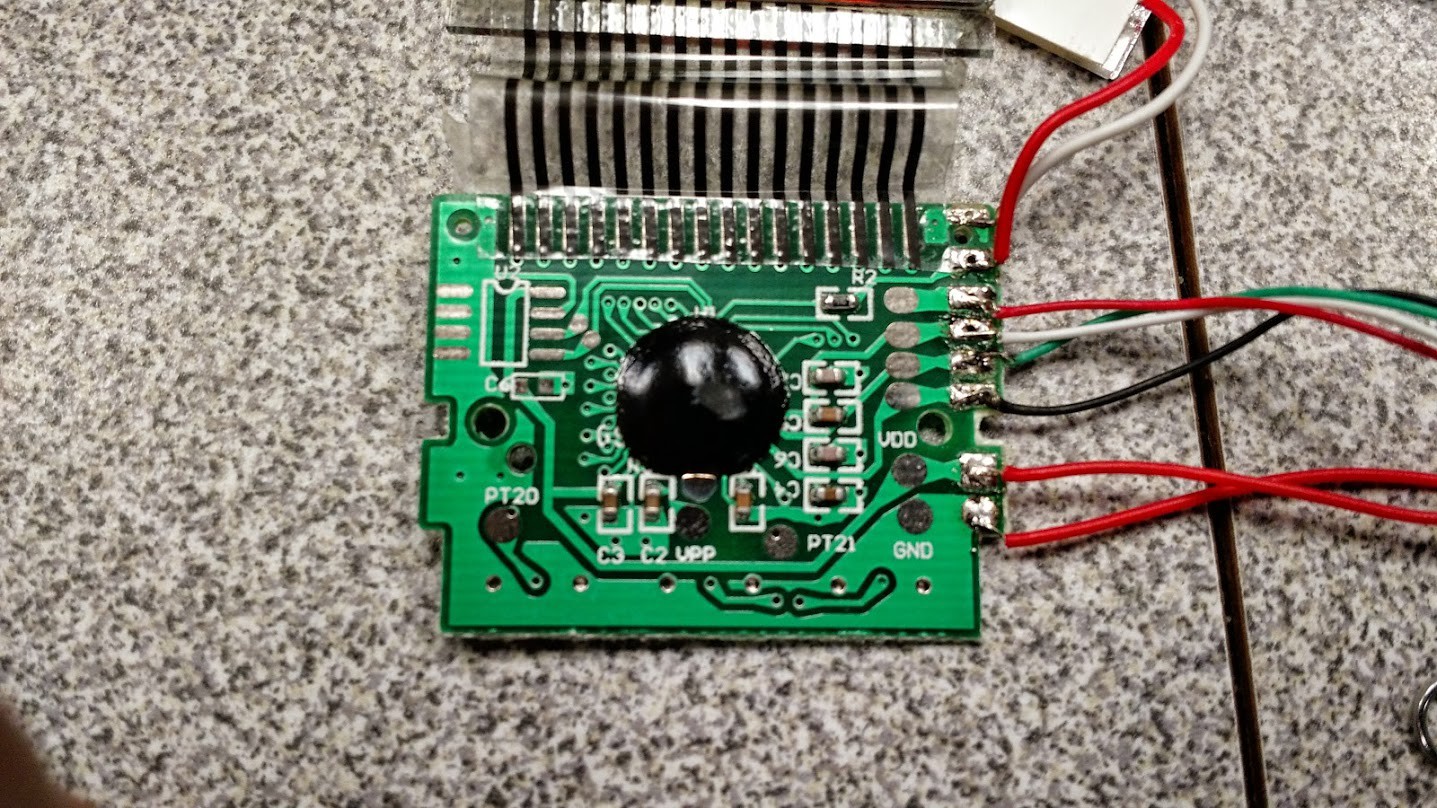

Scale

04/14/2015 at 22:04 • 0 commentsDmopalmer suggested we use a load cell or scale to verify pills. The AWS-100 was suggested as a cheap scale to hack. The scale was easy to tear apart (5 screws on top and some screws for the circuit board and load cell). The circuit board seems quite simple - 6 capacitors, a resistor and a microcontroller connected to a screen, led backlight, and load cell. Unfortunately the micro is covered with epoxy and i'm no reverse engineer.I'll have to make my own circuit to read the load cell, which is a chunk of aluminum with a strain gauge on each side. At college I scoffed when they taught us how to build a load cell - guess I was mistaken.

