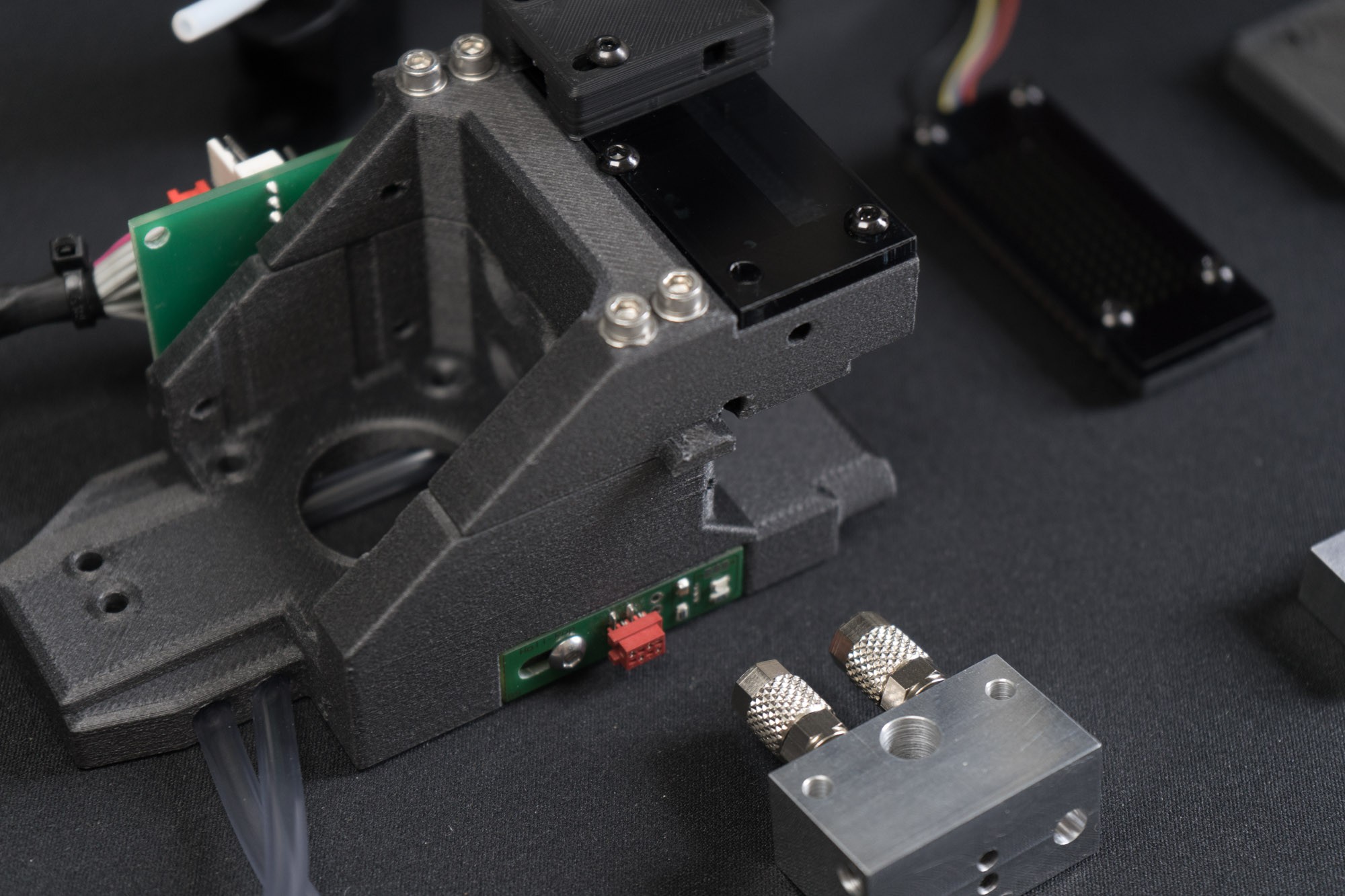

The CNC Parts are back from the shop, and they are awesome!

I had to wait two weeks for them, but it was worth it. Next step will be sanding and anodising the parts. I think this is necessary to prevent corrosion, but also to achieve a harder Surface for the tool changer.

