I wanted the oven to be/do/have:

- small

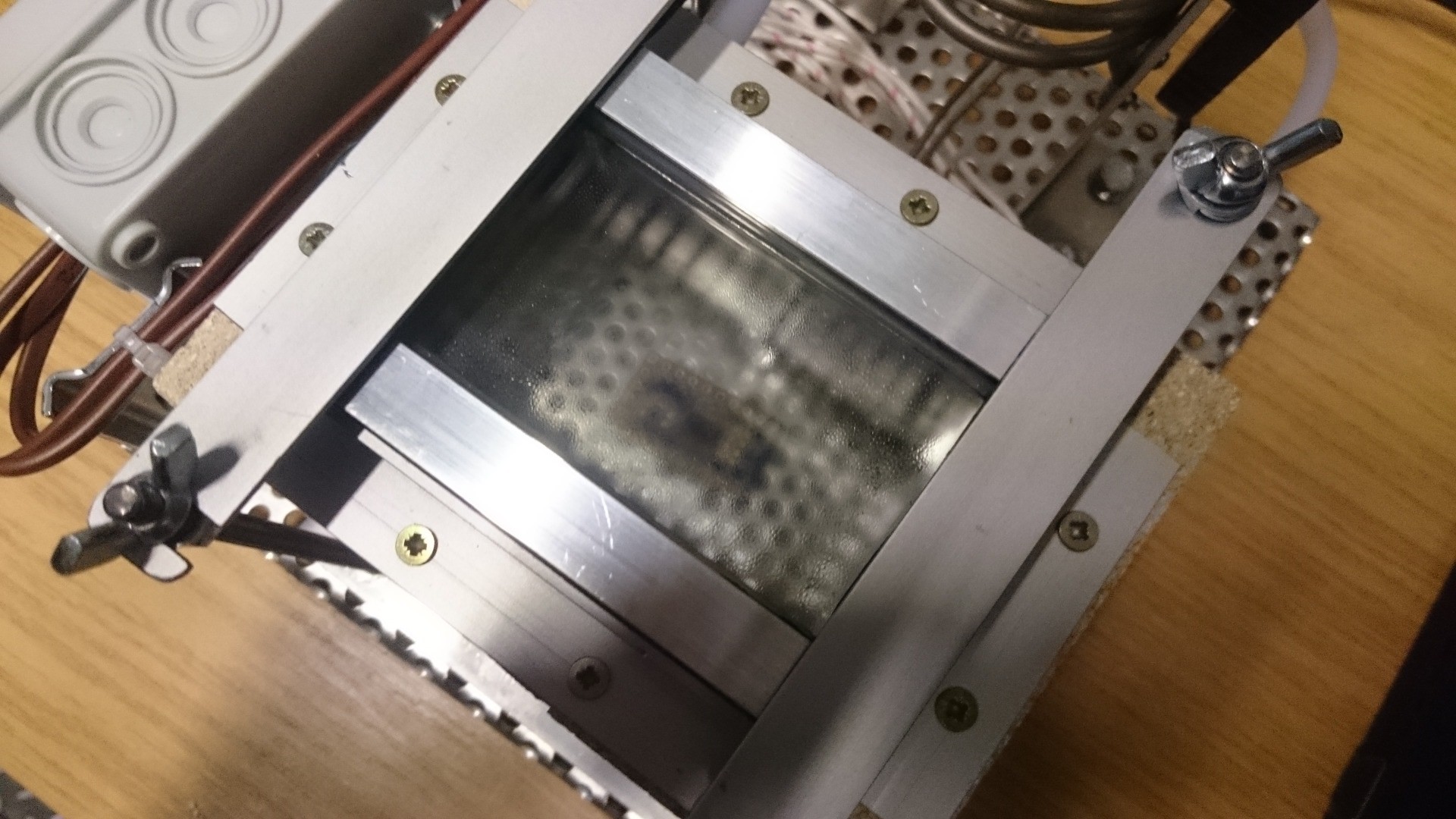

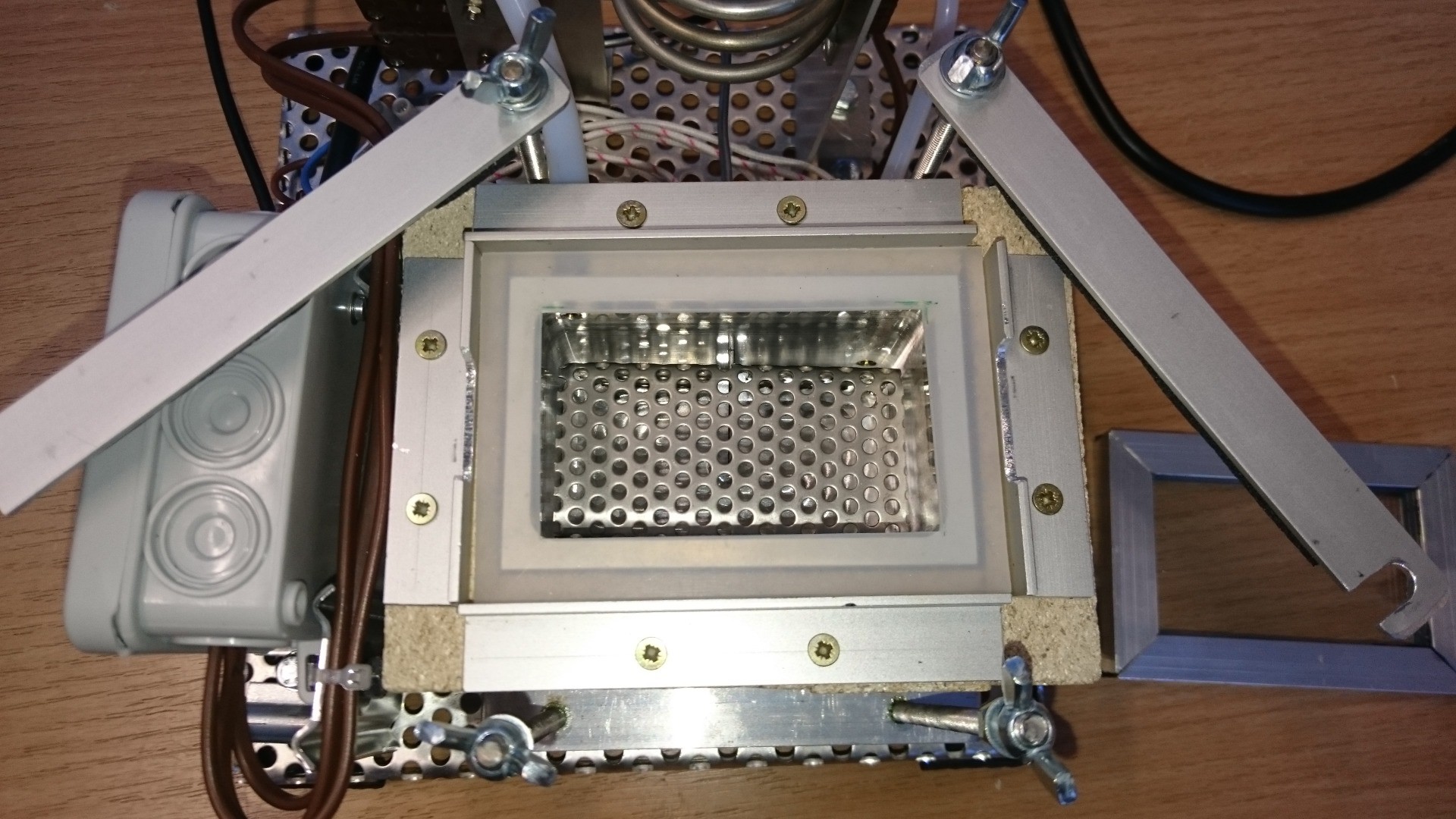

- transparent lid. I like to see what's going on in there

- keep the amount of escaping galden as low as reasonably possible

- galden that escapes the chamber should be trapped in such a way that it flows back to the heater