![]()

![]()

![]()

![]()

-

Project Direction - An appeal for input

04/06/2015 at 23:34 • 2 commentsI have a choice to make regarding the direction of the project, and I'd like to solicit feedback from the community. As I see it, my pill dispensing project can now go one of two ways:

- Universal solution (Accept most pills, from pill bottles - complex and possibly unreliable)

- Cartridge style (Only accept "Pill Minder" cartridges - simple, but possibly proprietary)

Currently, I'm only planning on making a few "finished" machines - one for my grandfather (who has Alzheimer's) and one or two for family friends. But, I want to make the best product I can make, which leads me to an interesting hypothetical.

Who is my target market, and what do I want to do with this machine? Do I want to partner with a large company like Walgreens and have my product only work with Walgreens branded cartridges? This would probably impact the largest number of people. Do I want a universal pill solution - as-seen-on-TV? My target demographic definitely overlaps with theirs. There are clear pros and cons of each choice. Please tell me what you think.

-

Concept - What to choose?

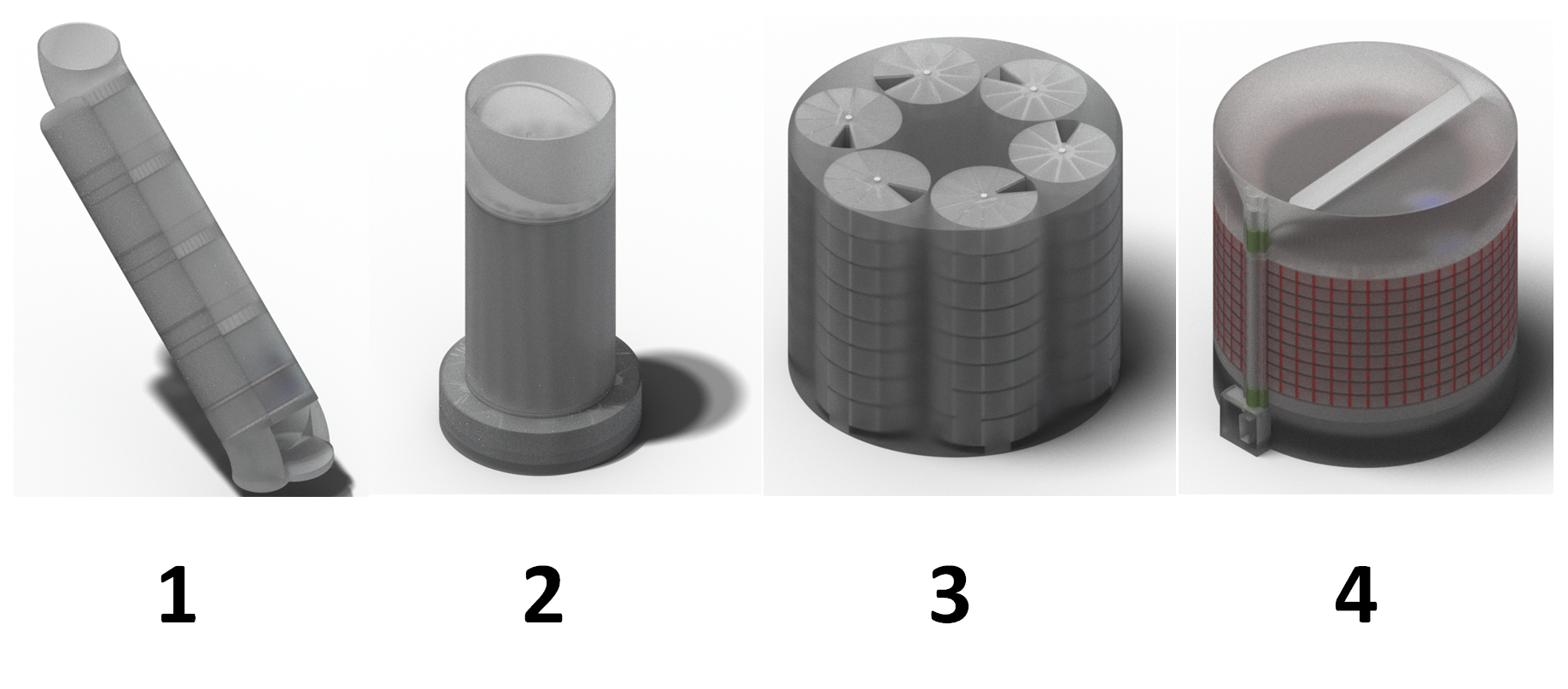

04/02/2015 at 19:24 • 5 commentsUp to this point, four virtual prototypes have been made.

- Rotating Plate

- Tube

- Cascading Container

- Stacked Container

![]()

I've learned a lot making these prototypes - more than I can possibly write about. Let my try to give a general outline of what the machine should do.

- Accept Pills

- Separate, catalog and verify if necessary

- With as much automation and as little required dexterity as possible

- Store Pills

- Pills can either be stored in an orderly manor or in bunches; in containers or tubes

- Dispense Pills

- Separate, verify if necessary

- Verify pills have been taken

- Easy to use/take pills