X-Axis/Extruder and the mastercooler which will cool the direct drive extruder directly and the tools indirectly

i wanted to use compression fittings known from PC watercool systems. They turned out to be way too heavy so i swapped them with PE fittings used in the chemical industry.

While i waited for the tools to be machined i worked on how the hoses are guided along the energy chain.

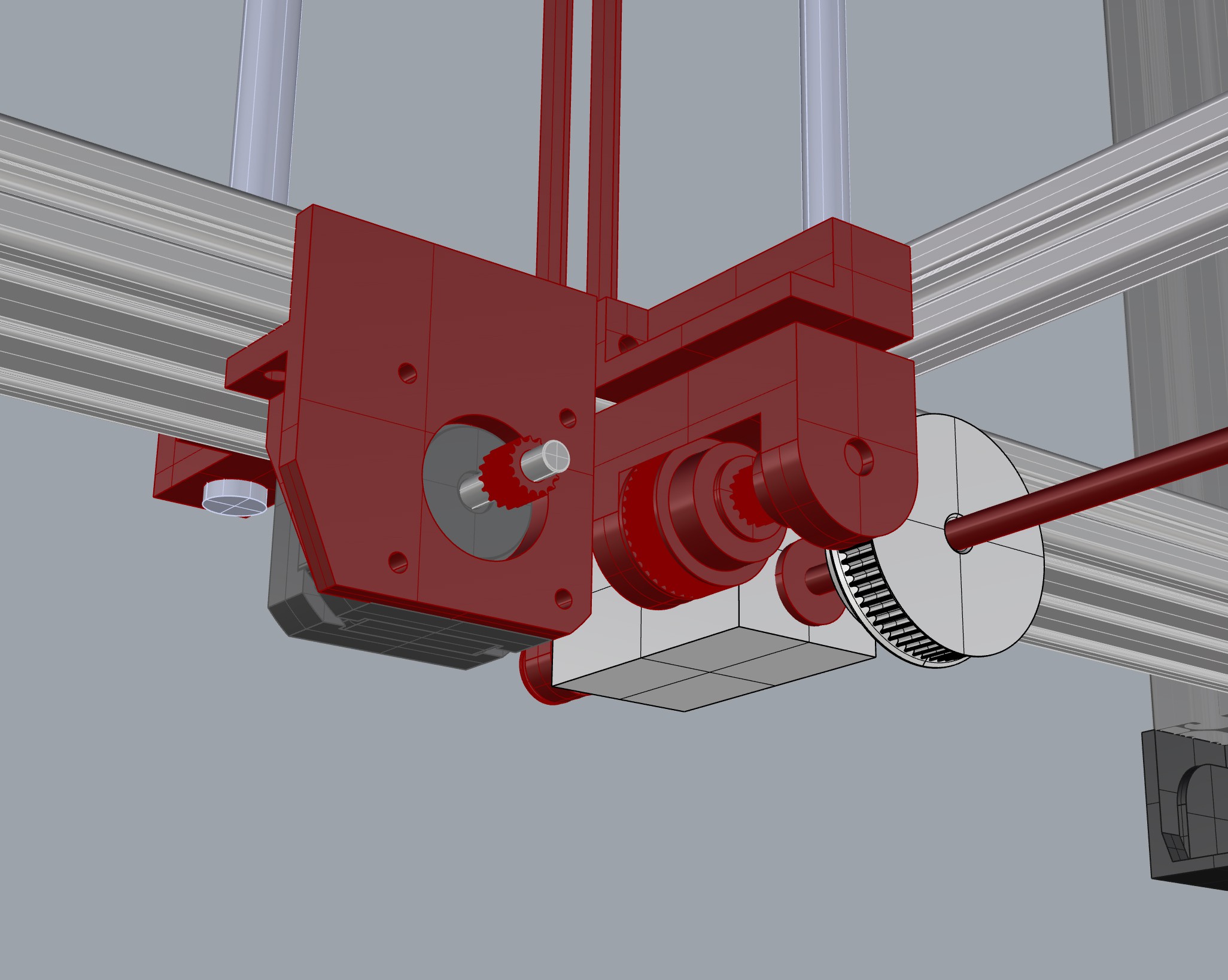

Z-Axis is also on a good way, the tension mechanism is ready, just a few brackets left to do.

Marc Schömann

Marc Schömann

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.