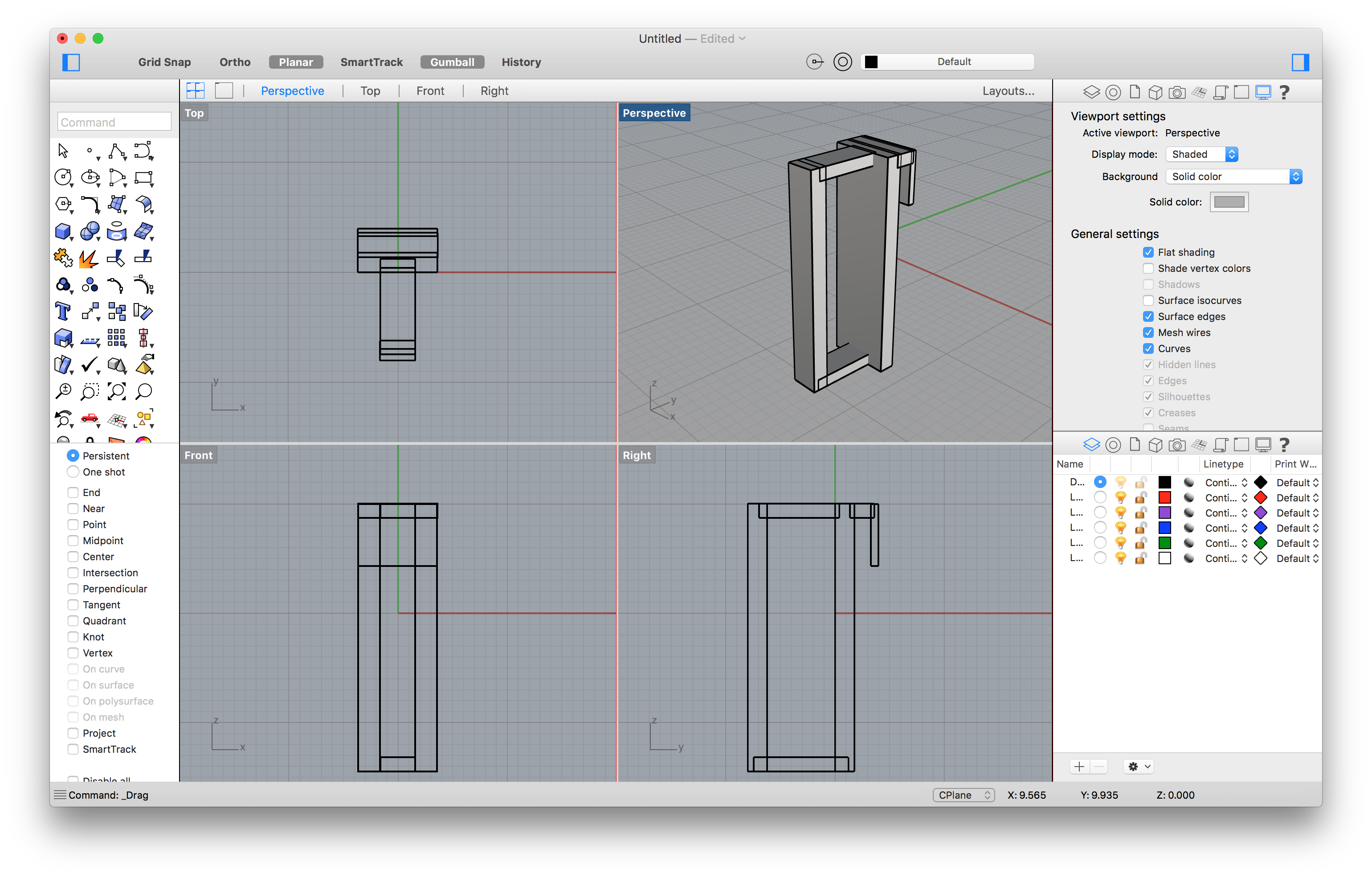

My program of choice for doing the technical work is Rhino, since I know the program well, find the interface to be more intuitive than Blender and can locate bad meshes much easier should a problem arise. My first two drafts were not to scale, and were to do quick mockups of each handle type. Ultimately to use gravity to my advantage and to minimize the need for screws or additional adhesives, I decided to go with the top hook handle.