- shouldn't look like a frankenoven

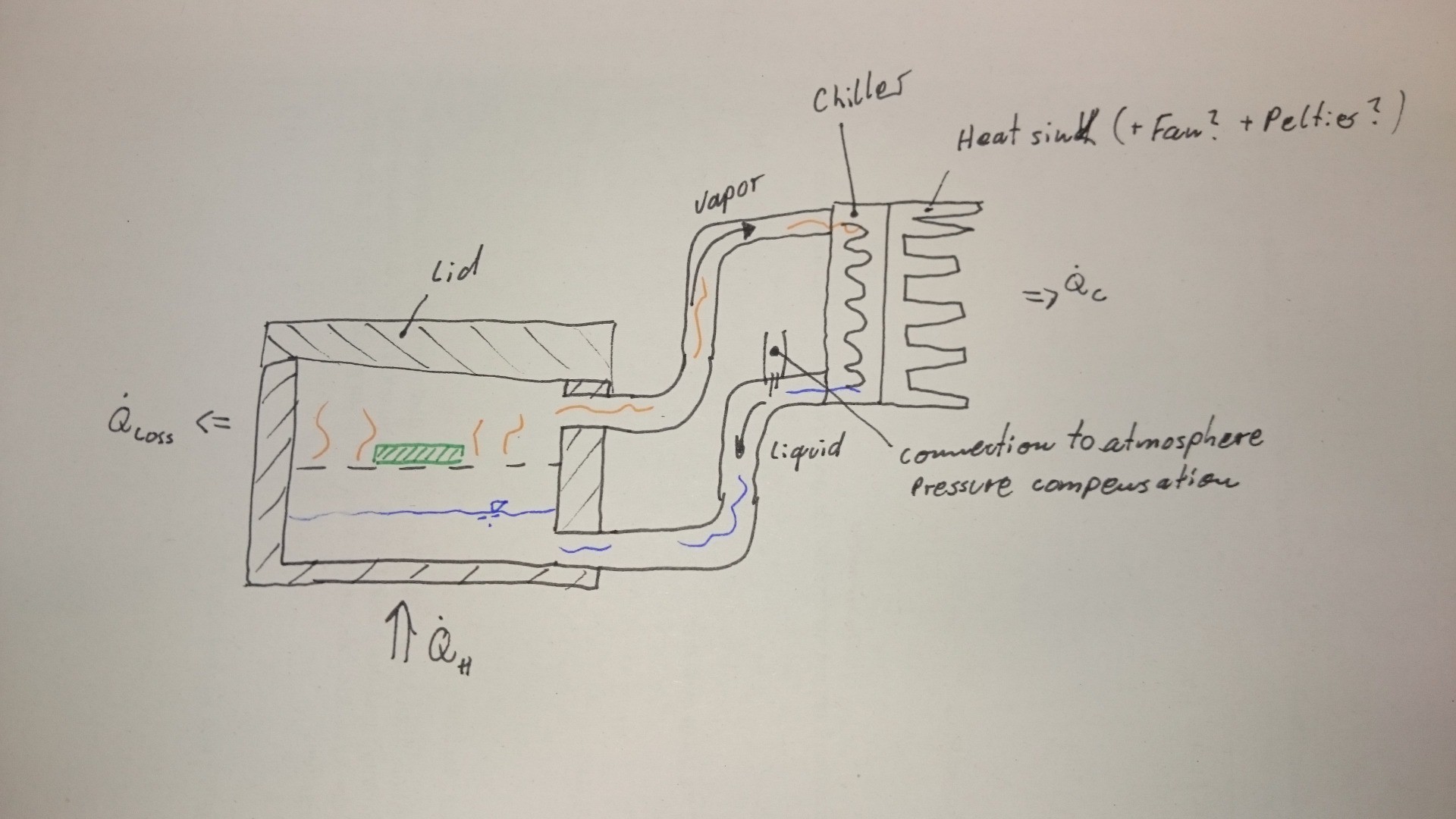

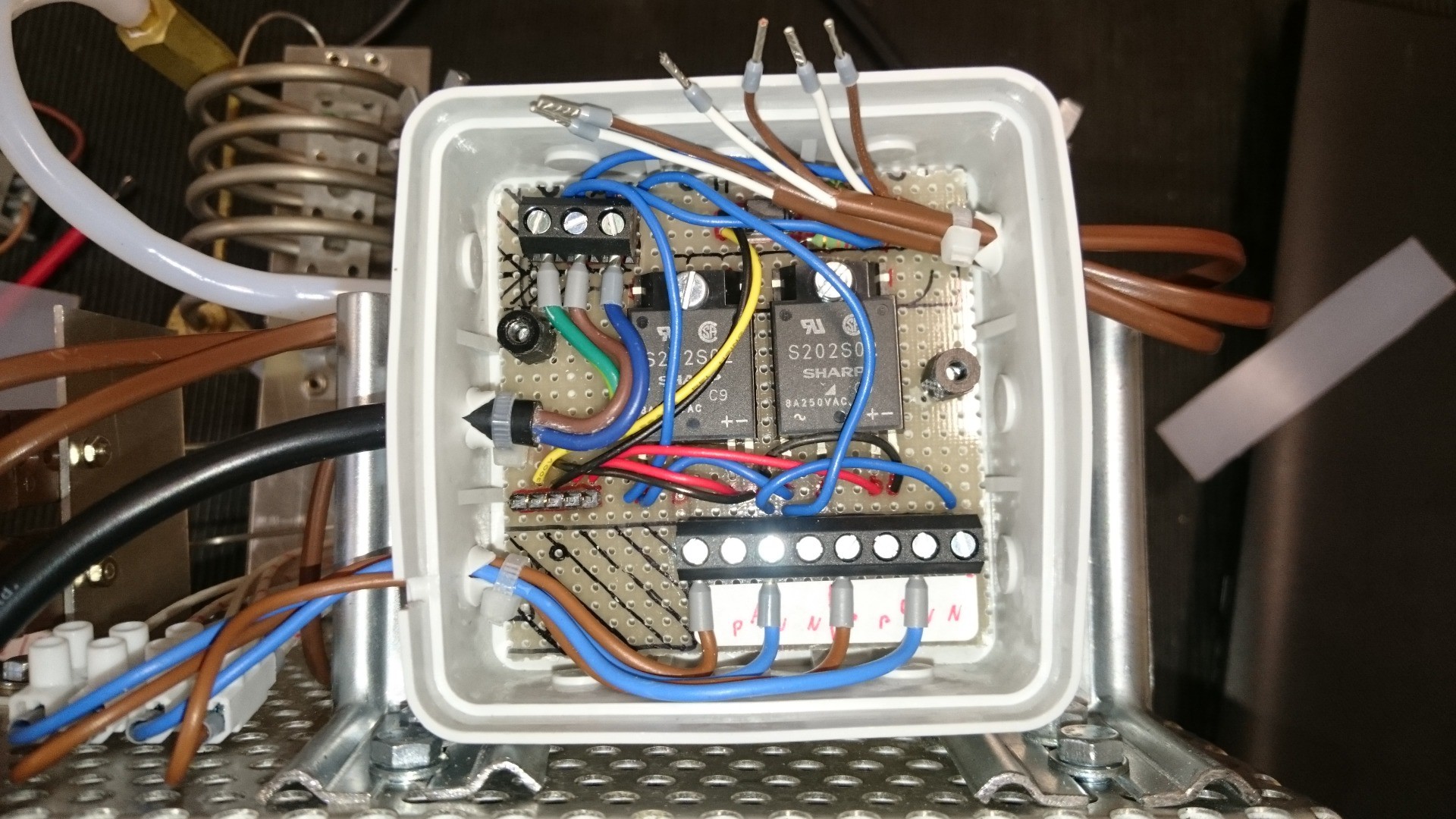

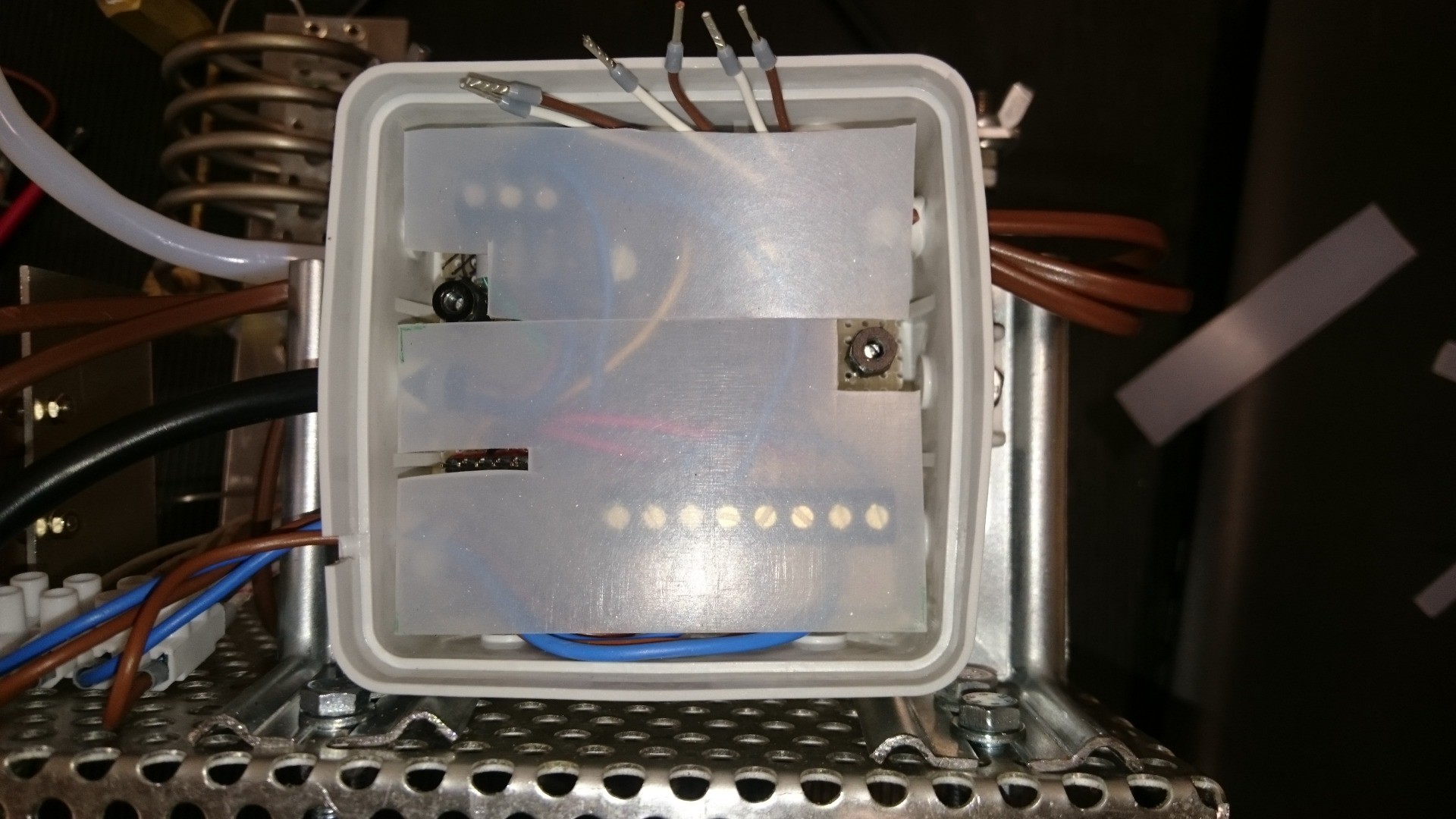

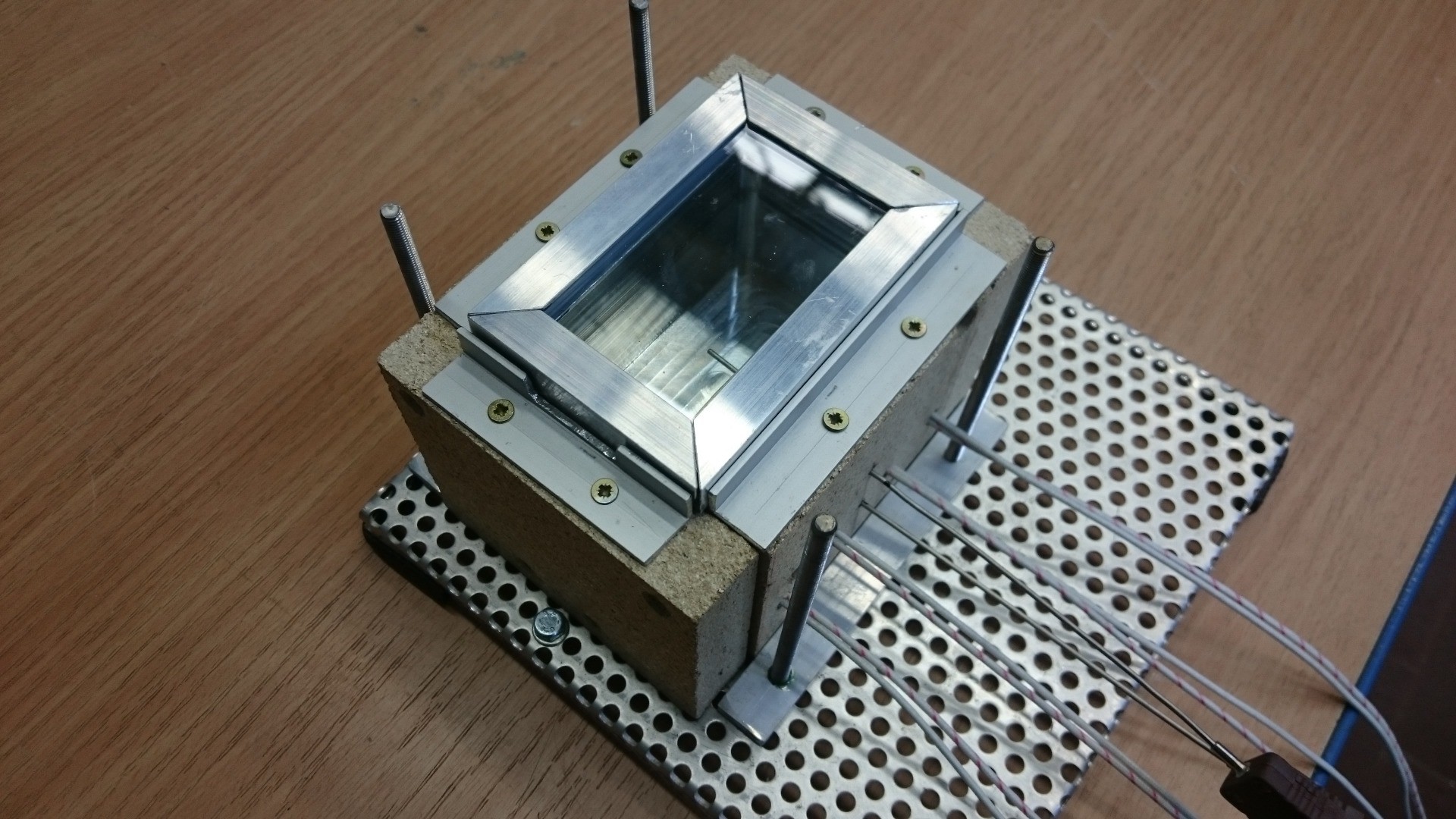

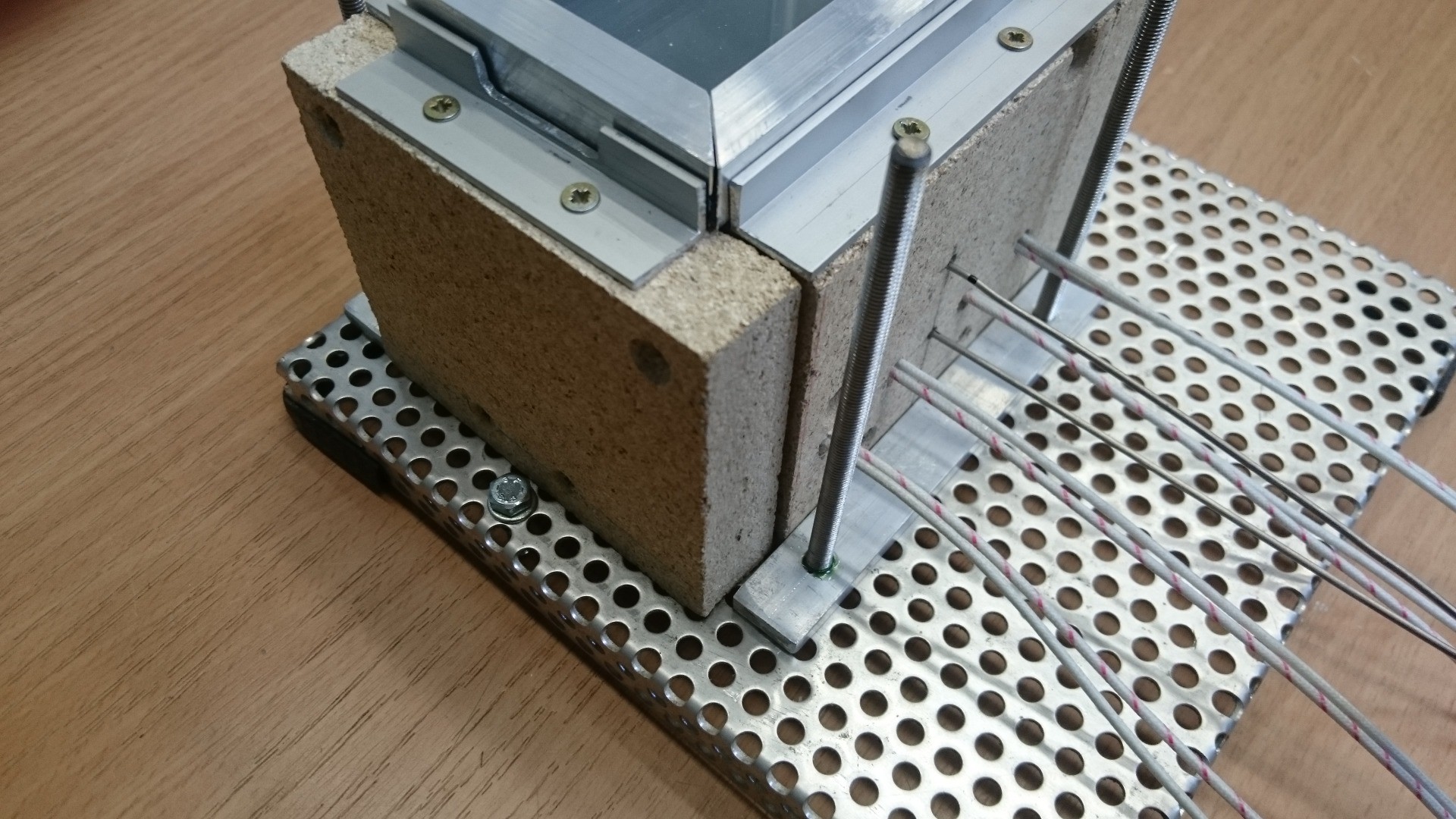

The implemented design resembles the idea outlined in this diagram:

