This log will include a few tips on 3D printing FEDs. Please feel free to add your own tips in the comments!

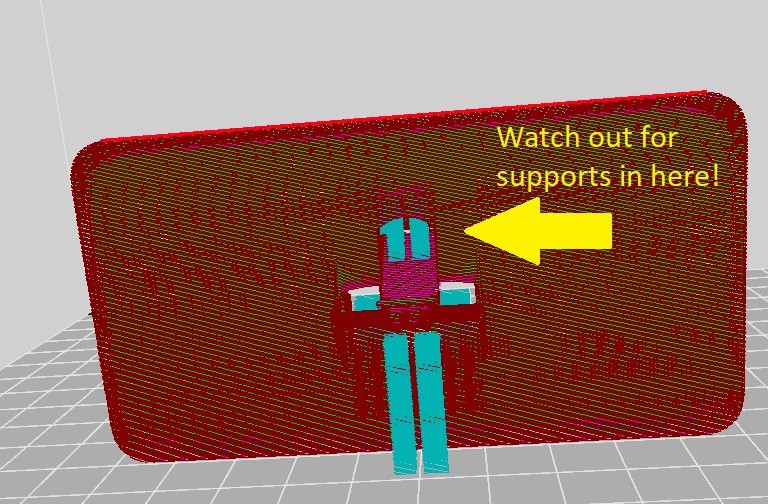

1. A note on suppports: The printer we use is cheap and does the job, the Sindoh 3DWox (This is not an endorsement of this printer over other printers BTW, just stating what we use). Because our printer doesn't print "support material", we have designed all of the parts to be printed with as few supports as possible. When you slice your models to print, it is possible that your software will want to add support. This may be OK for some parts, but you should remove any supports from inside the pellet "funnel". Stray plastic in here can cause pellet jams.

2. Inspect the pellet path for plastic strands. While it doesn't matter if they are on the housing, the FED is a mechanical device and imperfections in the pellet dispensing area or the pellet funnel can cause jams. Take care to look this over and make sure there aren't any stray pieces of plastic. For instance, in yellow I've circled a little piece that can interfere with the movement of the pellet disc in this print:

3. Different printers can produce parts with different tolerances and slightly different sizes. In particular, this can be a problem with tight-fitting parts, such as the sliding back door to FED. If your parts don't slide together nicely you may need to tweak the design a bit to get it dialed in for your printer. STL files are available in the files area.

Lex Kravitz

Lex Kravitz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.