# 1 2 3 4 Name Rotating Plate Tube Cascading Container Stacked Container Accept Pills TBD,

Requires verificationTBD,

Does not require verificationTBD,

Requires verificationTBD,

Requires verificationStore Pills Stored in containers,

Not orderlyStored in tubes,

Tube must match pill type,

OrderlyStored in container,

OrderlyStored in container,

OrderlyDispense Pills Rotating plate,

Plates must match pill typeReciprocating plate (Probably),

Plate must match pill typeRotate storage mechanism Rotate storage mechanism Notes Simple but requires mechanism changes Simple but requires mechanism changes Complex Complex In working with these designs, I've (probably) narrowed it down to two choices: the tubes (#2) and the stacked containers (#4). I'm not sure I can properly explain the design decisions, but I believe these mechanisms represent the best choice for two competing strategies.

If we assume that people buy this device, bring it home, and use it with their existing medication, a stacked container (#4) is best. If we go with the ink-jet model where people buy "cartridges" from a pharmacy or online. the tube (#2) is best.

I envision the stacked containers (#4) to be quite complex, but versatile (able to accept pills from prescription bottles). Pills need to be separated, verified, and added to a container. Dosage data also needs to be imputed. Pills will then be dispensed and verified again.

Using concept #2 (the tubes) bypasses a lot of steps. Pills will be put in the tubes at the factory/pharmacy and verified. Placing a cartridge (tube) in the machine would be easy, and the dispense mechanism would be built into the individual tube (haven't figured that out yet, but I envision something similar to a pen or mechanical pencil). The dosage data could be pre-loaded onto the tube (NFC). The machine would only have to keep track of the tubes and activate the dispense mechanisms at the correct time - a considerably simpler process.

Now, the question remains - #2 or #4?

