-

Transformer from Washing Machine

12/04/2016 at 22:54 • 0 comments[A Hackaday article submitted for the "we're hiring" article.]

FAIL!

After writing the article, it doesn't meet the "at least 150 words" requirement, and I don't see a good way to add more text. I could change the scope from this specific project to transformers in general, I suppose.

Finding a good project to report on is HARD!

![]()

December 4, 2016 by Peter Walsh

In the zombie apocalypse, if you need a transformer and all you have is an old washing machine, we've got you covered.

[electricretrotech] First removed the induction motor from an old washing machine and unwound the coils, resulting in a bare iron core and several heaps of wire. He then rewound the core into a transformer configuration using some of the wire removed in the first step.

The result is a rather useable transformer that looks like it could be used as an ad-hoc spot welder. Assuming the windings don't exceed the maximum flux density of the iron core, the resulting transformer would even be reasonably efficient.

If you want to try winding your own transformers, check out Practical Transformer Winding for some step-by-step instructions.

Continue reading

-

Ground-based delivery drone probably won't get stolen

12/04/2016 at 22:04 • 0 comments[A Hackaday article submitted for the "we're hiring" article.]

FAIL!

After some composition work, it looked too much like a press release and didn't fit in with the "look and feel" of Hackaday, so I scrapped it in search of a better project. (Note: Text below is unfinished.)

![]()

December 4, 2016 by Peter Walsh

Drone delivery is the next big thing in robotics, especially for "last mile" delivery. Amazon, for example, is developing an airborne drone delivery system to deliver goods directly from a nearby distribution center or truck.

Starship Robots, a ground-based drone delivery system that can carry two shopping bags worth of goods, has completed preliminary testing in a handful of cities in Europe, and will begin testing in American cities sometime this fall.

Ground-based has a lot of advantages over drone-based: it's safer for the public, can carry heavier and bulkier items, and requires less energy than airborne delivery. The robots are semi-autonomous and can can make simple decisions on their own to avoid collisions and navigate around obstacles (such as pets). The device can also call for a human remote operator when it encounters situations it can't handle.

The...

Starchip robots have traveled close to 5,000 miles and encountered over 400,000 people without a single accident. It claimed that during testing, about two-thirds of people ignored the bots entirely, while the rest reacted to them mostly favorably, often by snapping photos. (Note: Clipped from other article, used as "notes" to inform my own writing.)

Check out the video below the break to see the drones in action.

Continue reading

-

Optical flow sensor from an LED mouse

11/22/2016 at 02:15 • 4 comments(A response to a question on the blog.)

Here's an example of working with an optical flow sensor.

Take an LED mouse and clip out the DIP micro using a pair of side cutters, then install headers into the footprint. You can then attach jumpers to PWR, GND, and the two SPI lines as needed.

![]()

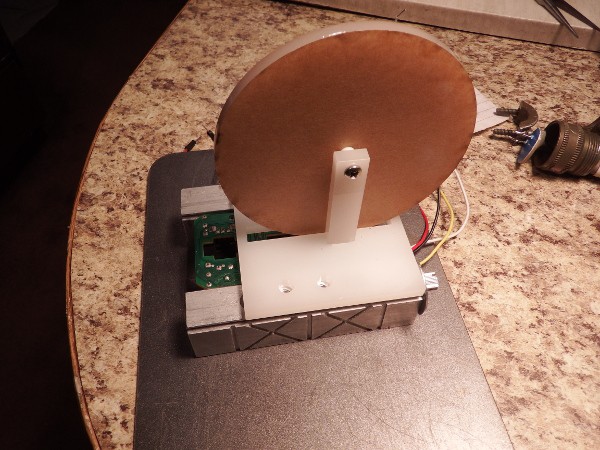

And here's my homemade dev kit. The mouse board is under the "ferris wheel", which was cut from a laser. Turn the wheel by hand and watch the measurements flow by on the serial port.

(Using an arduino program to read the flow sensor.)

![]()

I'd give out the arduino code, but it's a bare-metal program (ie - not a sketch). Not for the faint of heart.

If there's a ton of interest I'll put the code up somewhere.

-

Laser spot size at our hackerspace

04/11/2016 at 18:54 • 0 commentsAn image for a post on the HAD blog.

