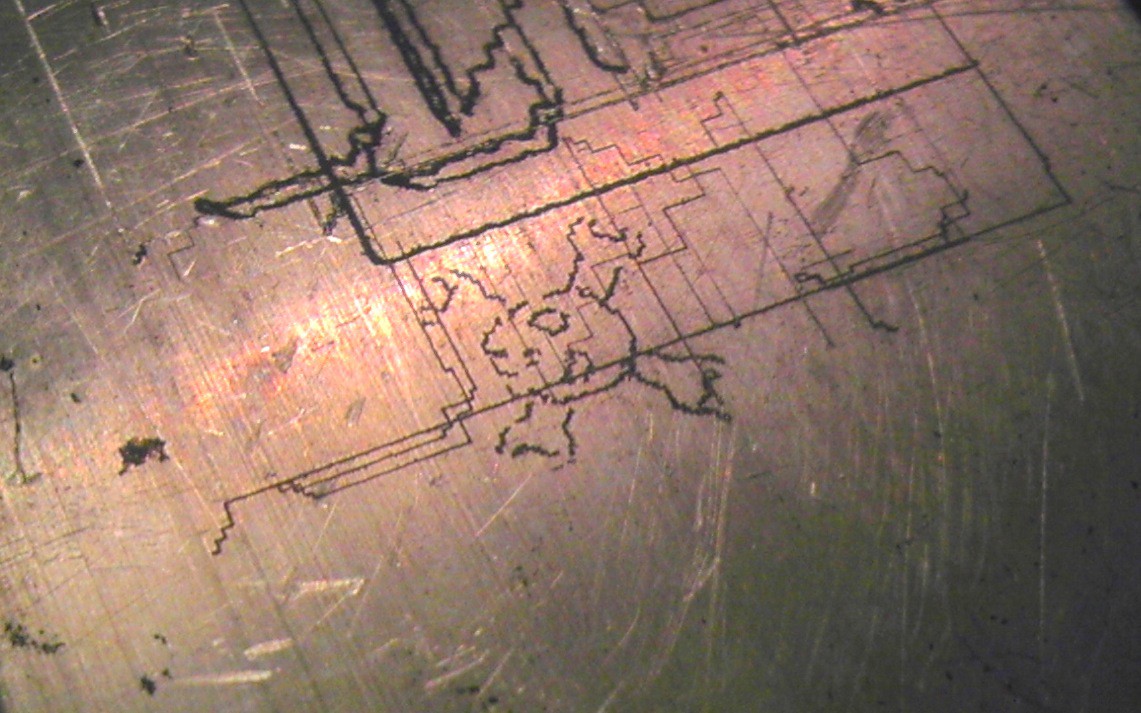

The end goal of this CNC was to be able to mill PCB, make stencils and any other tedious tasks of fine cutting. So adding a V mill bit is getting the machine one step closer. The software has just been moved to a g-code input as oppose to a image input.

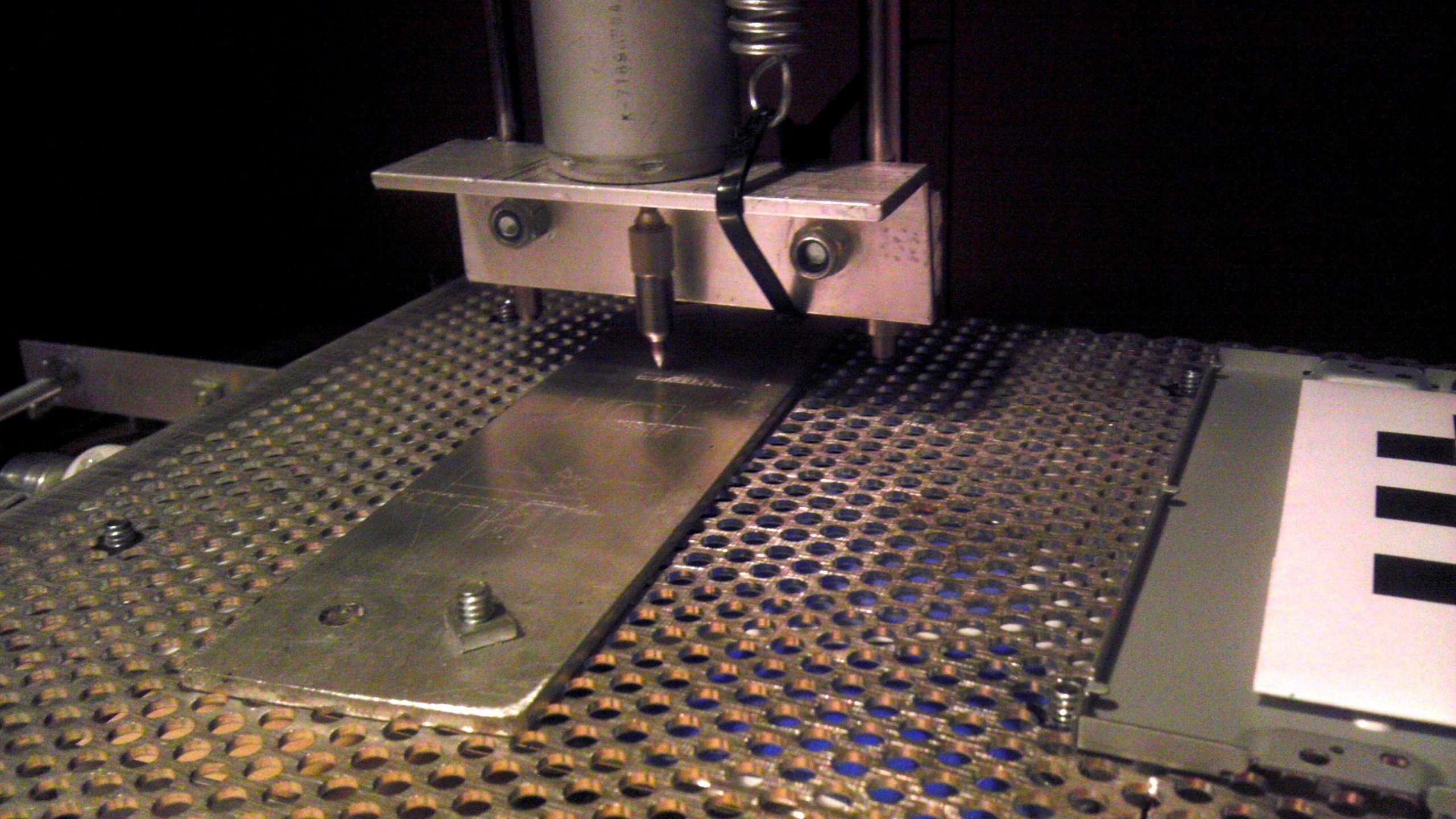

The bit is mounted in a head cut off from mini hand-drill, which has been soldered to the motor. The bit itself was a bit of rod with the tip ground to a V. There is very little lateral movement and can put a good scratch on a piece of aluminum.

The new software has issues with commanding the CNC. There are overshoots and Z-axis issues. New controls for cutting diagonal lines should also be considered. The current lines are in little steps.

JLAM

JLAM

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.