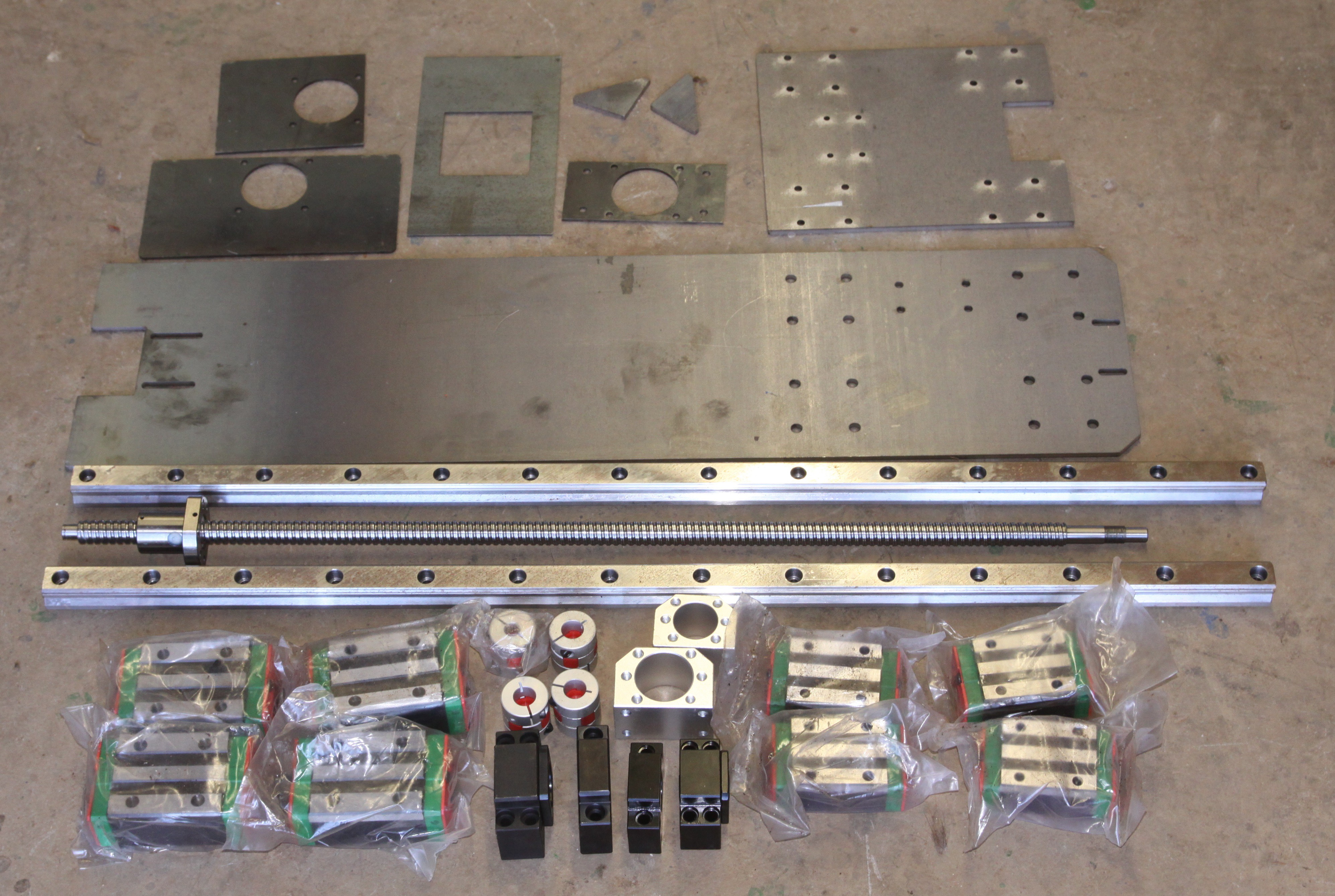

I had planned to build the CNC later on in 2018, but I just could not restrain myself! Previously, two saddles were installed on the 200 x 100 box section for the X axis. With some extra rails and ballscrew for the Y axis (Not shown) these are the components to finish the CNC build (Motors not shown).

Capt. Flatus O'Flaherty ☠

Capt. Flatus O'Flaherty ☠

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

@TegwynTwmffat☠ this approach seems like you will have to do lots of environmental protection of the linear motion system. Are you concerned about clogging or corrosion in use or do you think it will be more for prototyping, with less vulnerable materials in the longer term? I'm thinking eg v slot extrusion and delrin wheeled carriages.

Are you sure? yes | no

☠ Yes the soil could well cause problems. I was thinking of putting a shroud around the rotating claw to stop soil from getting sprayed everywhere. Have you got any links for v slot extrusion and delrin wheeled carriages?

Are you sure? yes | no

http://ooznest.co.uk/V-Slot

https://www.robocutters.co.uk/categories.asp?cat=25

I bought mine from robocutters. They were prepared to cut it exactly as I wanted when I emailed them. You could buy from China but I found it wasn't worth it by the time you pay for shipping, at least for the aluminium.

Would you be able to reveal some details about your plans for the end effector?

Are you sure? yes | no