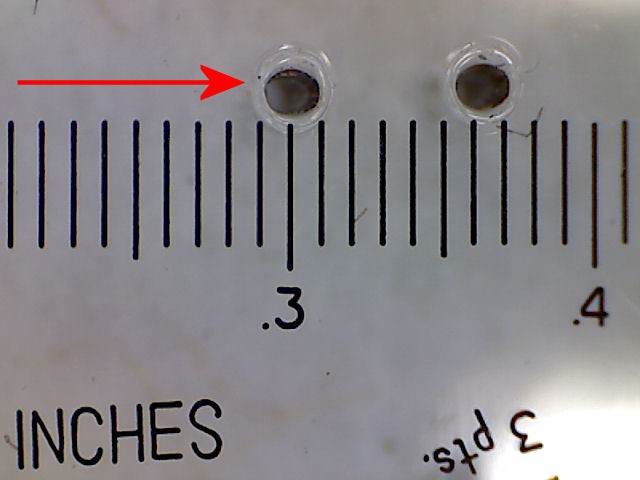

The transparent graticle on my microscope easily shows the spot size of the laser at my hackerspace. I conclude from this that the "kerf" of our laser is about 0.02 inches (20 thou).

Using a micrometer and some precision-ground rods, a 6mm hole measures out as 6.052mm. Considering 0.02 inches as 0.508mm, 90% of the kerf is inside the hole and 10% is outside.

![]()

-

Need help from NH business

03/06/2016 at 05:20 • 0 comments

My hackerspace, Makeit Labs, was awarded $250,000 in tax credits to help move and renovate. We must sell these credits before the end of the month, or we lose them!![]()

We're looking for NH businesses to purchase the credits by making a donation to us and reducing their own taxes.

Under the credit program, a typical business donating $10,000 would save $9,000 on their state and federal taxes! That $10,000 donation would cost them only $1006!

New Hampshire provides a handy calculator that shows what your results would be for your donated amount.

Donors complete a pledge form by March 31, and make the purchase by June 30. (Contact us.)

If you work for a NH company, please ask them to consider pledging to purchase some of our tax credits!

MakeitLabs has a lot of really smart people. We frequently help out by answering questions and giving assistance to members and other people who drop by. We helped one company so much that they bought us a laser cutter, and we recently helped a local business owner avoid an $8,000 repair bill.![]()

We're setting up a tech incubator for businesses to come and use our facilities. If your company does engineering development or experiments, or just wants access to a 3-d printer or laser cutter (and many other tools), consider getting a membership for one of your employees.

Open house every Thursday from 6:30pm to 9:00pm in Nashua, NH (map).

-

Weston cell teardown

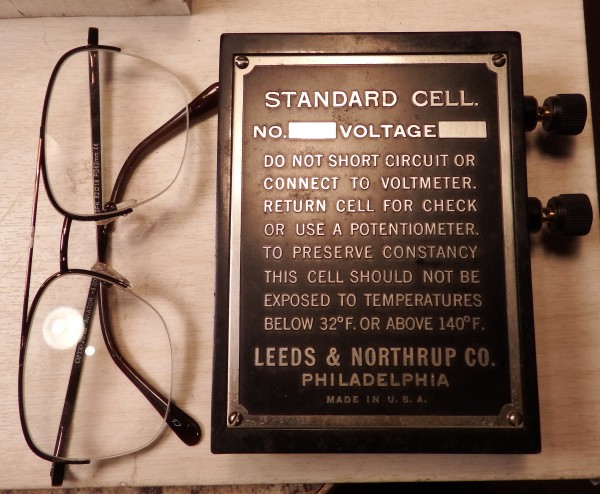

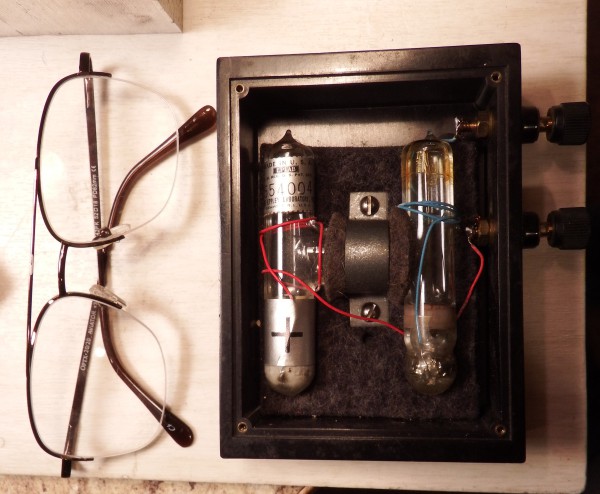

09/22/2015 at 21:14 • 0 commentsThe insides and outsides of a Weston cell I bought at an antique store.

