In the attempts to alleviate the issues with traditional sucrose based grain brittleness I had switched over to a formulation that used corn-syrup as a humectant and secondary binder. This allowed for the grains to be malleable after casting without the brittleness that plagued early sucrose based propellants.

This post will explain the chemical and physical properties of my new propellant known as PNCP #6 (https://drive.google.com/open?id=1-6AqZODjtBV812eASCuXsPut8QYr2bl7j2L7OMh38Tc).

I will be utilizing a propellant analysis tool known as CHEM [3], which is itself similar to the program known as PEP which is the Propellant Evaluation Program (and its cousins PROPEP and GUIPEP). These programs are chemical equilibrium solvers, solving chemical equations using the “minimization of Gibbs free energy” [1]. Another similar program is the NASA Lewis chemical equilibrium program or CETPC [2].

The program allows you to enter different ingredients in percentages based on mass, and solves the chemical equations to tell you pertinent propellant information. The primary attributes that we are looking at are:

- Density, the weight in lb/in^3

- Temperature, combustion temperature is what helps us with materials engineering

- Gamma, our specific heat ratio, which is the heat capacity per unit of mass

- C-Star, or characteristic velocity, is a figure of thermo chemical merit

- Isp, Specific Impulse is the power of the fuel per unit of mass

The following table will compare :

- Traditional mixture (65% potassium nitrate/35% sucrose)

- Flexfuel mixture (65% potassium nitrate/18% corn syrup/17% sucrose)

- PNCP#6 mixture (65% potassium nitrate/18% corn syrup/8.5% sucrose/8.5% sorbitol) Full readout from CHEM here: https://docs.google.com/document/d/1OPSMKjqOTHAZuHPWtzrh5Q1walCyQBCP0ghi6VthN_8/pub

| 65/35 | 65/18/17 | 65/18/8.5/8.5 | |

| Density | 0.0682 lb/in^3 | .06679 | .06626 |

| Temperature | 2151 deg F | 2192 | 2131 |

| Gamma | 1.1451 | 1.145 | 1.1403 |

| C-Star | 2752.112 ft/sec | 2735.4 ft/sec | 2736.38 ft/sec |

| Isp | 138.8 | 139.1 | 138.3 |

At this time I cannot simulate the addition of potassium bitartrate or carboxymethyl-cellolose gum into CHEM (it only has a particular subset of chemicals in its database), but these chemicals reduce performance slightly (particularly at the lower levels used), so if we use these design characteristics, we will be simply making a higher safety margin.

We can input these characteristics into BurnSim [4] to model our motors. The only thing we need extra is burn rate information, which experimentally we are using burn rate coefficient of a=.035 and burn rate exponent of n=.35 which has experimentally aligned very well to our composition.

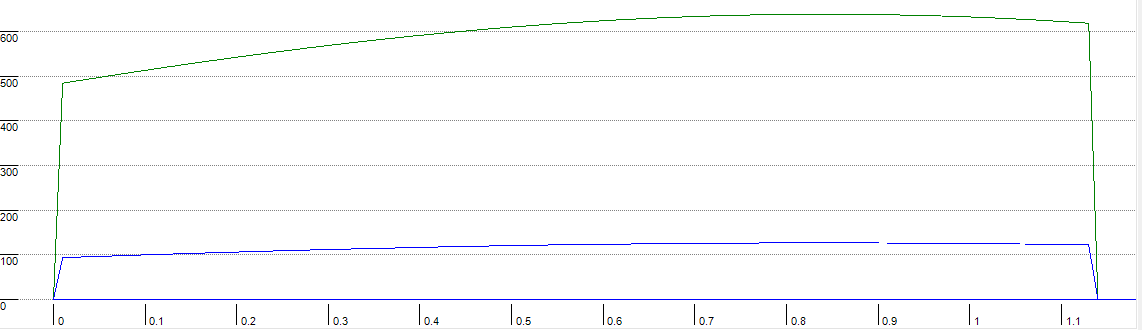

If we use the following grain information: 5 x (1.3”OD, 2.5”L, 0.5625”ID), 1 x (1.3”OD, 4”L, 0.5625”) with a nozzle of .4375” with 5X expansion, we get the following motor:

- Initial Kn: 280

- Max Kn: 335

- Max Pc: 639PSI

- Volume Loading: 81.3%

- Burn Time: 1.13 sec

- Propellant Length: 16.5”

- Propellant Mass: 1.189lb

- Total Impulse: 592NS

- Motor Class: 85% I-524

- Delivered ISP: 112 sec

And this is the thrust curve graph:

Overall this is a very nice, strong, slightly progressive motor capable of lofting a 5 lb rocket up to a mile or so. Not so shabby for sugar fuel!

[1] http://www.nakka-rocketry.net/th_prope.html

[2] http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19940028442.pdf

J. M. Hopkins

J. M. Hopkins

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.