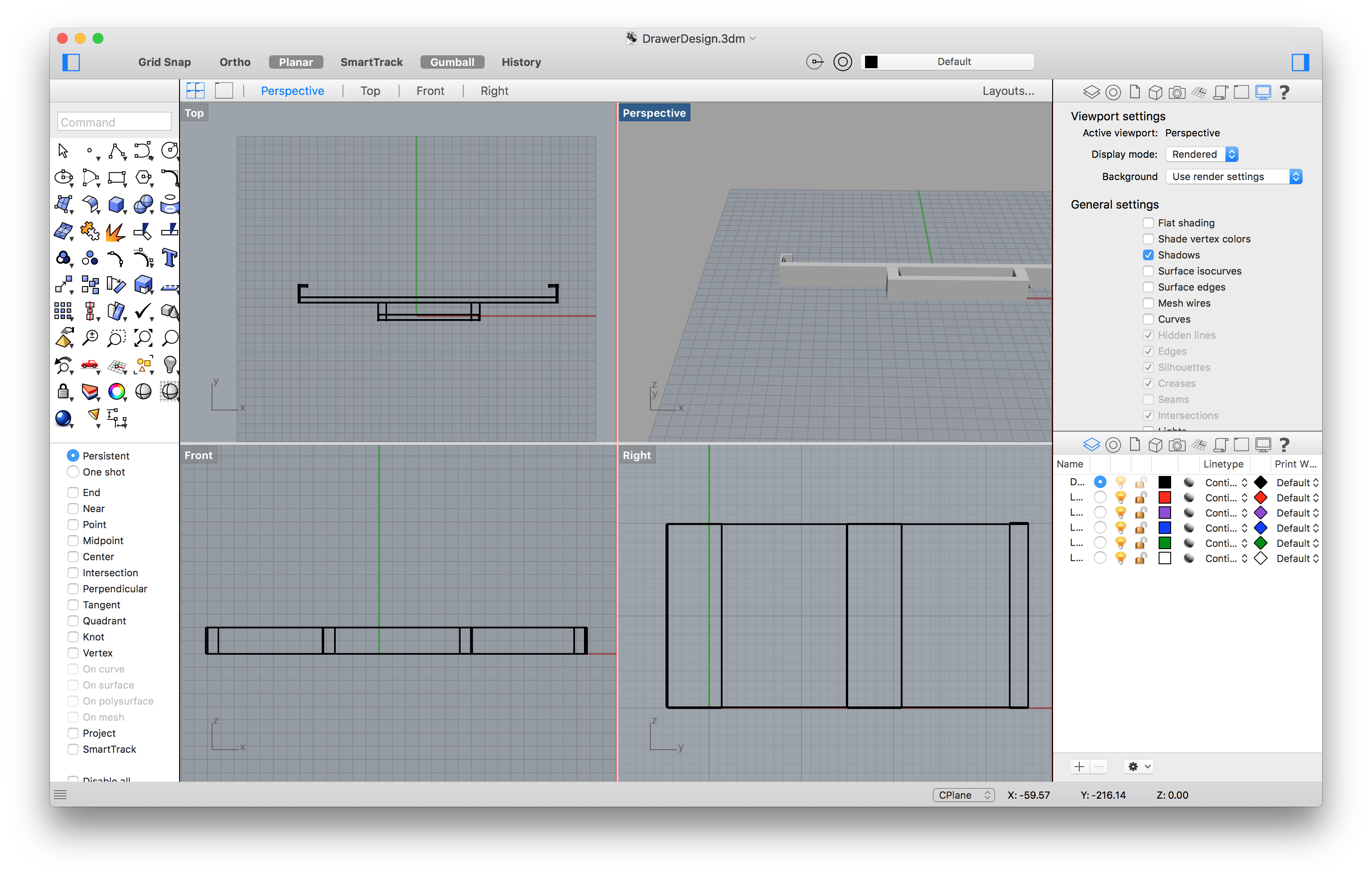

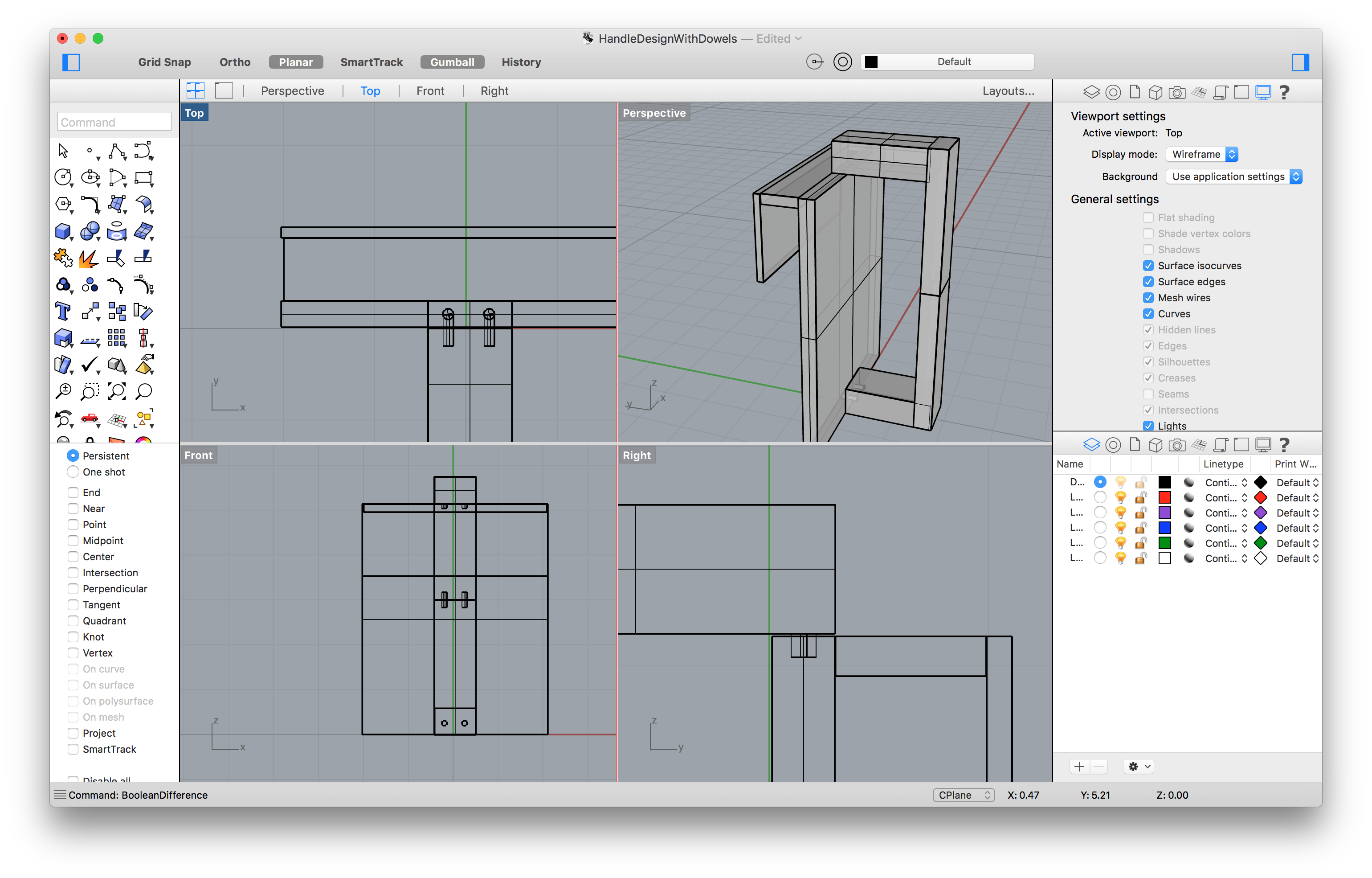

From here I started building a to-scale version, based on the drawer measurements I'd taken earlier. The first version used basic shapes to get the dimensions to be correct, and figure out the layout everything should have.

