First frame again shows full pressurization, nice looking exhaust and geometry.

And here's another frame showing nozzle blow out.

This attempt was completed utilizing 3M fire caulking to try and block exhaust gases. It is obvious from this test that this method does not work.

Next to try after curing is a new method that includes PVC inner rings on both sides of the washer choke, large through wall shearing points, double couplers for convergent casting and high temperature paint. Hopefully this process will resolve the nozzle failures at the high exhaust speeds present in the H268 motor design.

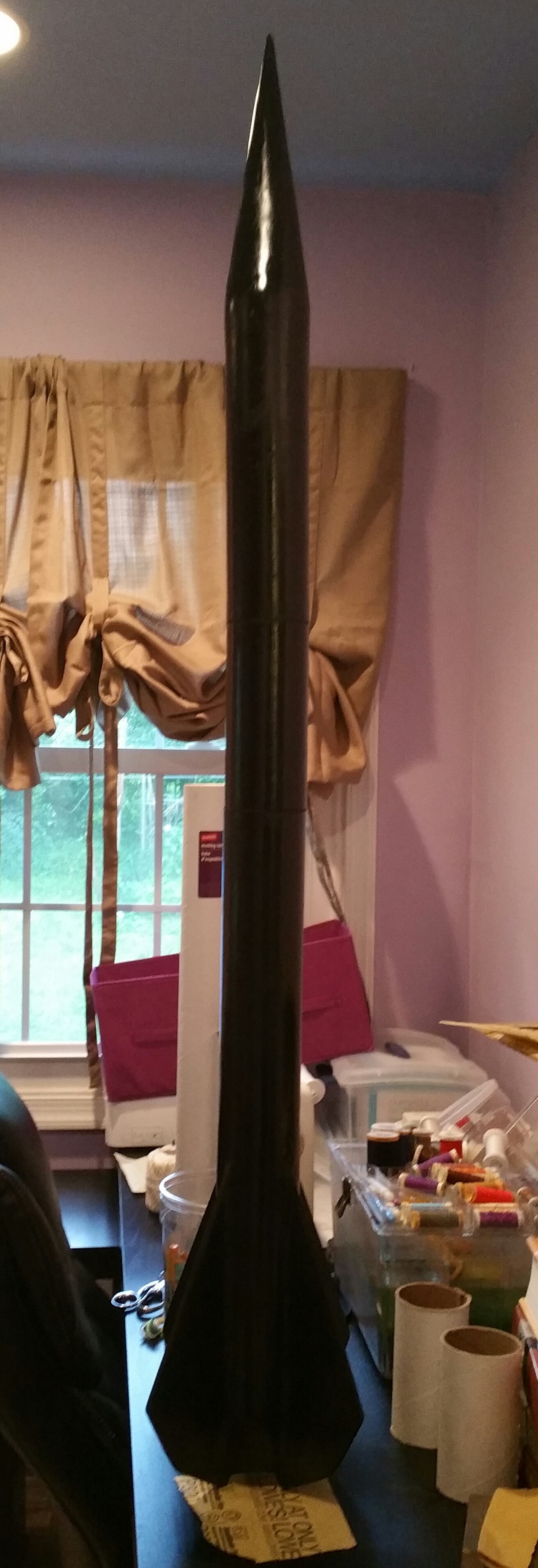

Construction of the rocket is progressing nicely though.

J. M. Hopkins

J. M. Hopkins

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.