![]()

![]()

-

Laser Internferometry discussion

07/24/2015 at 19:27 • 24 commentsThis is for people who want to discuss laser interferometry.

I've a physics guy, and I've got some hands-on experience interferometers, other people have experience in CNC machine mechanics, so I set up this area for people do discuss ideas and ask questions.

-

Ball And Socket

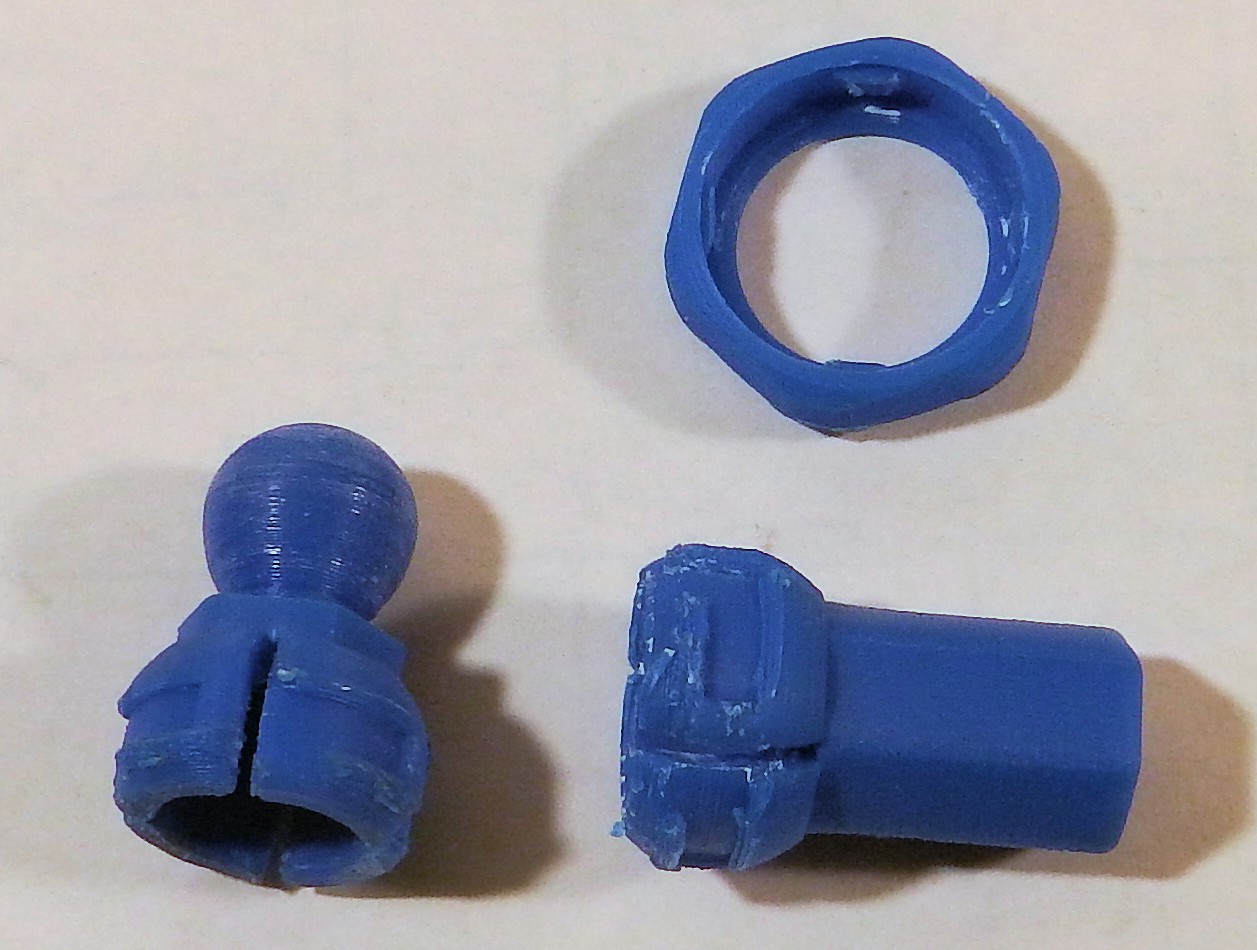

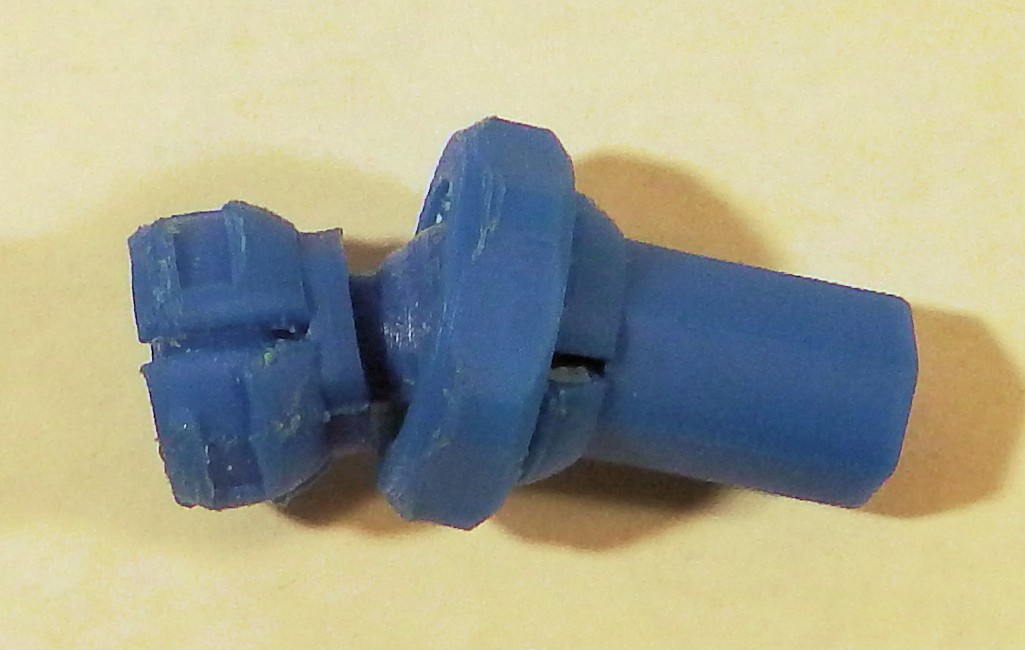

05/23/2015 at 17:27 • 0 comments![]()

![]()

-

Fixing a Floor Mat

05/14/2015 at 03:33 • 0 commentsSummary

This is not really a hack, it's just... an odd use of the laser cutter.

1) You can cut carpet on a laser cutter

