One of the first challenges facing someone who wants to use SMD components is their size which ranges from small to subatomic, to make them easier to handle and allow machine placement passive SMD components are almost always supplied on tape. SMD components on tape sit in a little pocket with a clear cover tape to keep them in place.

Having loose tape floating around the bench is a recipe for frustration, because they've been cut off a spool they wont lay flat and they're dying to swipe across your carefully populated board and ruin your hard work.

My first solution to this problem was to stick the tape down to a scrap of wood with double sided tape, it's easy, it's effective and it's cheap.

Once I started making bigger batches the shortcomings of the Wood-n-Tape technique became apparent, you can only stick down so much tape so I would run out of certain values and surprisingly, picking from a different location each time slows things down more than you'd think.

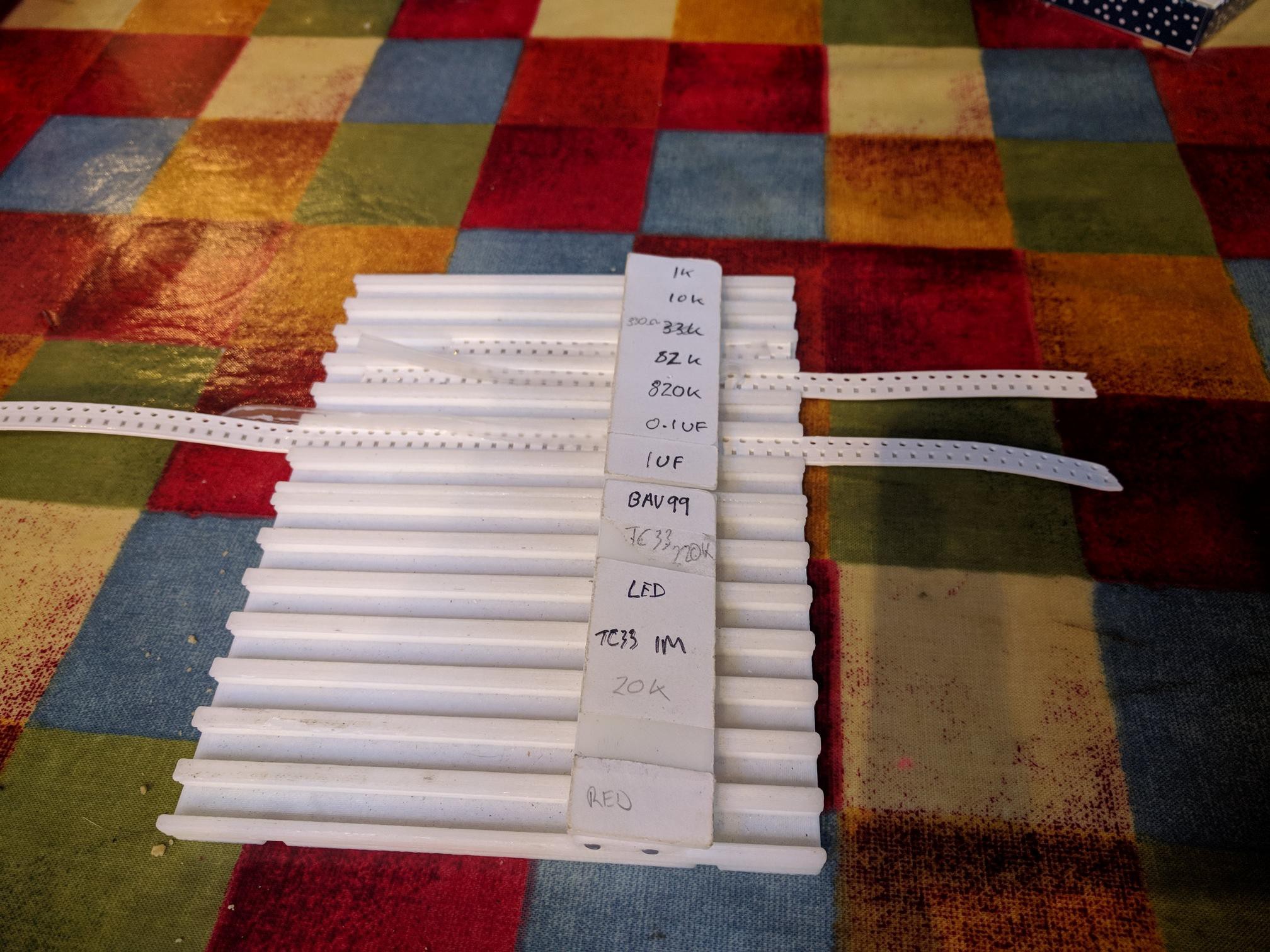

My first attempt to engineer a tape holder/ component feeder consisted of slots for the tape and somewhere to label what's what. What can't be seen very well in the picture is that the cover tape can be threaded underneath the labels around a shaft so that when the cover tape is pulled back it advanced the tape and exposes the components one at a time, in the same place, for picking.

Idris

Idris

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.