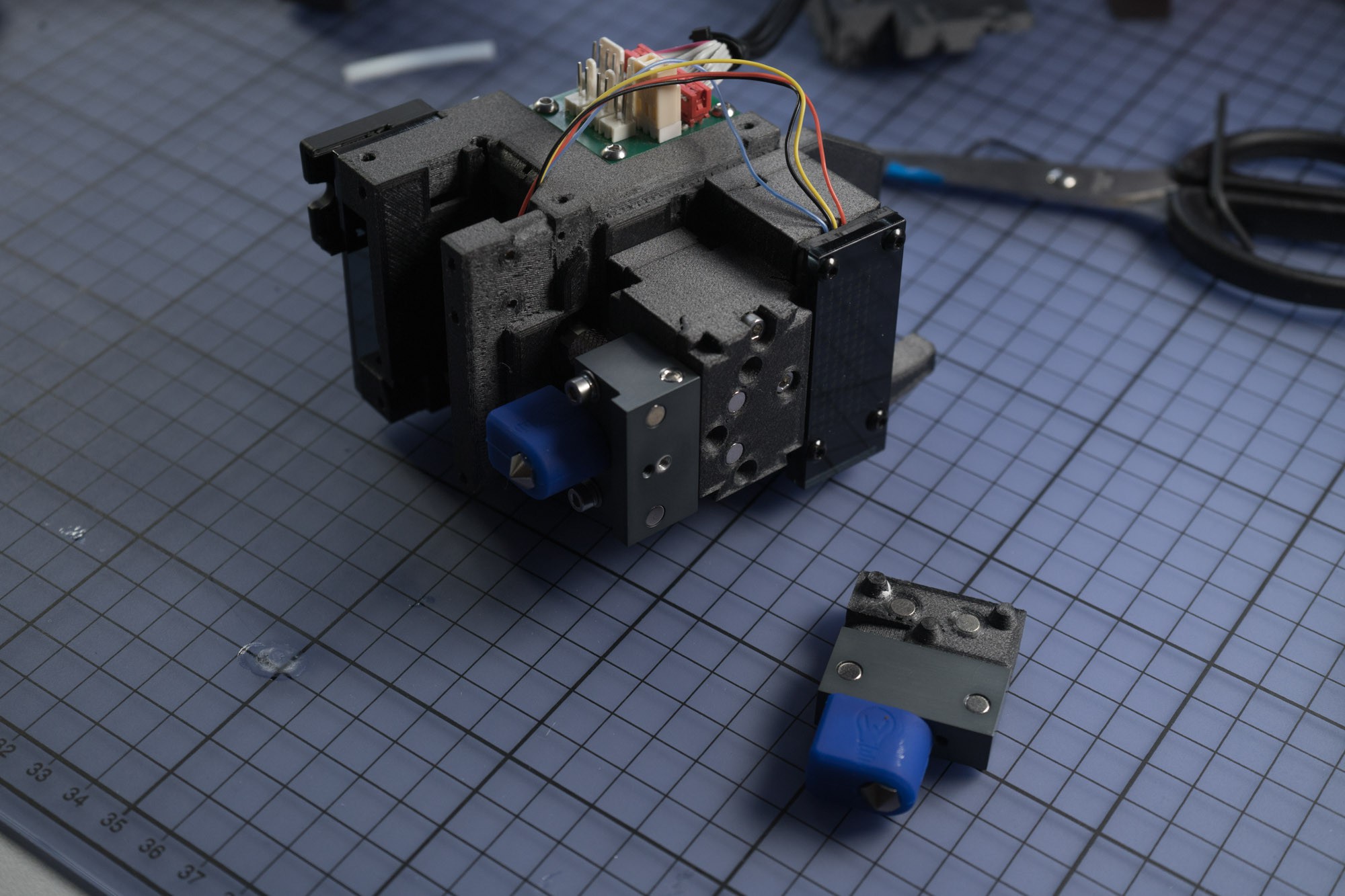

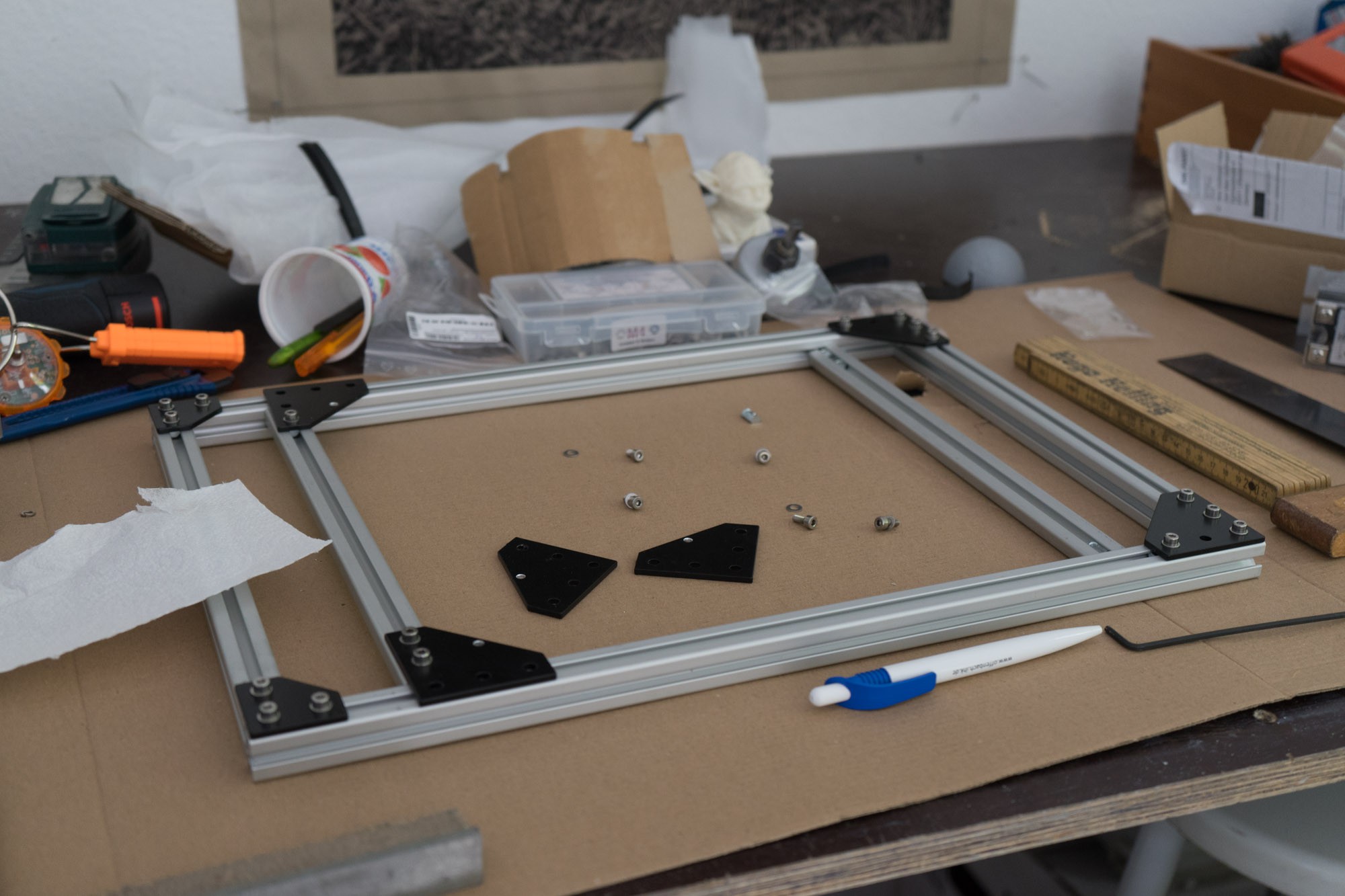

After several tolerance issues with my printer i was finally able to print the last iteration before the rebuild. The toolsystem looks good at first glance and i think i picked appropriate sized magnets. The new 8mm Z-Axis including heatbed is also ready for the big rebuild at the weekend. There is still an issue with the printed pulley, I still haven't managed to print a pulley that doesn't wobble.

Here is a small demo of the extruder toolchange mechanism

I used regular 2k epoxy glue for the Magnets. I had to buy way more magnets than necessary because they got big variance in tolerance.

X-Axis weight: ca. 400g

Tool weight: ca. 36g

Belt tensioner on the Z-Axis, hopefully strong enough to hold this massive aluminium bed.

Marc Schömann

Marc Schömann

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.