2) Use the flame-test to determine if the material is cuttable

3) Cutting carpet actually works quite well

4) Carpet seaming tape is awesome

5) I can drive for another couple of years before replacing the carpet.

You might also like my other project.

The problem

The carpet under the accelerator in my vehicle wears out every couple of years.

Replacements never fit properly, and I *hate* them. "Fits all model trucks" really means "lots of wrinkles, and slides around because the grommet holes don't match the floor cleats".

Looking at the problem got me thinking: "I wonder if the laser cutter will handle carpet?"

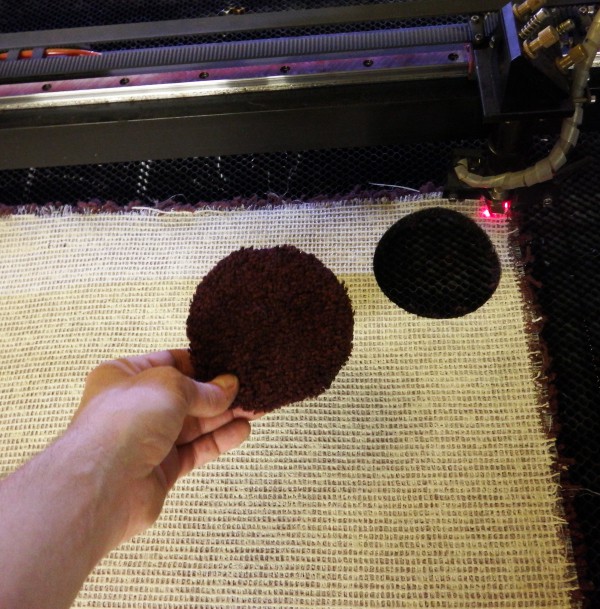

![]()