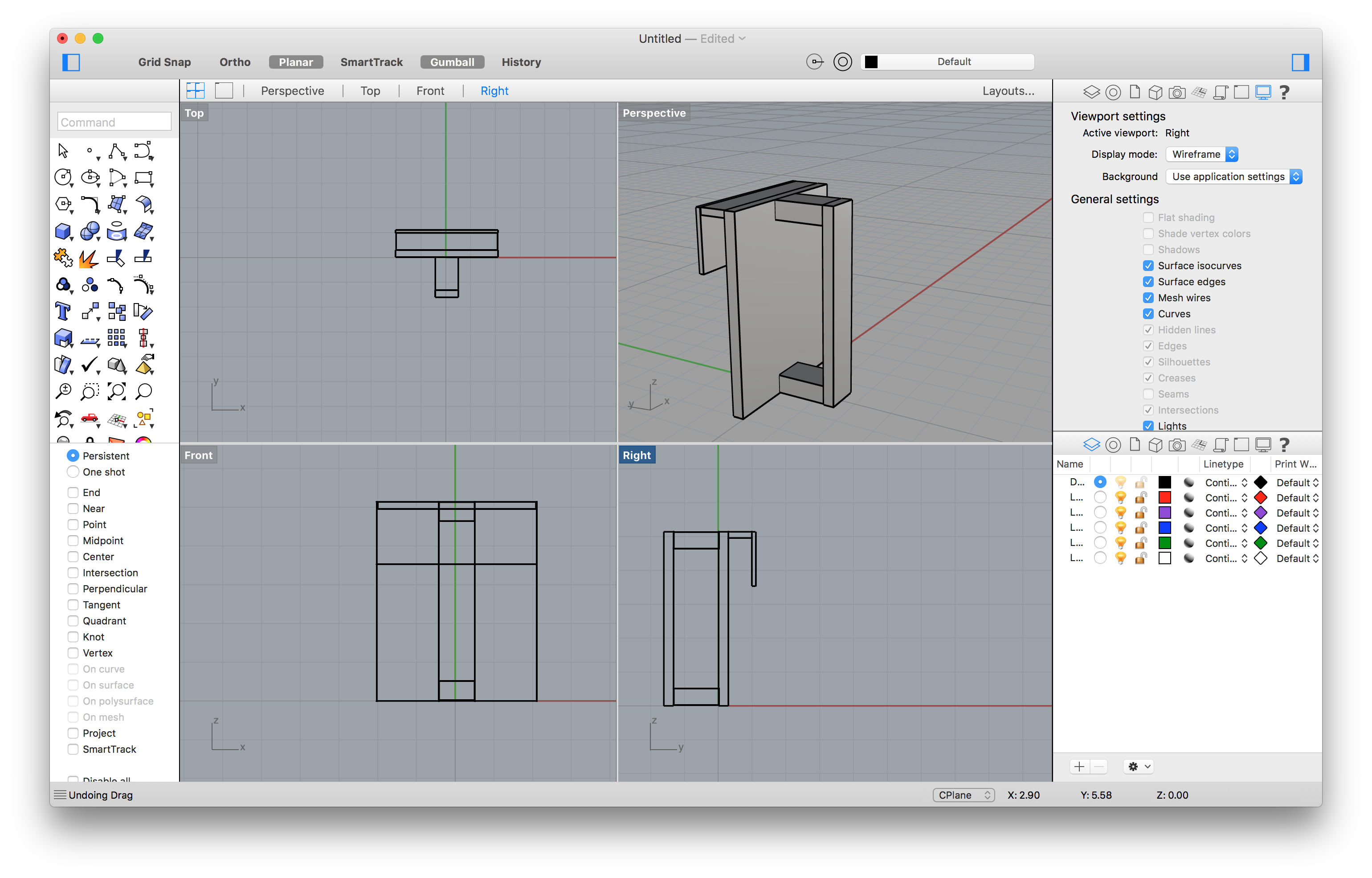

When I took a second look at this, I realized printing it all in one go might not be the ideal option (either if a piece breaks, and to ensure it would fit on a printing bed and use less support material).

