I used the flat tape feeder shown in the last log for a couple of months, it was an order of magnitude better than sticking tape to a piece of wood but still it had plenty of drawbacks.

- Longer component tapes still flapped about all over the place.

- Spent tape would encroach on the work area

- Batch sizes kept getting bigger and I would again run out of certain components.

- Ergonomically, assembling components flat on a bench is pretty uncomfortable.

About this time it was becoming obvious that there was a reasonable market for our product and it would be worthwhile investing some time and money to streamline the production process as much as possible.

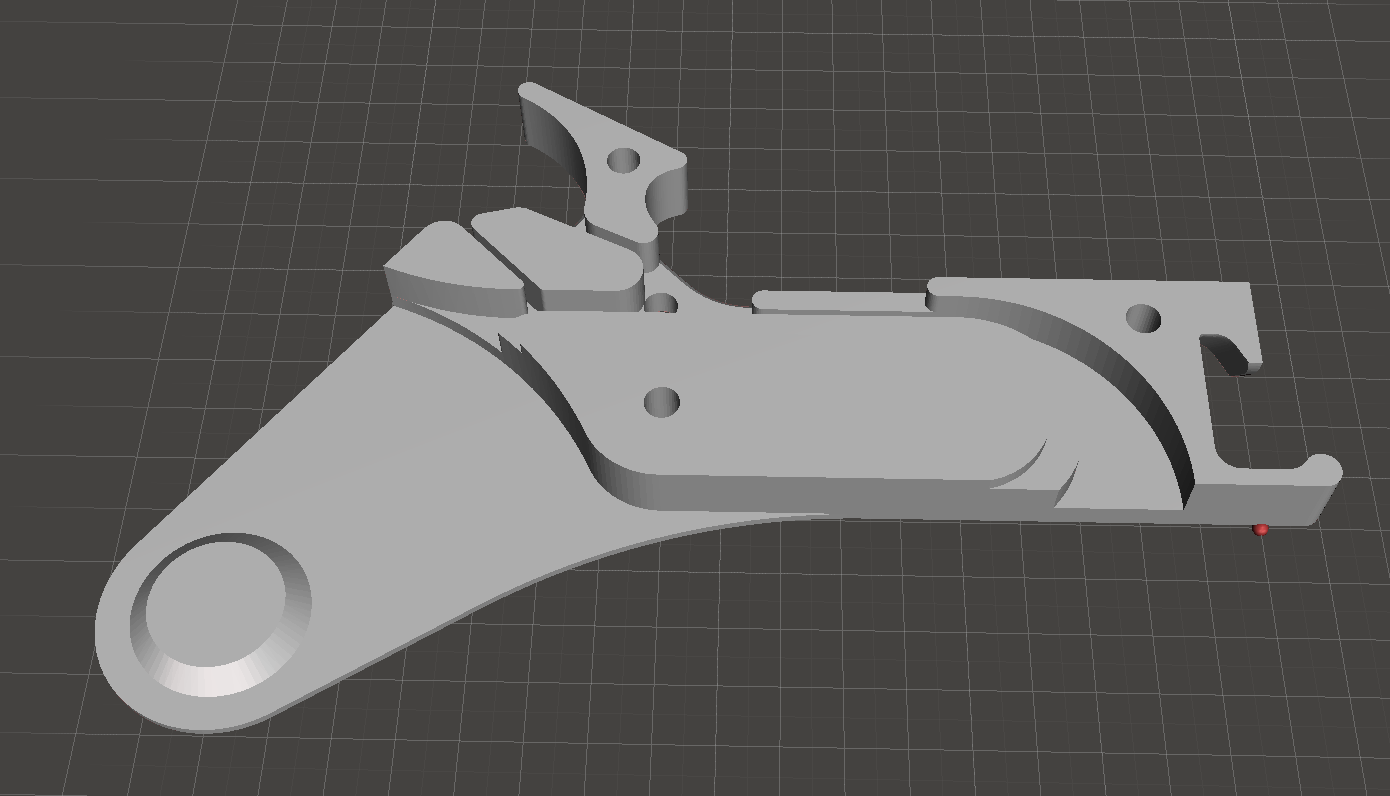

This is the result of many iterations and a couple of months of development, sometimes you need to work with something for a while to really get to understand what's good and what needs improving.