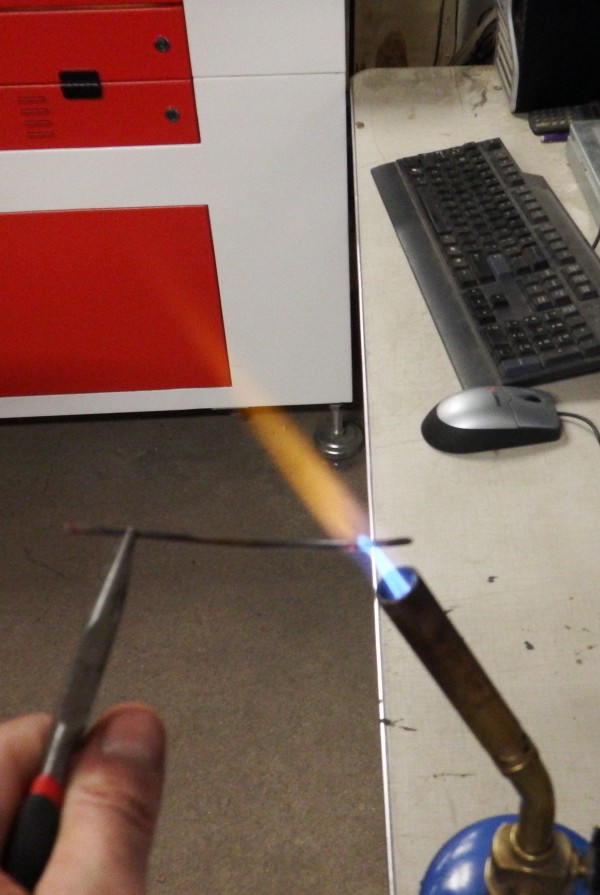

The Flame Test

The first question to ask is whether the material can be cut in the laser. To find out, we perform a flame test.

Laser cutting chlorine based materials will release hydrochloric gas (HCL), which is highly corrosive and will eat away at the mirror surfaces and other hardware, especially aluminum. This is not an exaggeration: the gas is *very* aggressive, and cutting chlorine-based materials such as PVC is one of the things that will get you walked out of my hackerspace.

We keep a torch, lighter, and bits of copper wire next to the laser, just so people won't have an excuse for not doing the test.

First, heat a copper wire to red hot.

![]()

Next, touch the hot wire to the material to be cut.

![]()

Place the wire back into the flame and note any color changes. Yellow is normal, green indicates the presence of chlorine.

(The hot wire picks up bits of molten material, and chlorine in the material will form copper chloride which glows green in the flame. Yellow indicates sodium, which is pretty-much everywhere.)

![]()

So far, so good: the original mat is OK to cut. Check the replacement carpet as well.

![]()