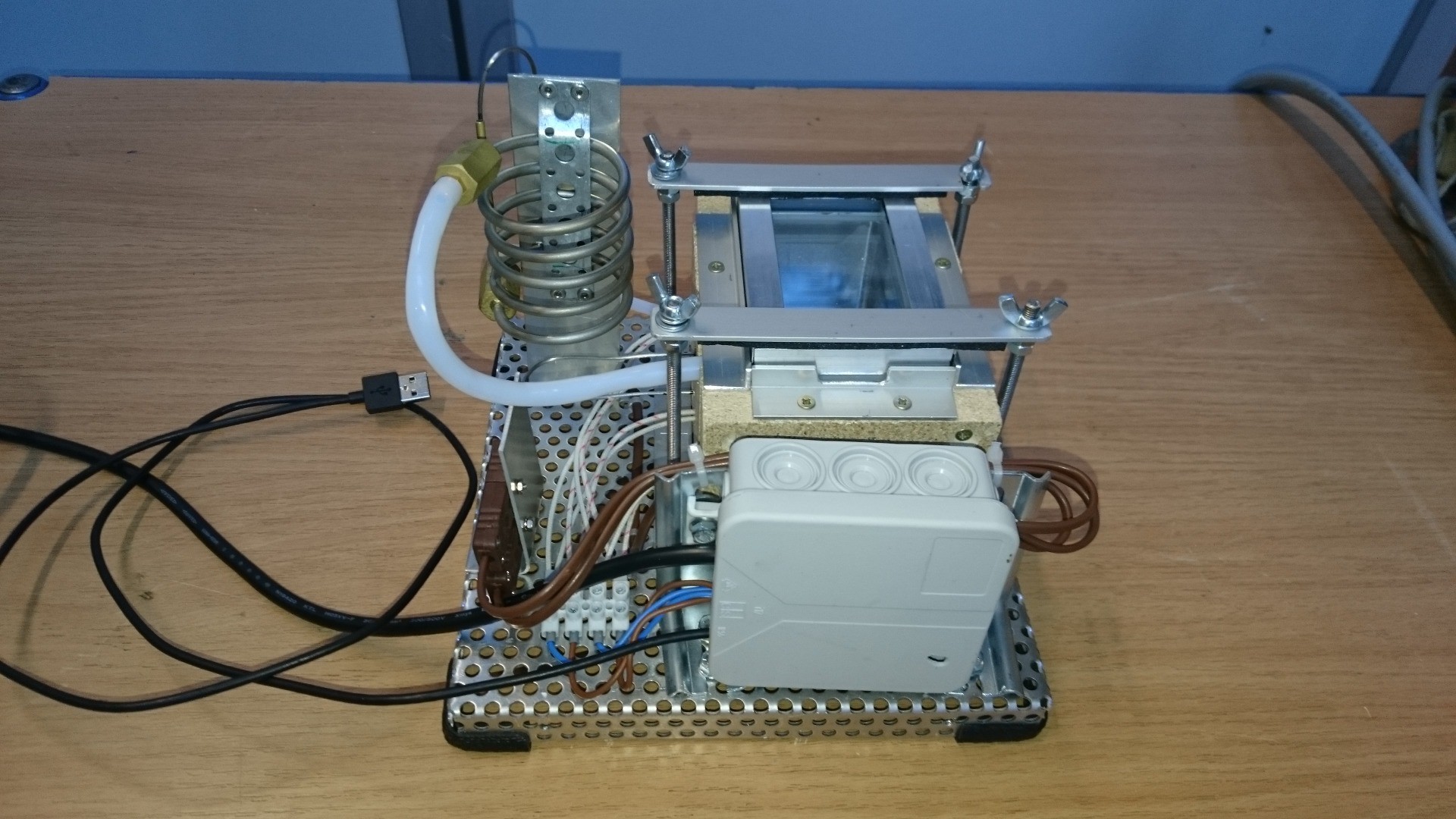

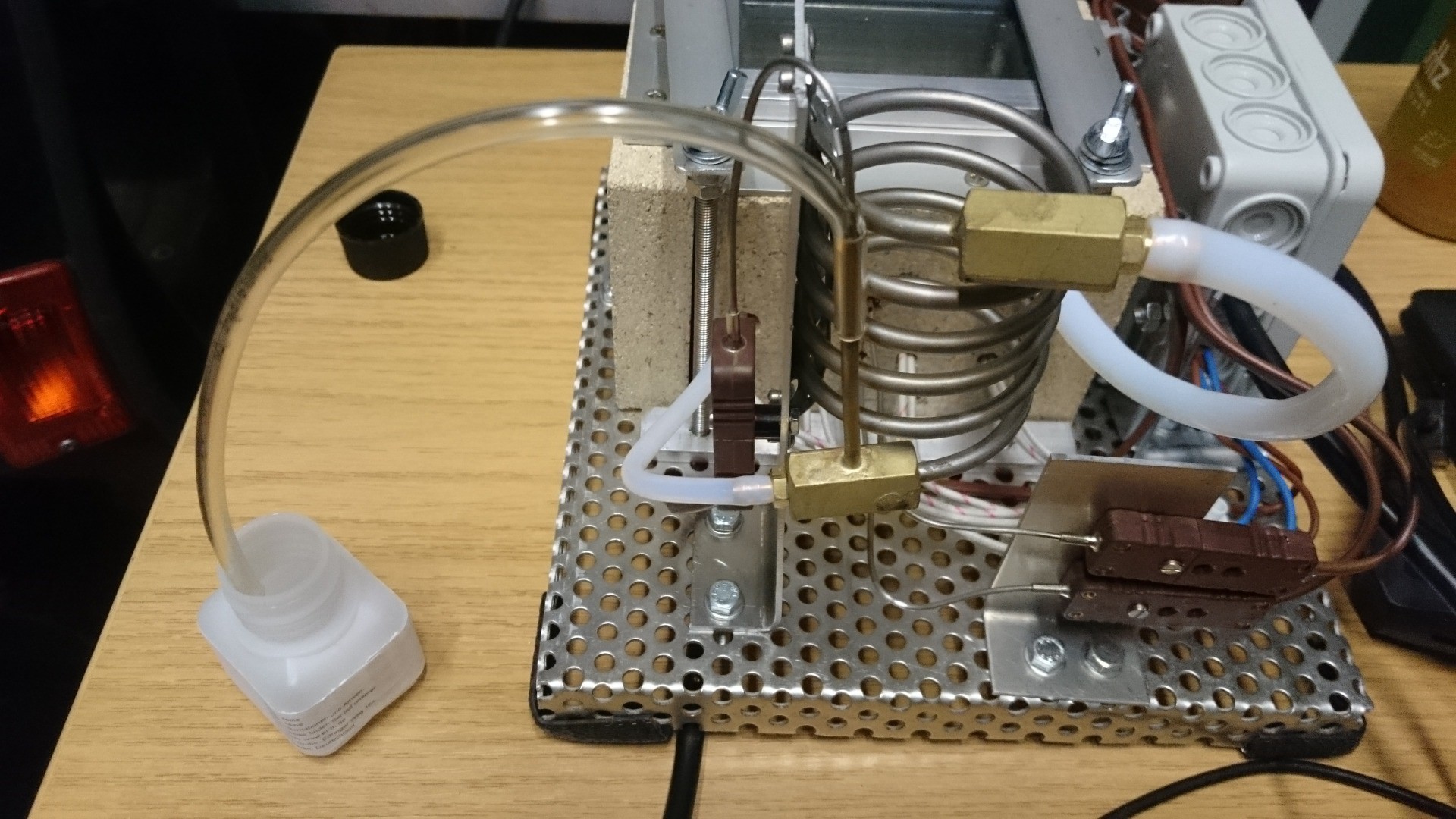

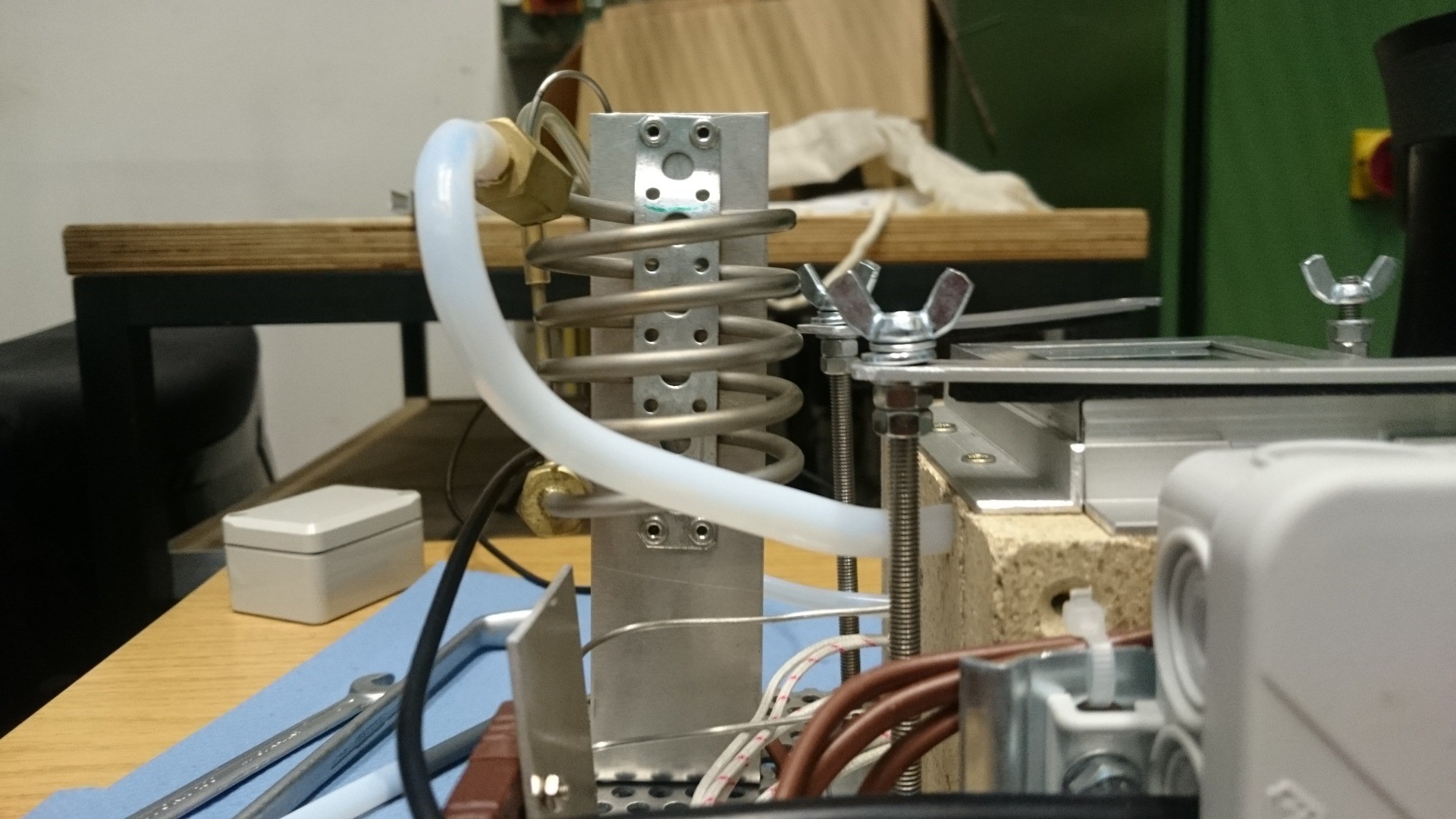

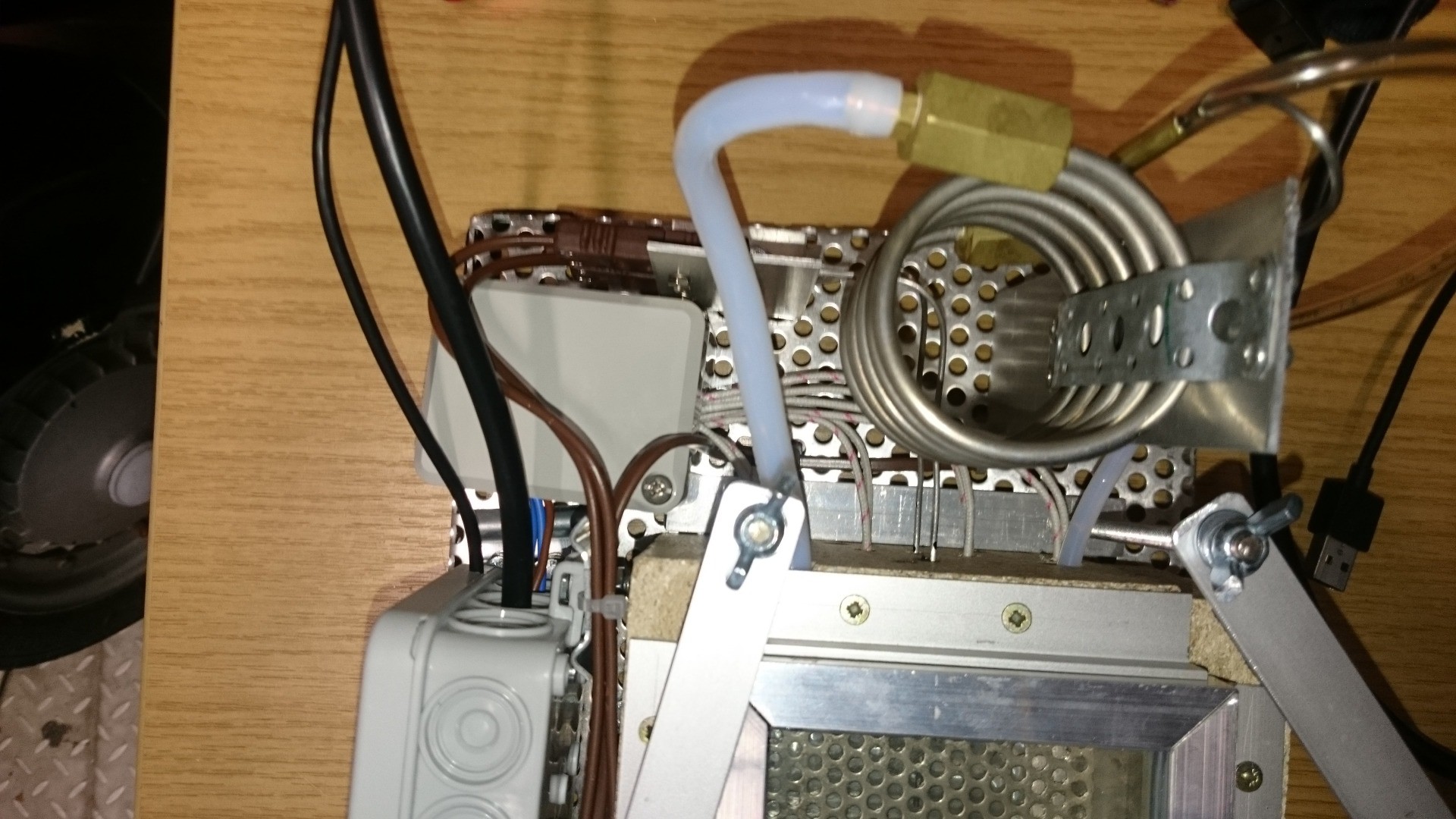