-

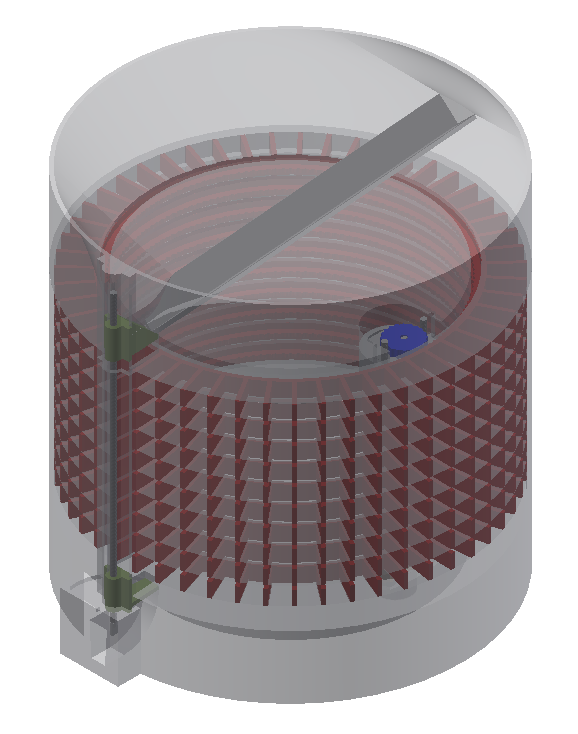

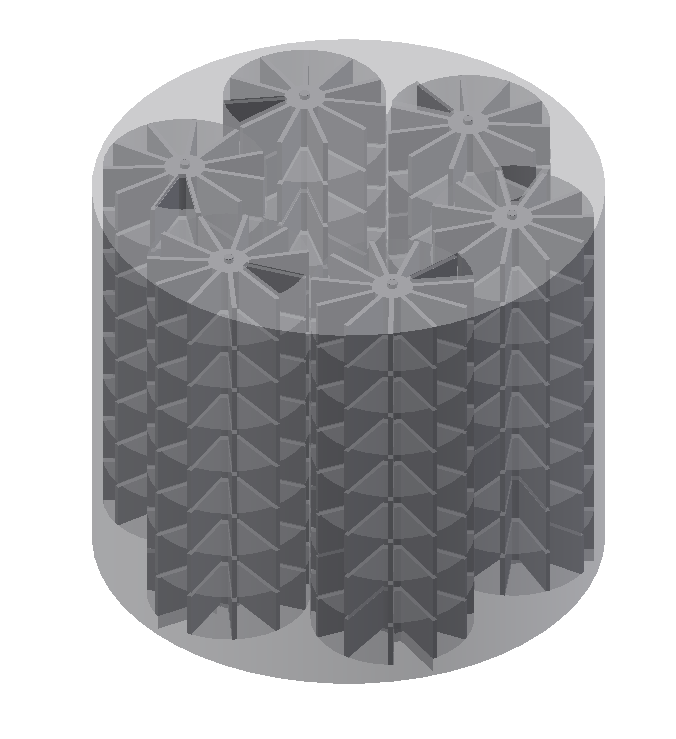

Concept - Containers (Stacked)

04/02/2015 at 16:23 • 0 commentsThe last log details a tall, skinny, cascading storage system. This concept is a fat, short system that does not cascade. Each pill type is stored on a different level (in a veined carousel), with a shared shaft to add/remove pills. Unfortunately, this adds complexity, with a "shuttle" to access different levels (for adding pills) and possibly a second shuttle to rotate individual levels.

I was also toying with the idea of a shake conveyor, in this case vibrating a piece of sloped angle aluminum. Below are some renderings.

![]()

![]()

If I can control the orientation of the pills, I can make the containers more efficient. In this case, I made them about 1"x0.5"x0.5". In a 12" cube I'm fitting 500 containers. I was also experimenting with an idea to get the pill delivery shuttle out of the shaft at it's lowest position.

Pros:

- (Hopefully) easy to load

- High density storage

- Somewhat universal system (no changing parts)

Cons:

- Complex (with tight mechanical tolerances)

- Loading pills and dispensing will be slow

Things that aren't quite figured out yet:

