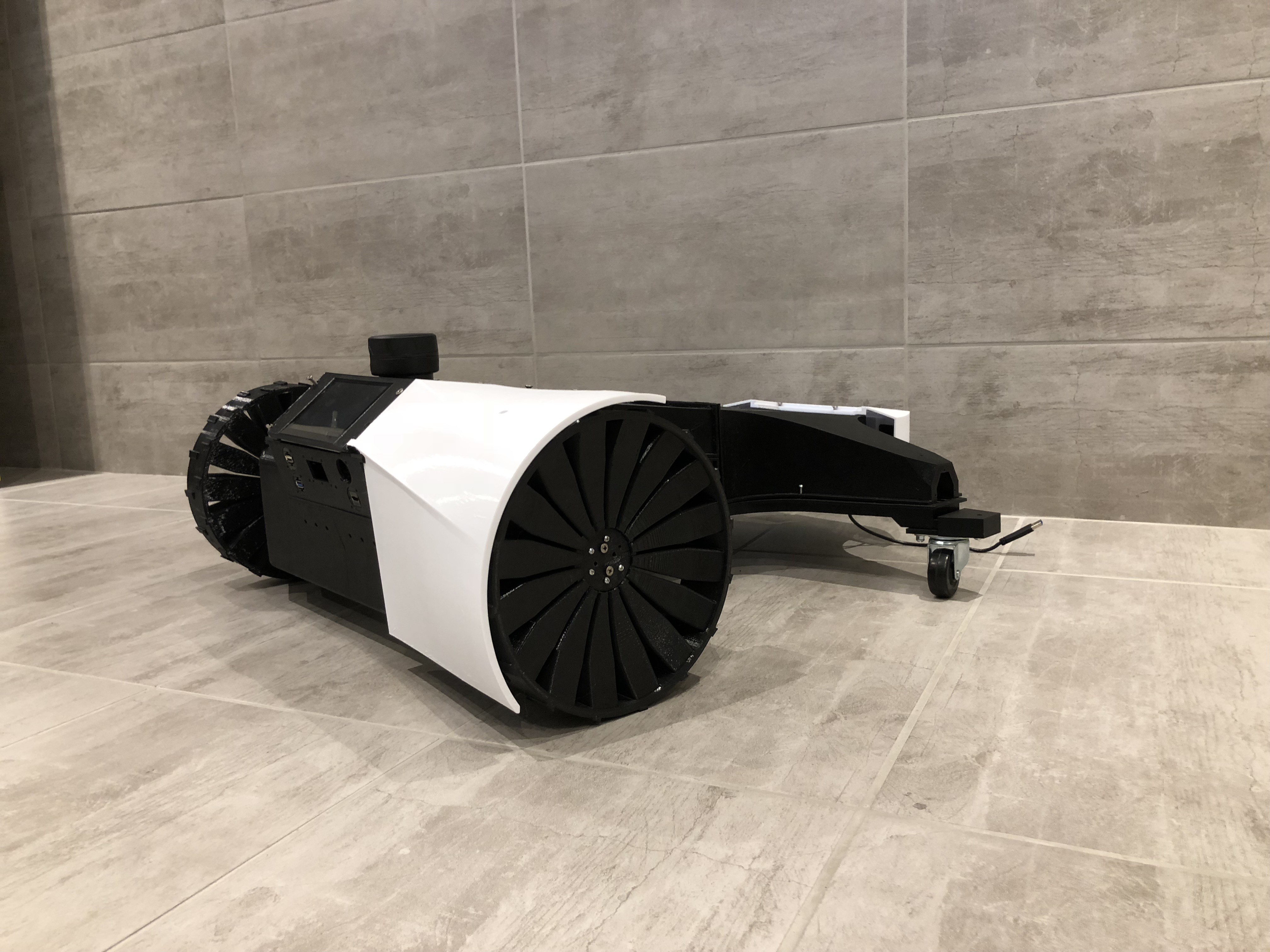

First big body cover printed. The part came out great. Running PrimaSelect PETG Solidwhite at 240C. This print was printed with 0.6mm nozzle instead of the original 0.4mm. layers looks nice and even! This part was printed at 2 shells at 10% infill and print time landed on around 15h.

The motor brackets are ready and just some minor things left to be CNC milled. Then finally I can assemble the drive system

Robin Fröjd

Robin Fröjd

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.