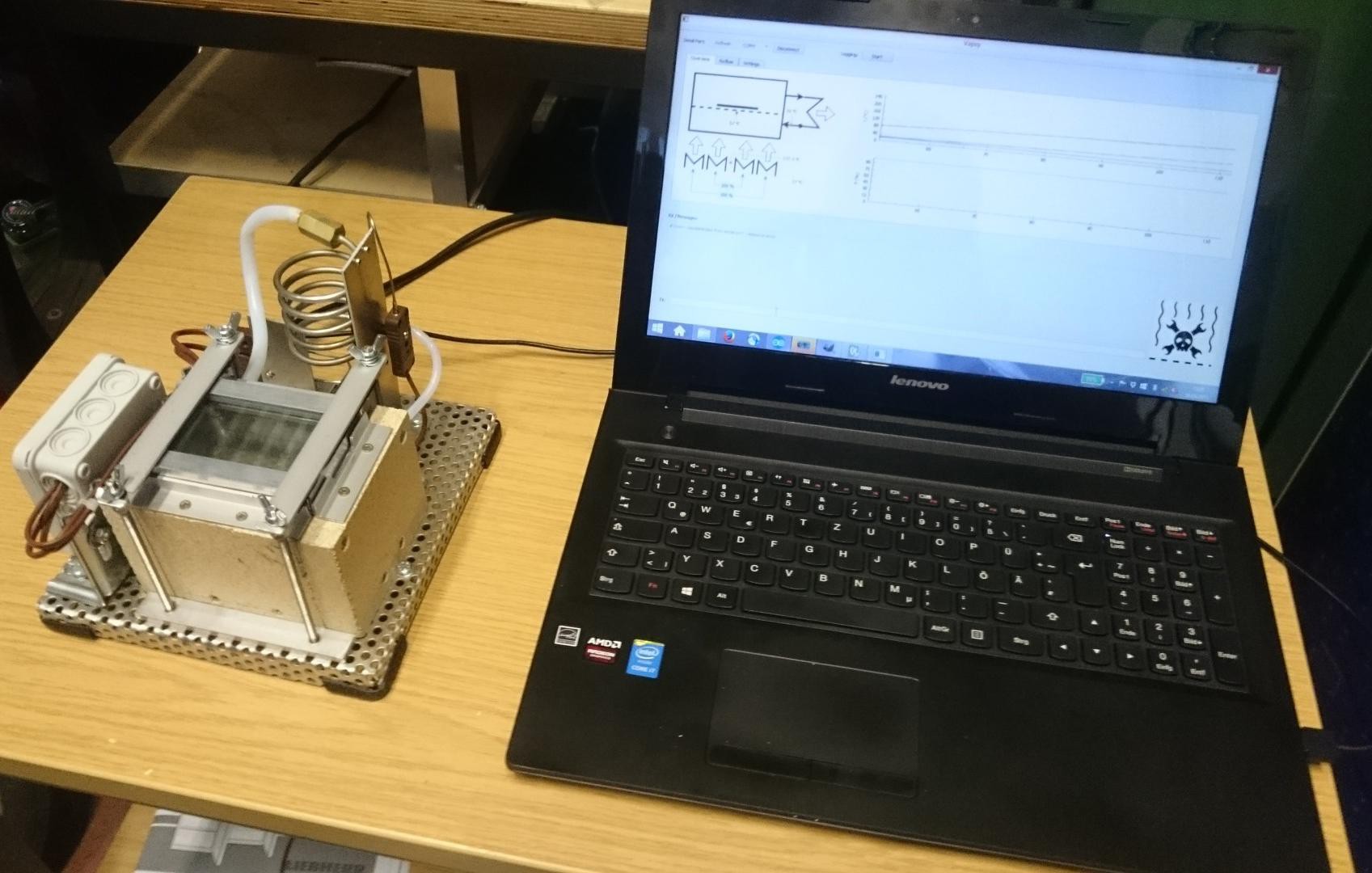

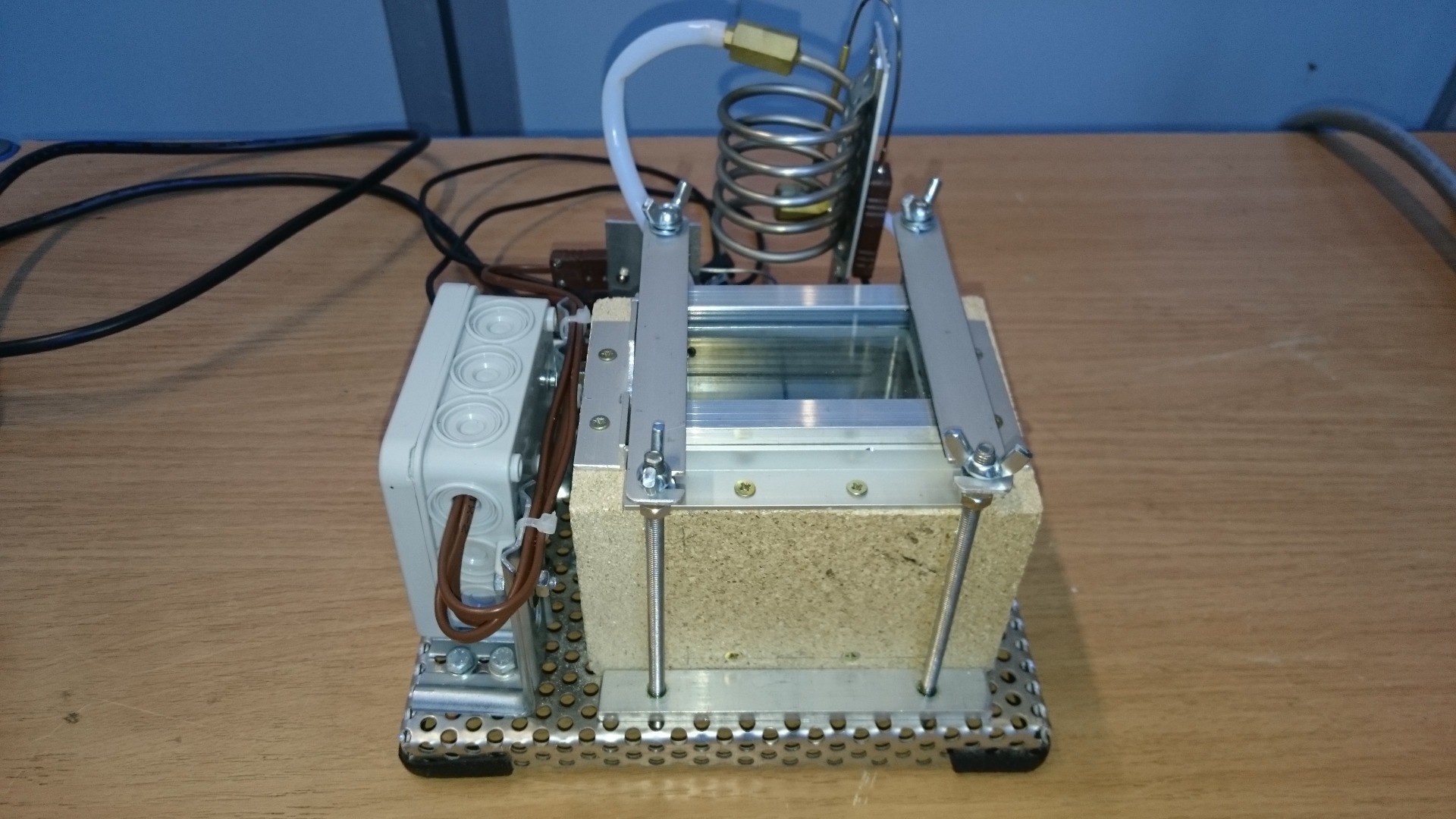

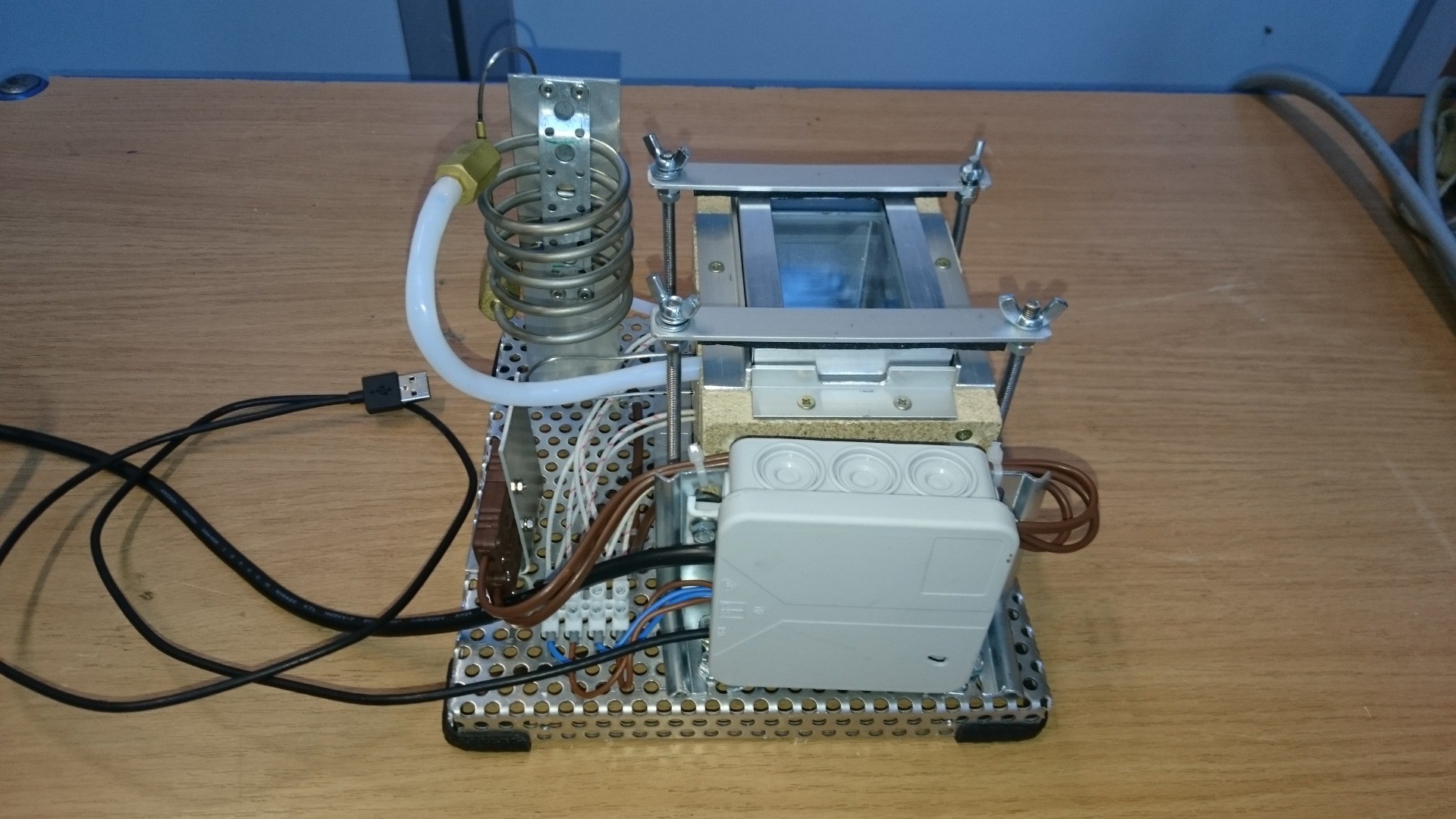

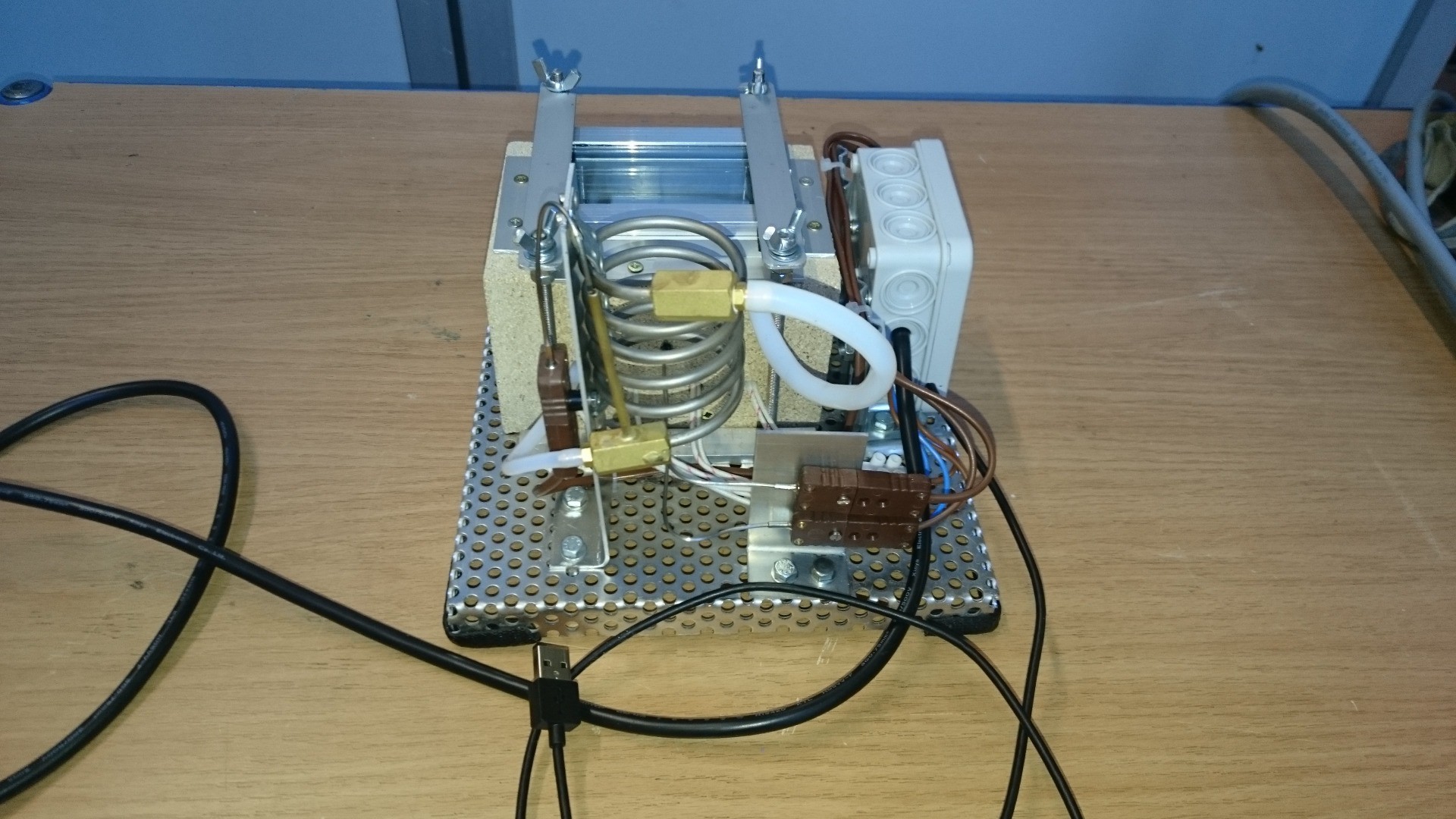

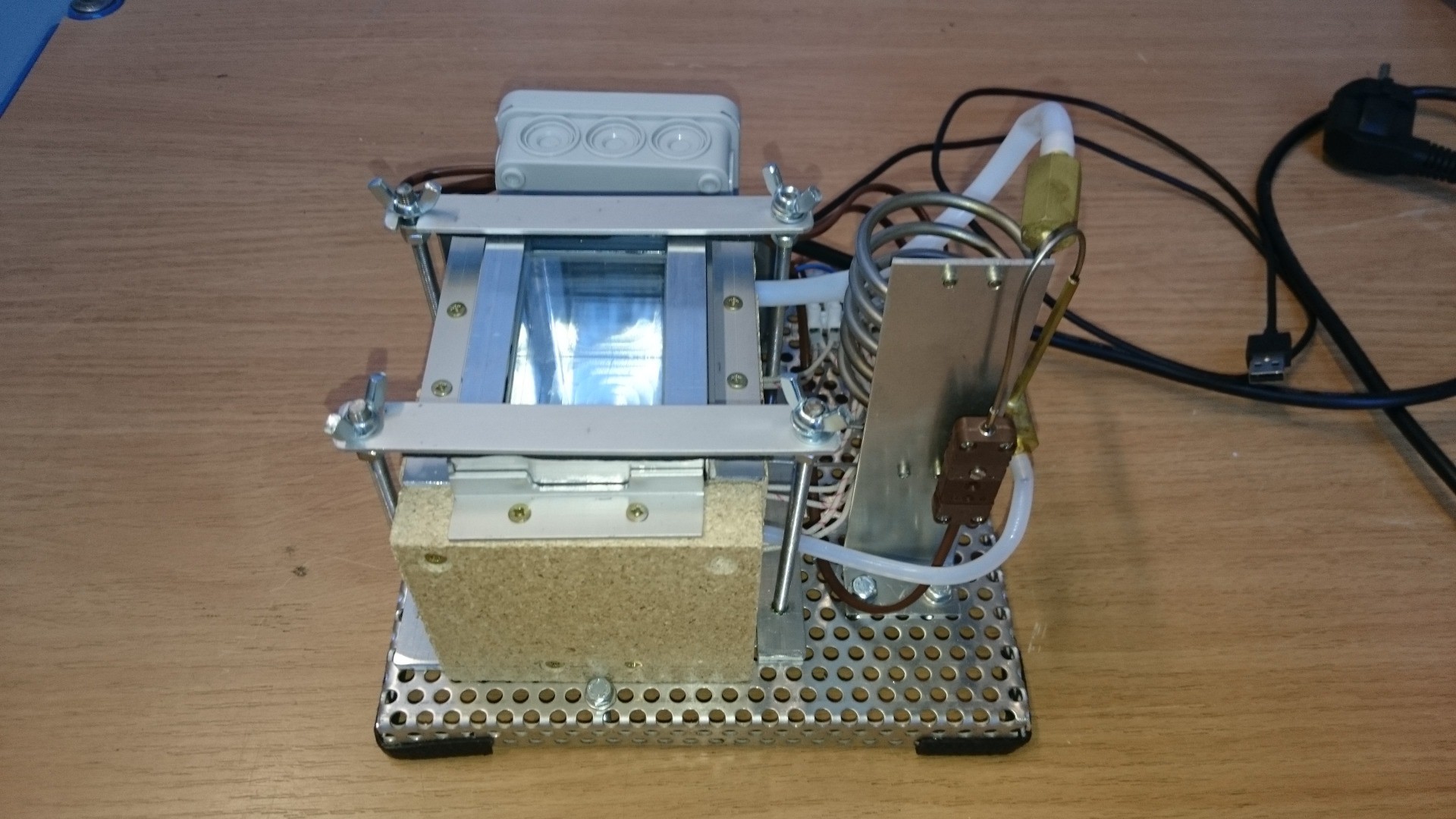