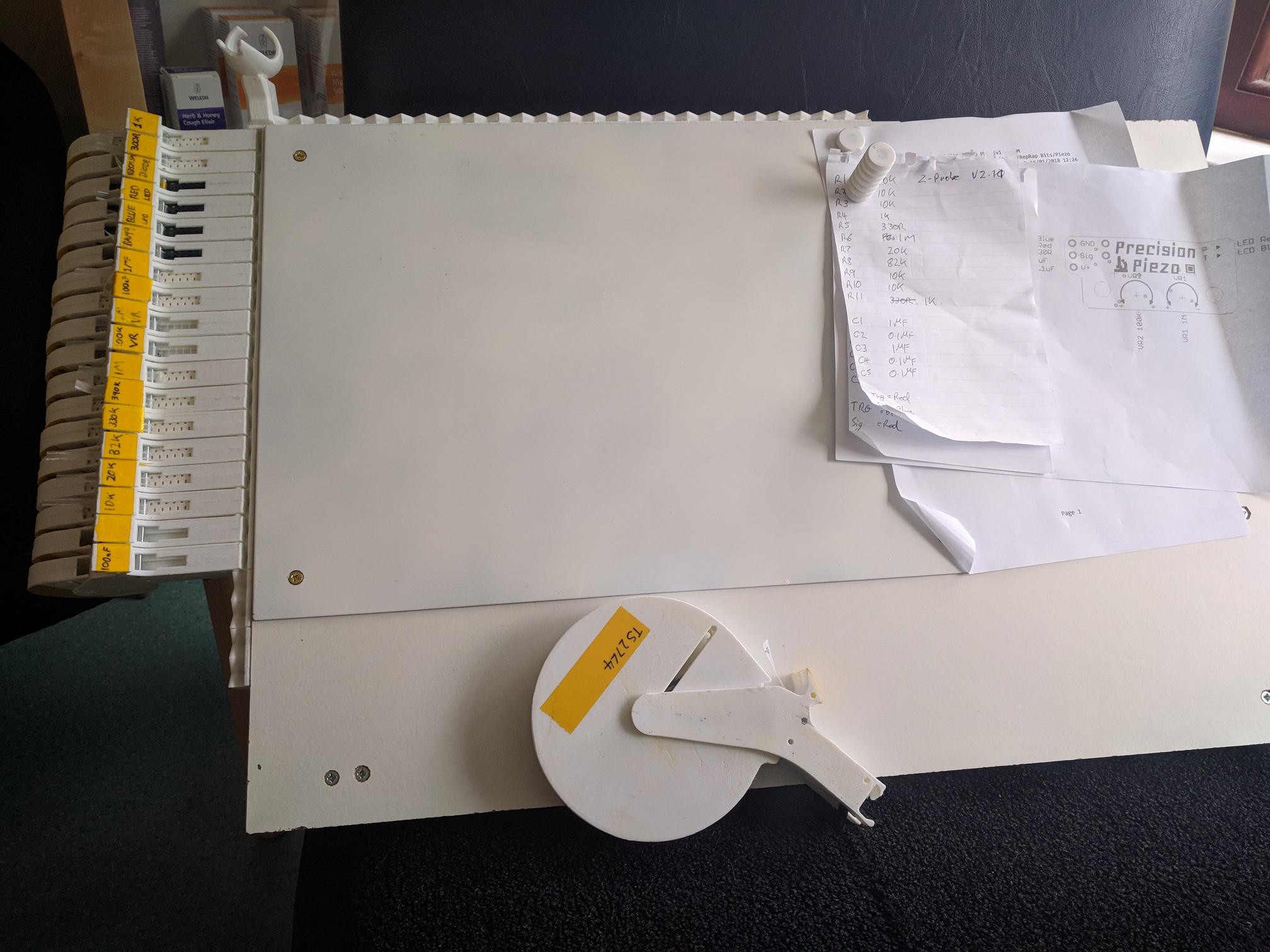

I use these feeders in a number of sizes, a small 8mm tape feeder on the left and a larger 16mm feeder on the right. The 8mm feeder will hold about 2M of paper tape or roughly 500 components. I've never filled the larger feeder to capacity but it will probably hold many hundreds of parts. The spools are removable to allow refilling and potentially swapping of components though currently I use one feeder per component value.

The feeders clip onto the side of an assembly board which then clips to the front of my bench, this makes assembly much more comfortable. Mounting clips along the side and top allow the feeders to be clipped wherever it's convenient. A steel sheet on the front of the board allows magnets to be used to hold PCB panels for assembly and at the top left of the board is a holster for my vacuum pick up pen.

Idris

Idris

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.