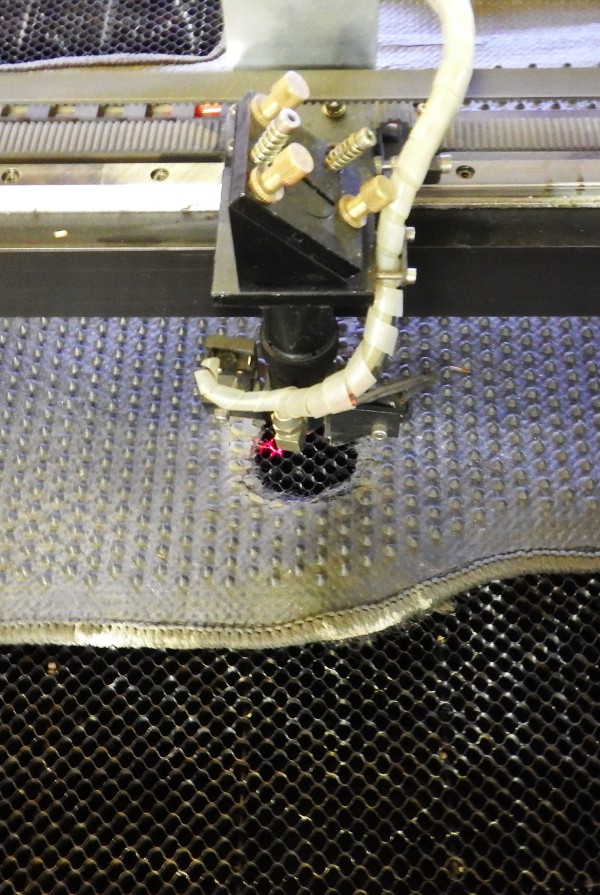

Cutting the patch

With both carpets testing OK to cut (including the rubbery backing), line up the floor mat and excise a circular section.

I'm using 65% power at 12mm/sec and 2 passes on our 80 Watt laser (your settings will be different).

![]()

![]()

Without changing the dimensions, excise a similar plug from the replacement carpet:

![]()

Carpet seaming tape

The term "carpet tape" refers to double-sided tape meant to keep carpets from sliding around. I'm using "seaming" tape, which is single-sided and meant to glue two abutting pieces together.

Also, there's hot and cold seaming tape. Hot tape requires a special heater to melt the glue into the weave of the backing, I'm using the "cold" type, available at Lowes, Home Depot, and many other places.

![]()

Peel off the back and apply. This stuff is VERY sticky... something to note for future projects.

![]()

Final installation

Step on the plug a couple of times to work the tape adhesive into the backing, and reinstall in the vehicle.

![]()

And there you have it: good for another couple of years.

![]()

Discussion

This was so easy it leads me to think of artistic uses for the technique.

For example, given two colors of carpet tile, you could cut patterns and swap the colors so that each tile contains a custom pattern.

It shouldn't be too hard to make a carpet version of an M.C. Escher pattern, for instance. Angels and devils, black geese flying against white geese, and so on.

I'd be interested to hear of any hacker/artist that does this. Let me know...

-

R7 looks correct

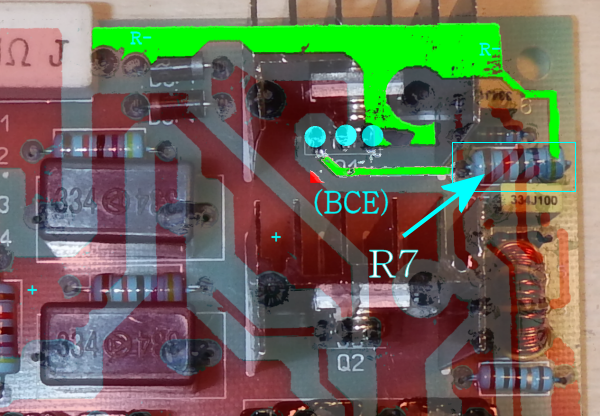

04/15/2015 at 23:10 • 0 commentsR7 appears to connect B-E in the transistor, as shown:

![]()

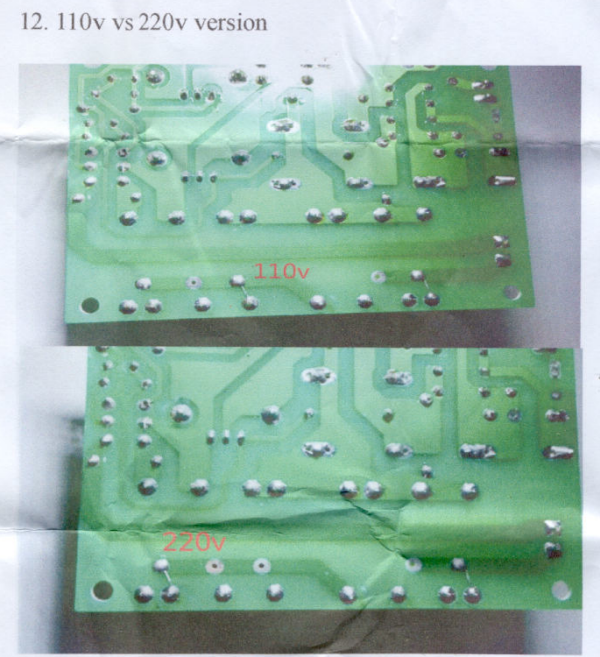

The instructions sheet that came with the supply have this section:

![]()

Peter Walsh

Peter Walsh