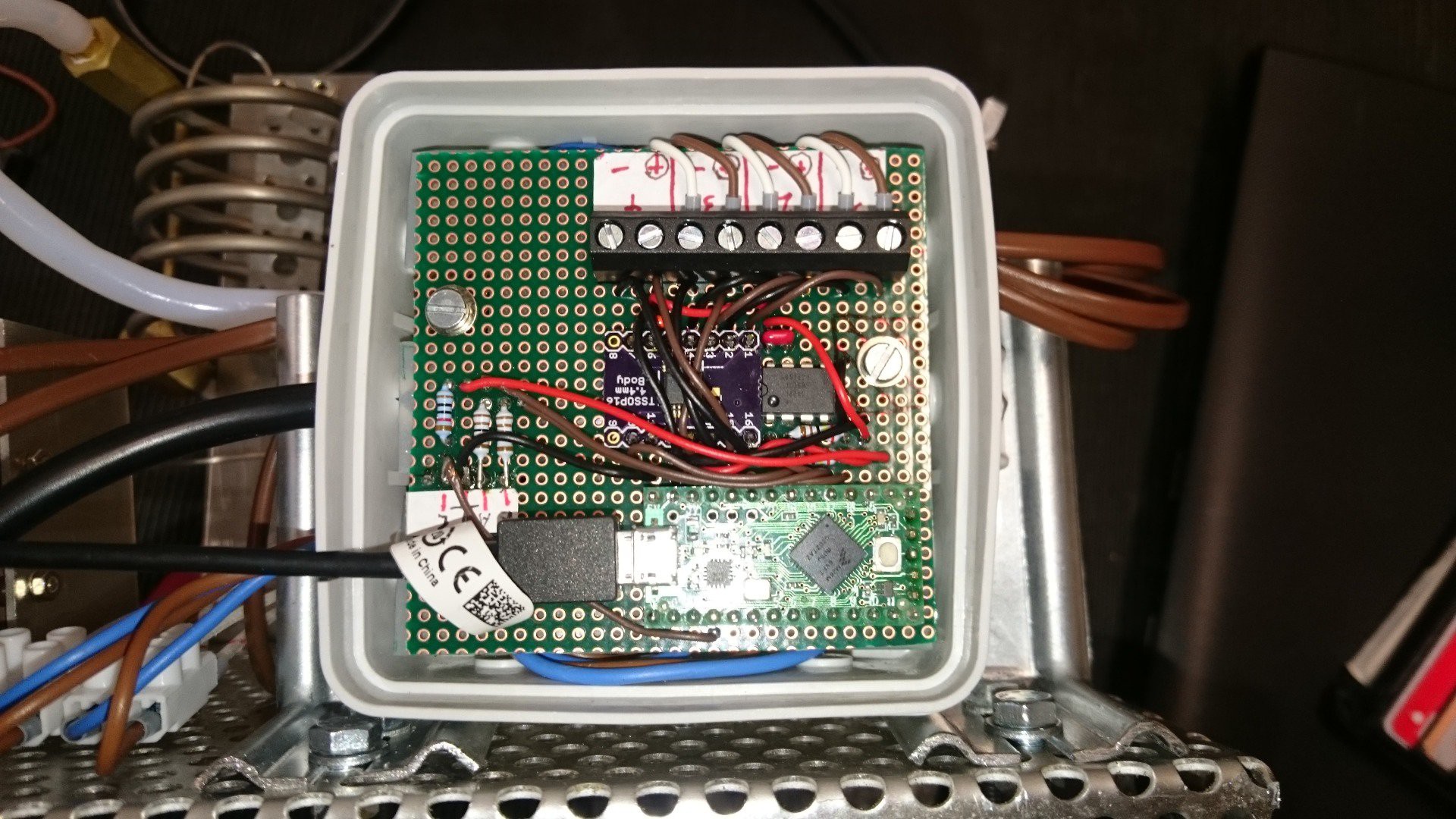

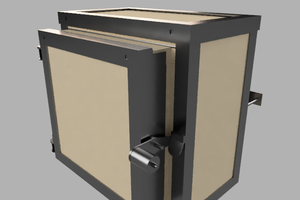

Final assembly with lid, tubes between chiller and chamber, and electronics box:

