Date: 11/1/2017

That black goo you see above is what's left of the original bobbin winder mechanism inside our Brother sewing machine. Apparently, rather than using a gear or just any other mechanism that makes sense, they manufactured these sewing machines with some kind of black rubber that melts into a viscus goo when it is confronted with friction.

The kind of friction required to wind a bobbin. As in a bobbin winder that melts into goo whenever it is asked to perform the sole task for which it was created.

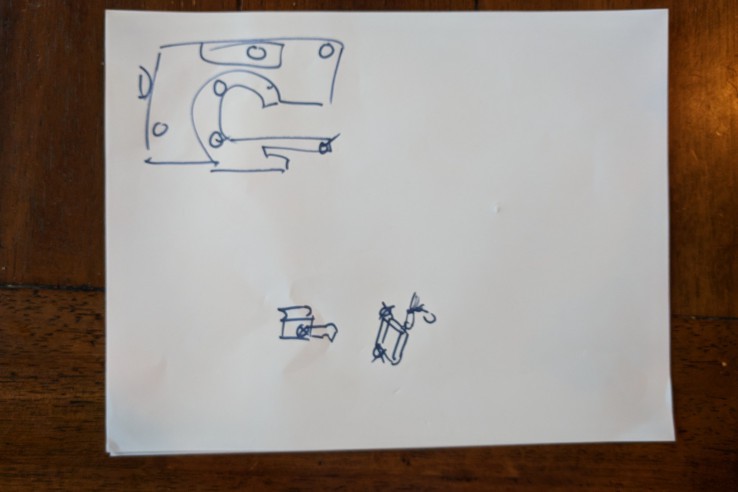

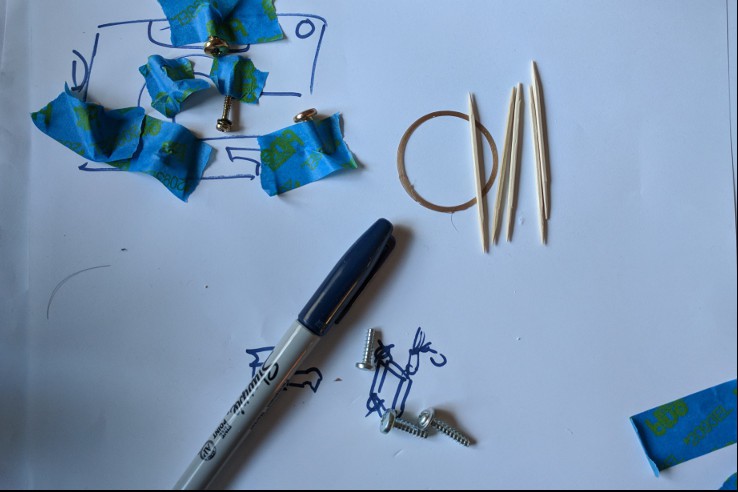

The next problem is that once it's been melted into go, there's no long a part to measure for fit. The fix involved using a combination of cotton swabs, toothpicks, and paper towels to clean the rubberized goo out of the machine, then measuring the pin the old bobbin winder tire must have once fit on. I made some educated guesses about how big the bobbin winder tire should be, whipped up a design in OpenSCAD, printed, and installed it.

Since this contest entry is really a collection of entries, I've uploaded the STL and OpenSCAD files to Thingiverse here.

MakerBlock

MakerBlock

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.