Basic plans and a starting point

I started off the project with a basic plan of dimensions for the shelf. The place that I chose to hang the shelf had some heating plumbing so I had to include that to the outer dimensions. I thought that I would need a strong material which was flat as possbile so I used an oak sheet which I used to have as a desk. I designed the project with a woodcarving software. For the logo i used the vector format of the hackaday-logo.

Woodcarving

The CNC router in the hacklab is a Kingcut W 1525. I had no previous experience of CNC-machines, but with trial and error i got the job done. I used a 30 mm end mill to flatten out the surface, a 6mm ball nose for the logo and a 6mm end mill for the rest.

|  |

For the bottom shelf I used the same dimensions as for the top one but i added recess for the nuts.

|  |

Putting pieces together

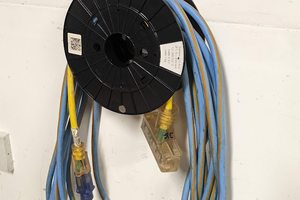

The 4mm clear acrylic sheet on top of the logo was cut using the hacklabs laser cutter. 6mm threaded rod was used to stack the shelves.

|  |

Timo Hyvönen

Timo Hyvönen

83000

83000

jeremy.geppert

jeremy.geppert