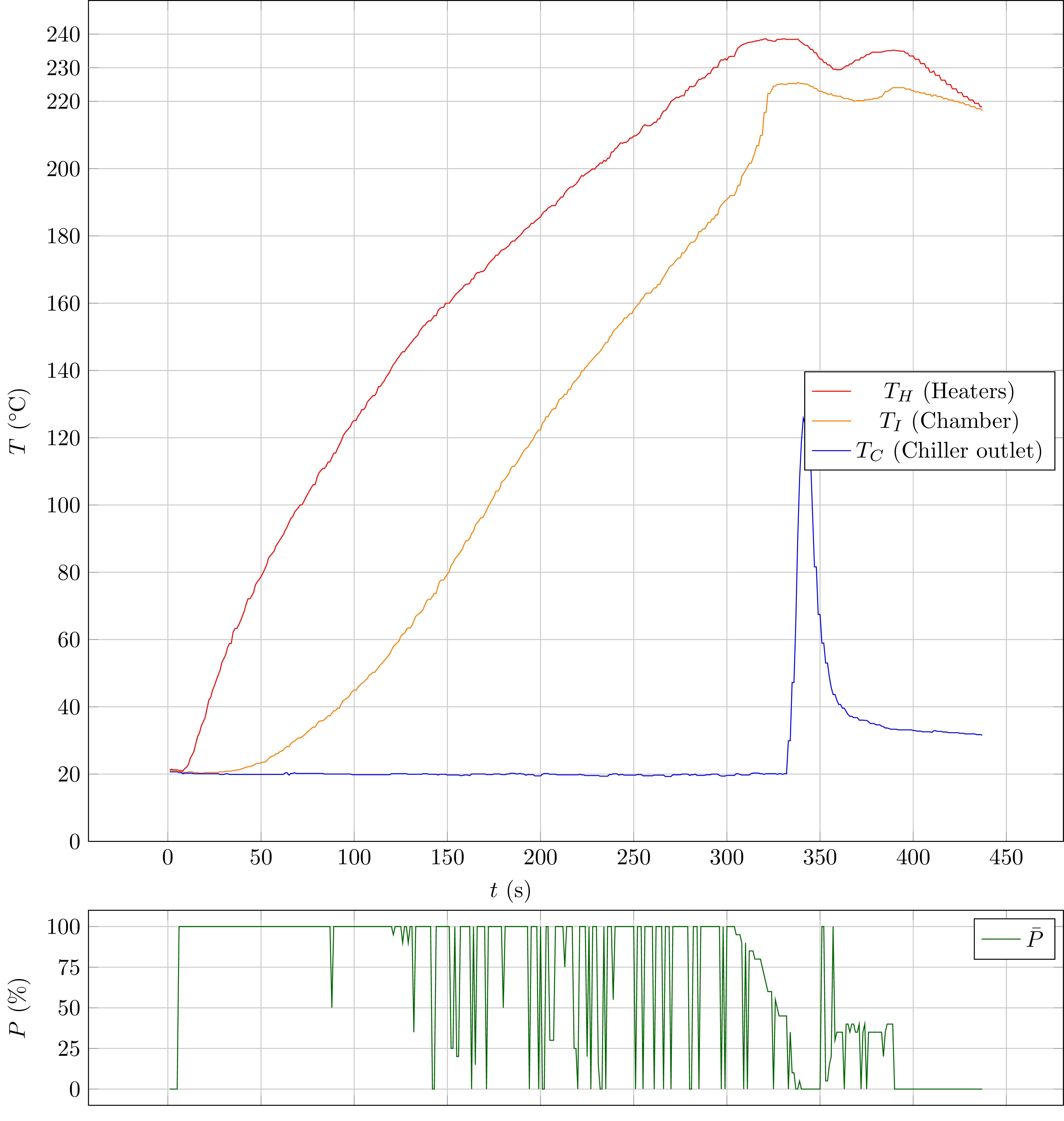

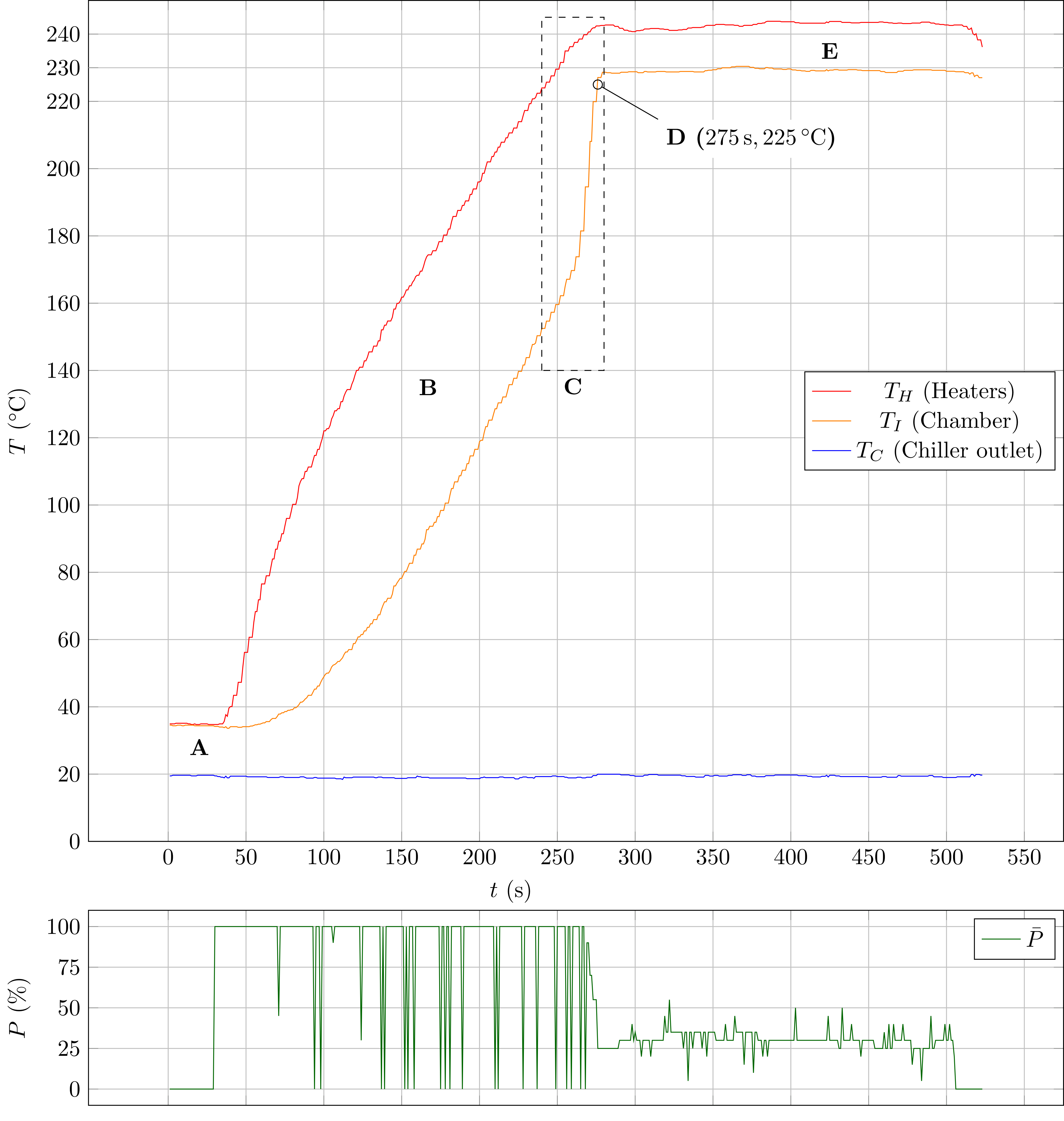

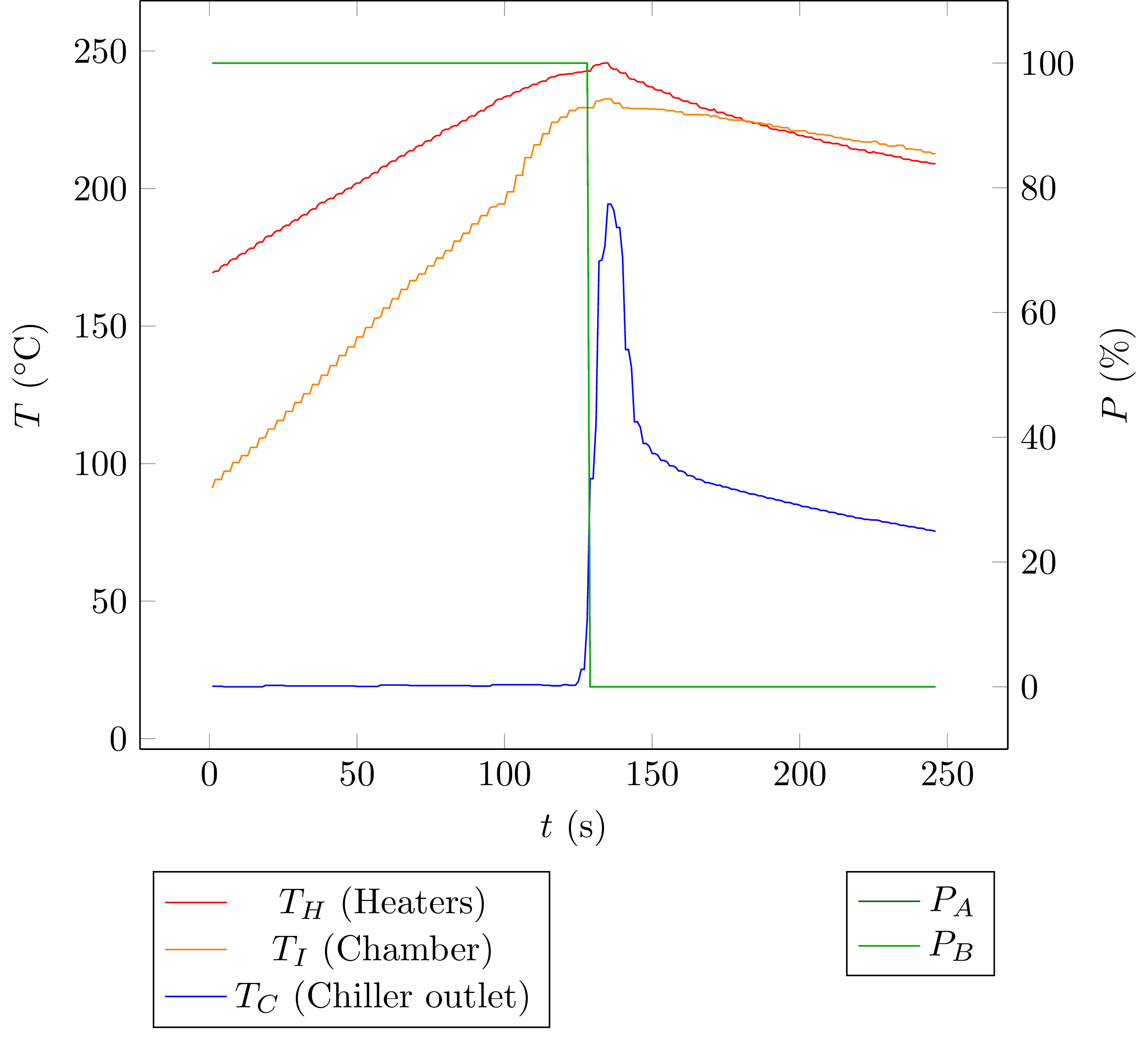

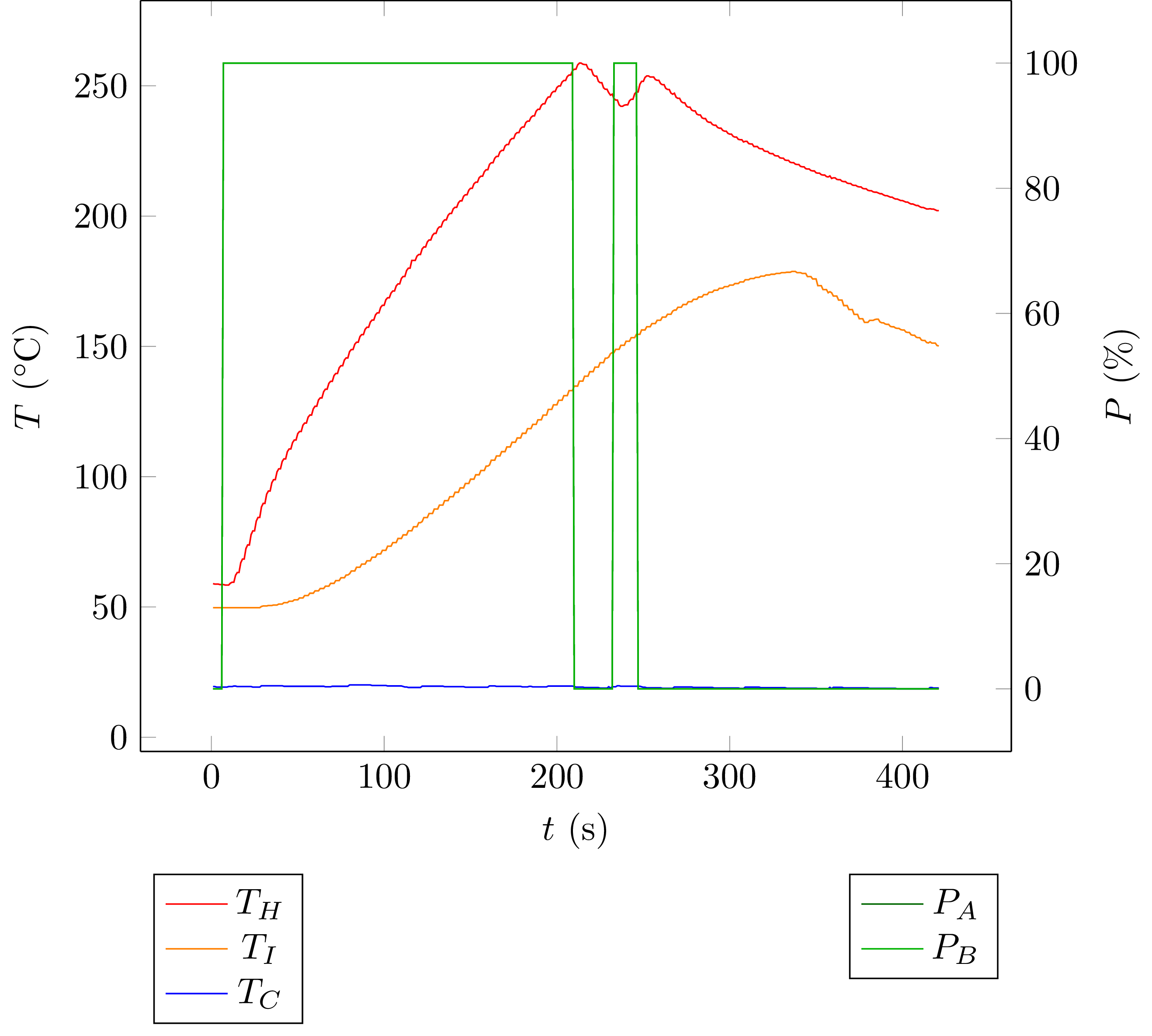

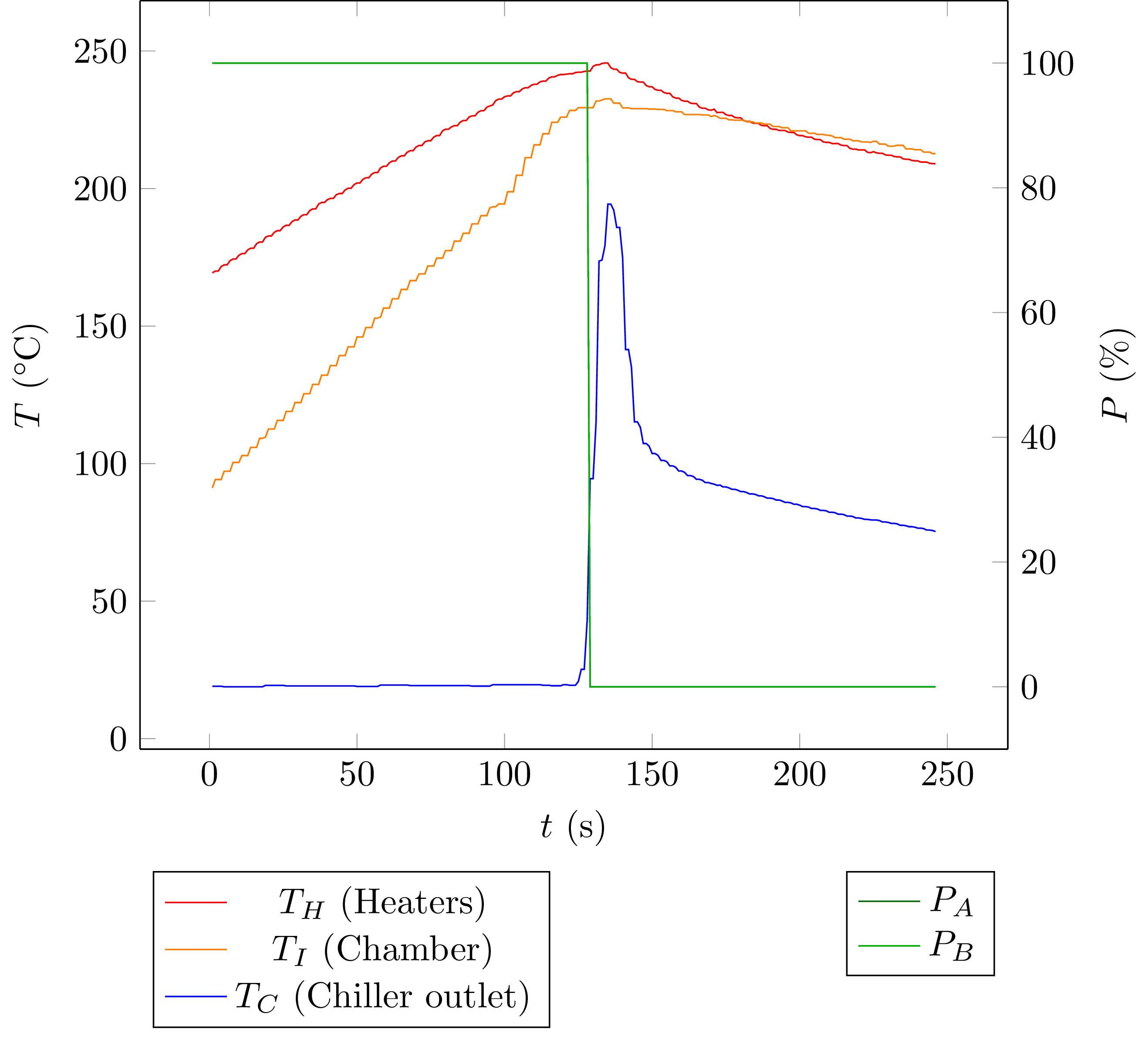

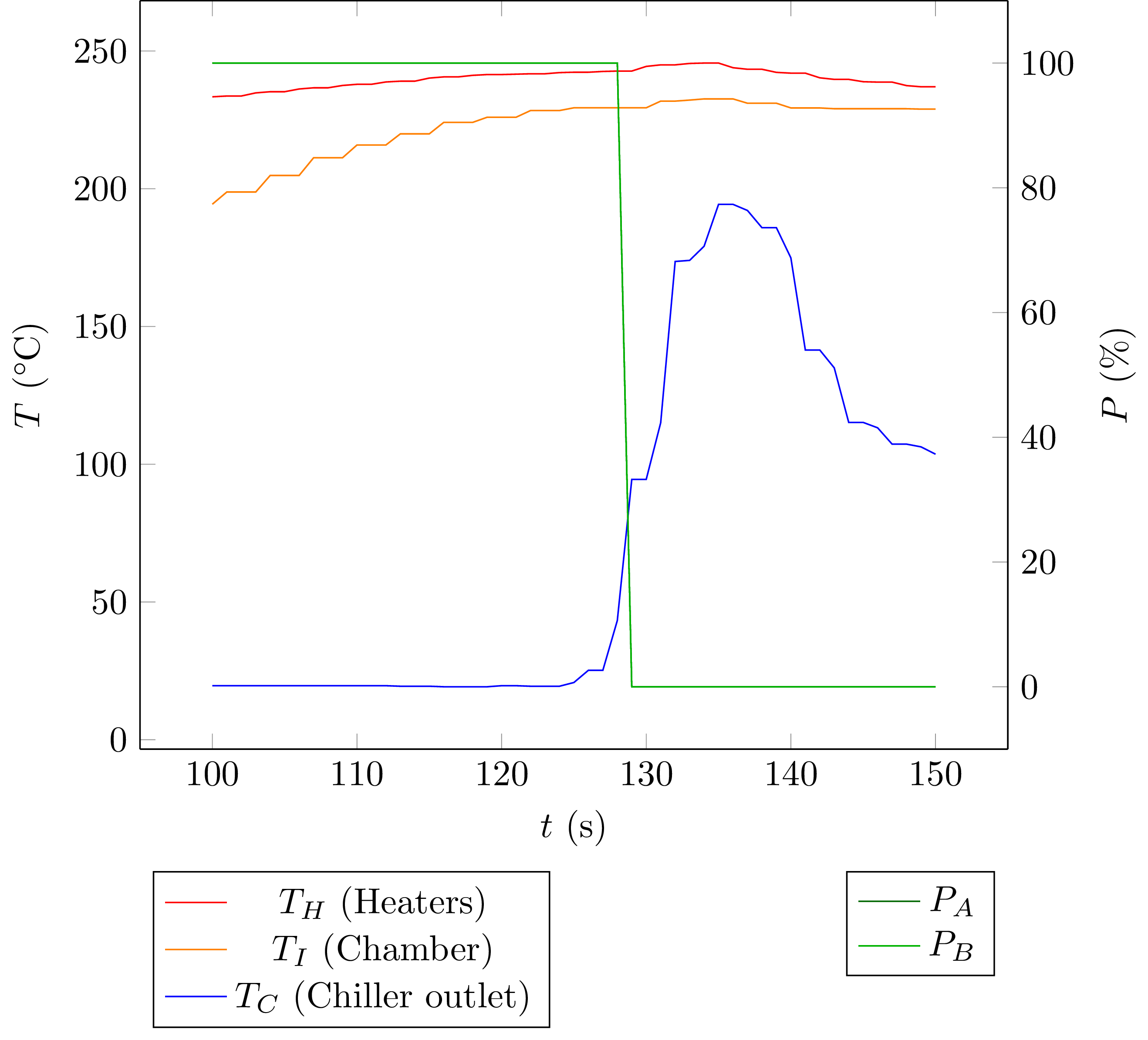

While galden evaporates, the chiller has to dissipate the amount of heat that was needed to evaporate the galden. While that is the case, the oven has a cozy reflow temperature that matches the evaporation temperature of the galden.