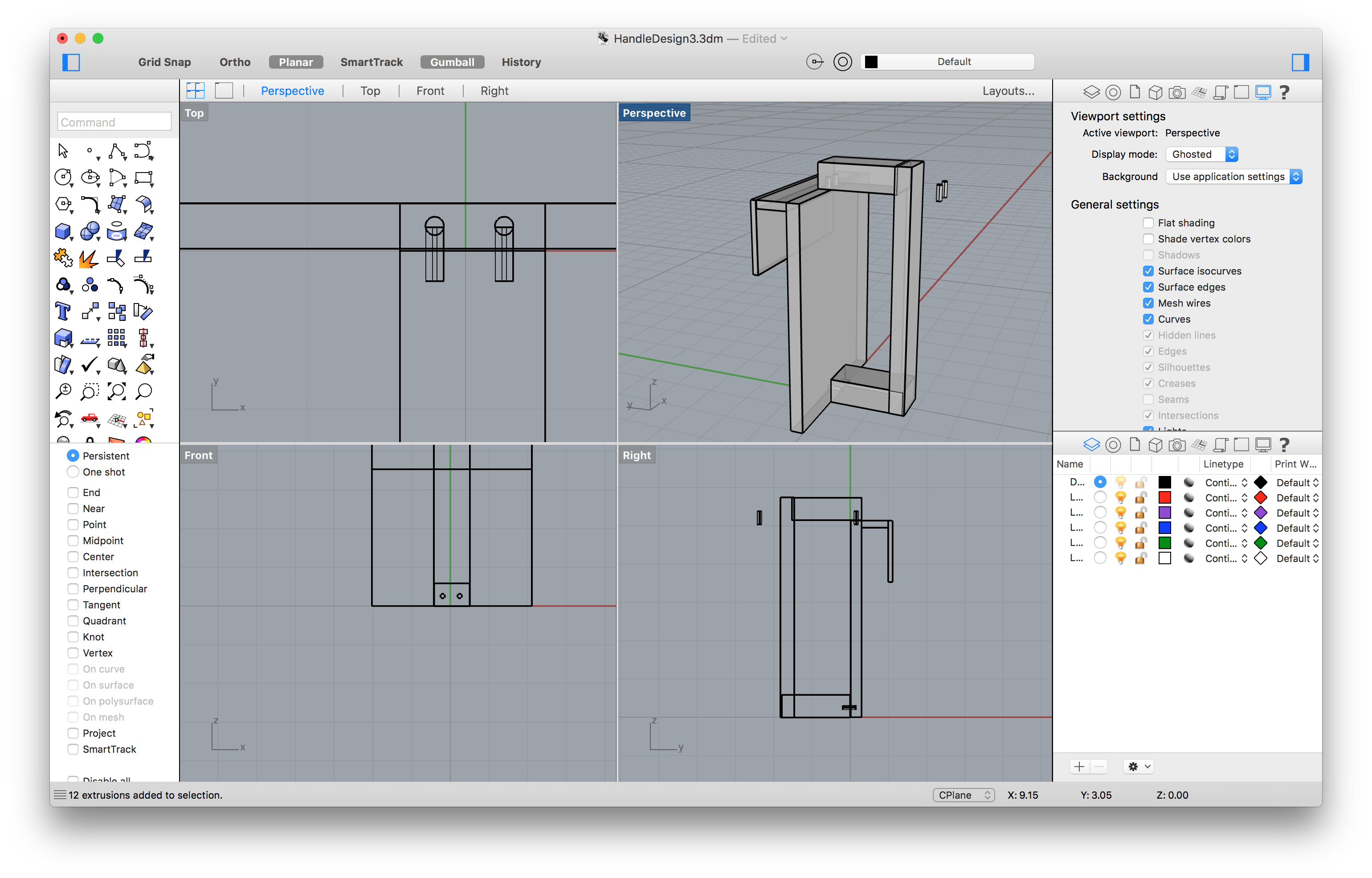

I adjusted the shape of the handle bit just enough to let it hang off the main frame. Then I could begin adding in dowels - the positioning of them came before I split the original objects, ensuring the would line up with one another.

I decided there would be one set of dowels anchoring it to the attachment frame on top, and then to also split the handle into two pieces so it would attached without needing to bend. The lower piece of the handle has two sets of dowels to hold it in place with the top piece of the handle, preventing the need for cutting and bending (though some adhesive would make the bond stronger it likely wouldn't be necessary.

Alessia Ianni-Palarchio

Alessia Ianni-Palarchio

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.