- Loading

- Sensor locations

-

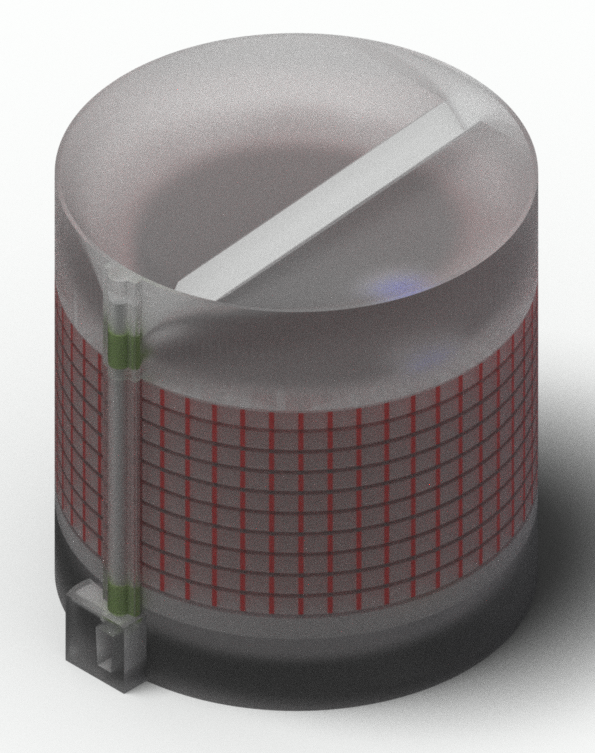

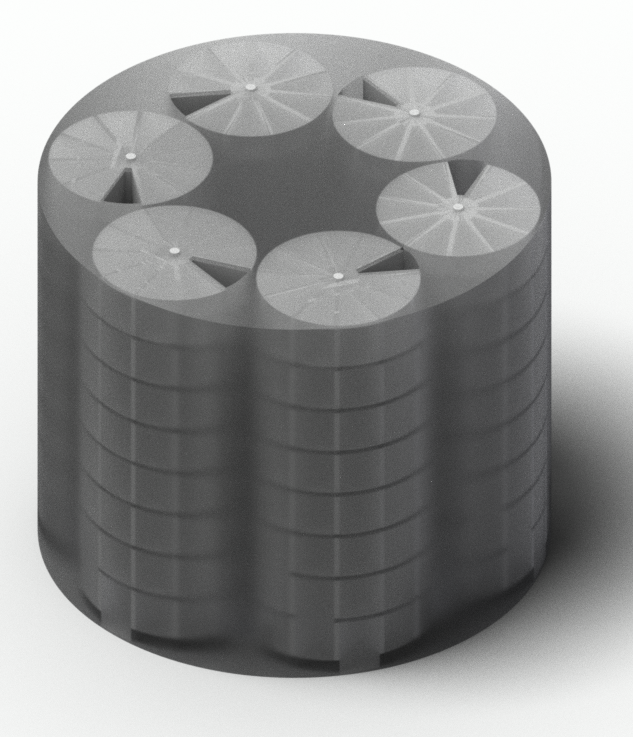

Concept - Containers (Cascading)

04/02/2015 at 16:00 • 0 commentsThis concept departs from the "store pills and dispense them one at a time" theme. Instead, doses (one or more pills) are held in individual containers. By making a rotating carousel of fins, and clever top/bottom plates, a high-density cascading system can be created.

![]()

Unfortunately, the system can only be indexed one way, so if the system is filled half way (and then dispenses) the system will have to empty it's entire inventory before more pills can be added (or else there will be a pill gap).

To facilitate multiple pill types, more systems will have to be added (possibly in a carousal). Below are some renderings of what that would look like.

![]()

![]()

Pros:

- High density storage

- Easy to dispense

Cons:

- Possibly hard to clean

- Hard to combine multiple systems

Things that aren't quite figured out yet:

- Combining multiple systems

- Loading

- Dispensing efficiently

- Adding a collection spot

Pill Minder - Automatic Pill Dispenser

Automatic pill dispenser for the aging and forgetful

dthunes

dthunes The idea I'm most excited about is using a blister pack because it is already an acceptable packing mechanism in the industry. We could possible also handle the reel like an SMT reel. Some potential down sides include foil chunks being dispensed, large volume required to store reel, and used strip storage. Another idea we had was using thinner plastic to hold the pills, similar to string cheese (singles) packaging.

The idea I'm most excited about is using a blister pack because it is already an acceptable packing mechanism in the industry. We could possible also handle the reel like an SMT reel. Some potential down sides include foil chunks being dispensed, large volume required to store reel, and used strip storage. Another idea we had was using thinner plastic to hold the pills, similar to string cheese (singles) packaging.