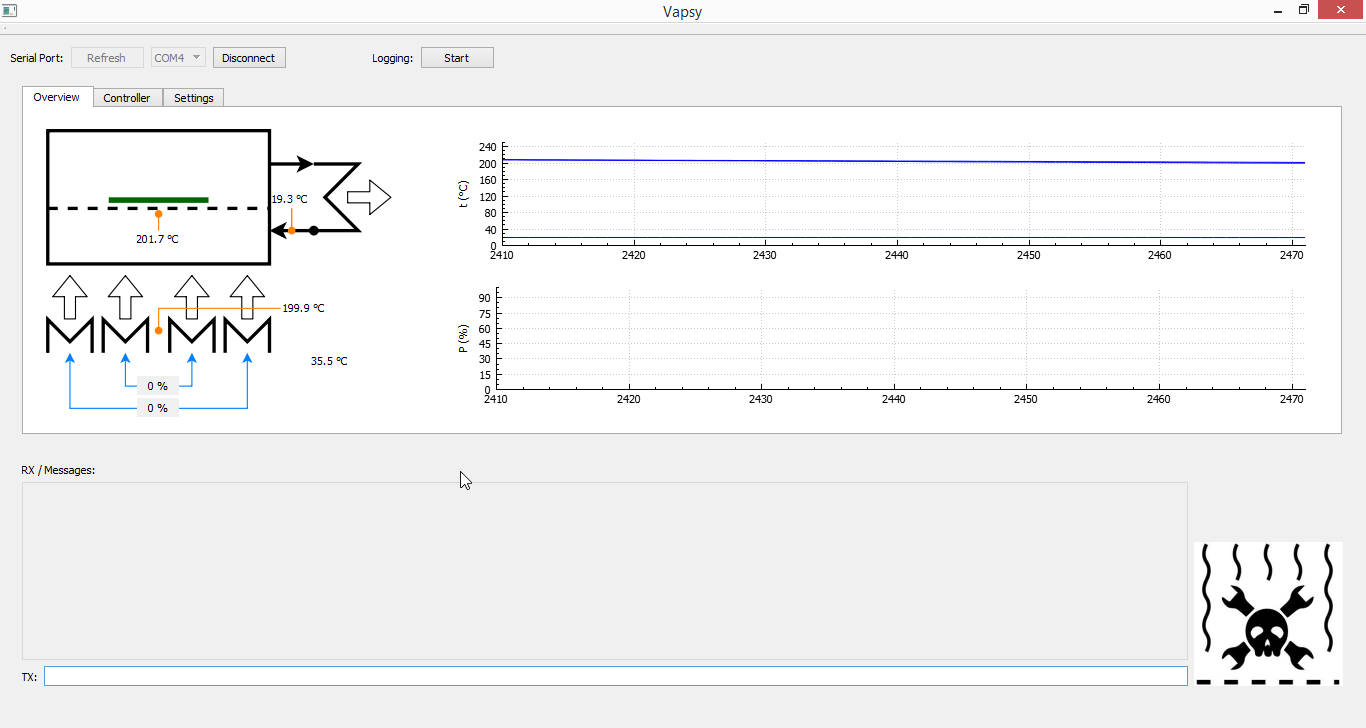

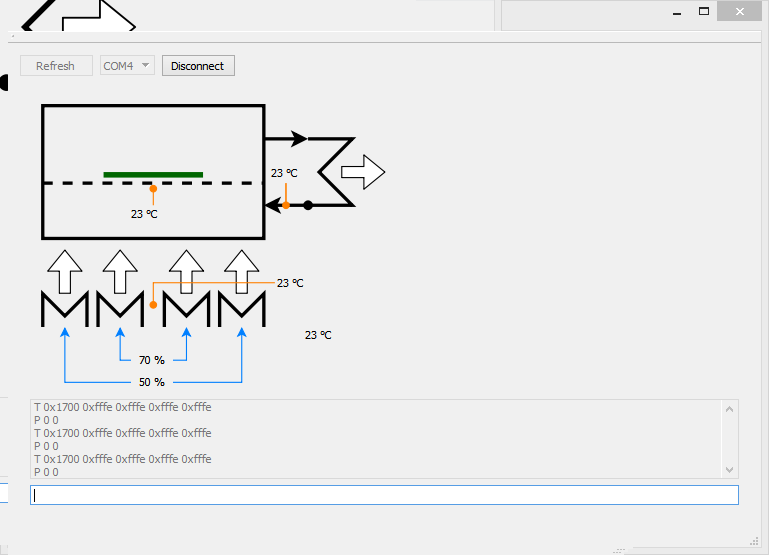

Of course, I also needed a GUI. I chose Qt for that because it now has a serial port class, which makes the code quite portable. It's not finished yet, but it will eventually end up on github. Here's a screenshot of an earlier version:

It turned out that the oven doesn't exactly work as intended, but it does solder PCBs. Check out the project logs for details on every step of the build!

Christoph

Christoph

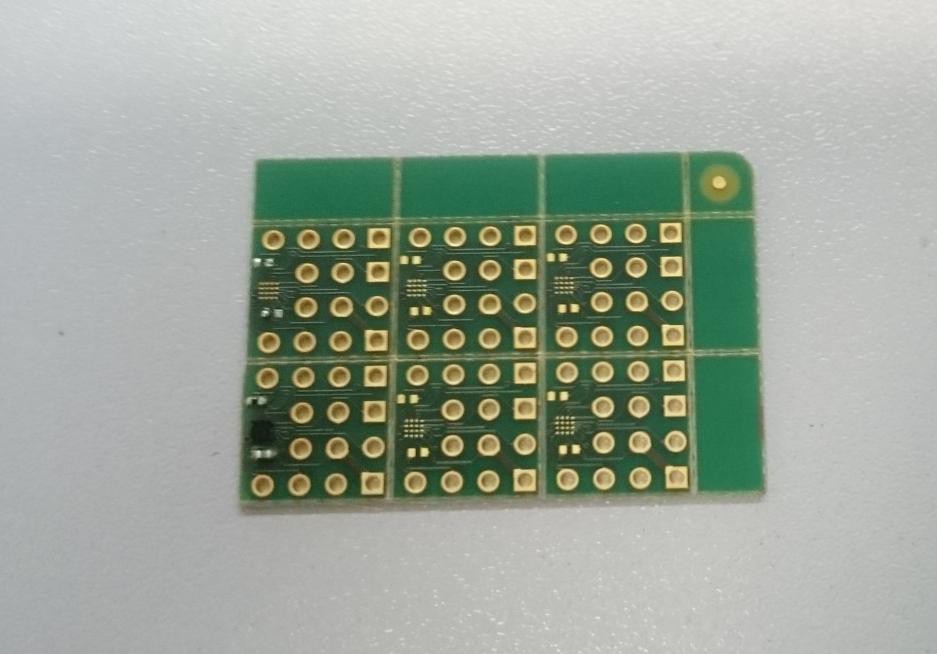

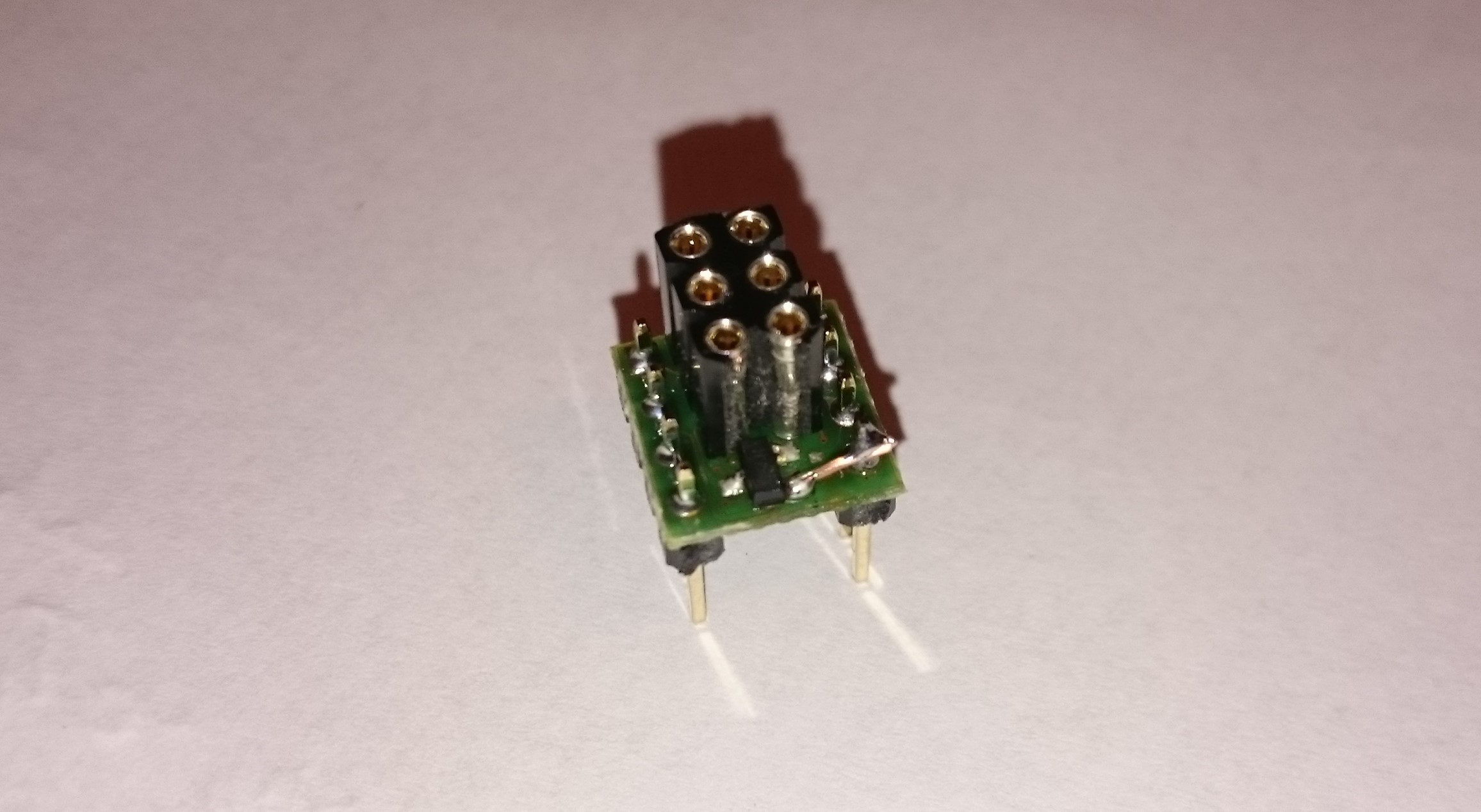

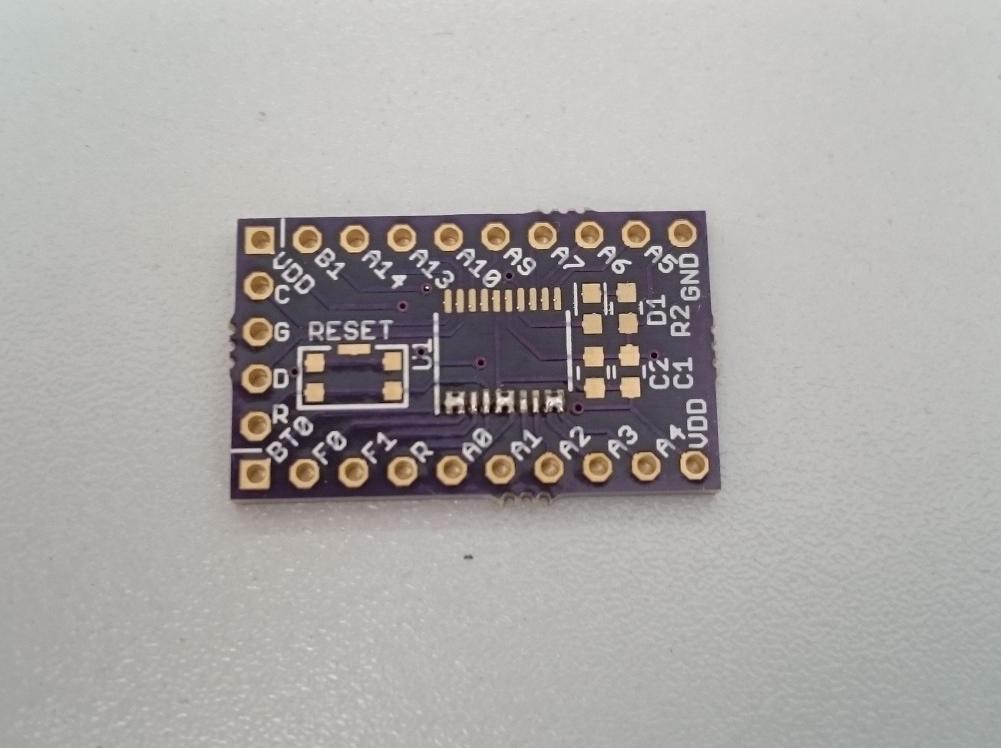

Until now the only consequence of this is that I had to turn the pcb around, so the pins are mirrored.

Until now the only consequence of this is that I had to turn the pcb around, so the pins are mirrored.

Gerriko IO

Gerriko IO

Well executed project and a great writeup!