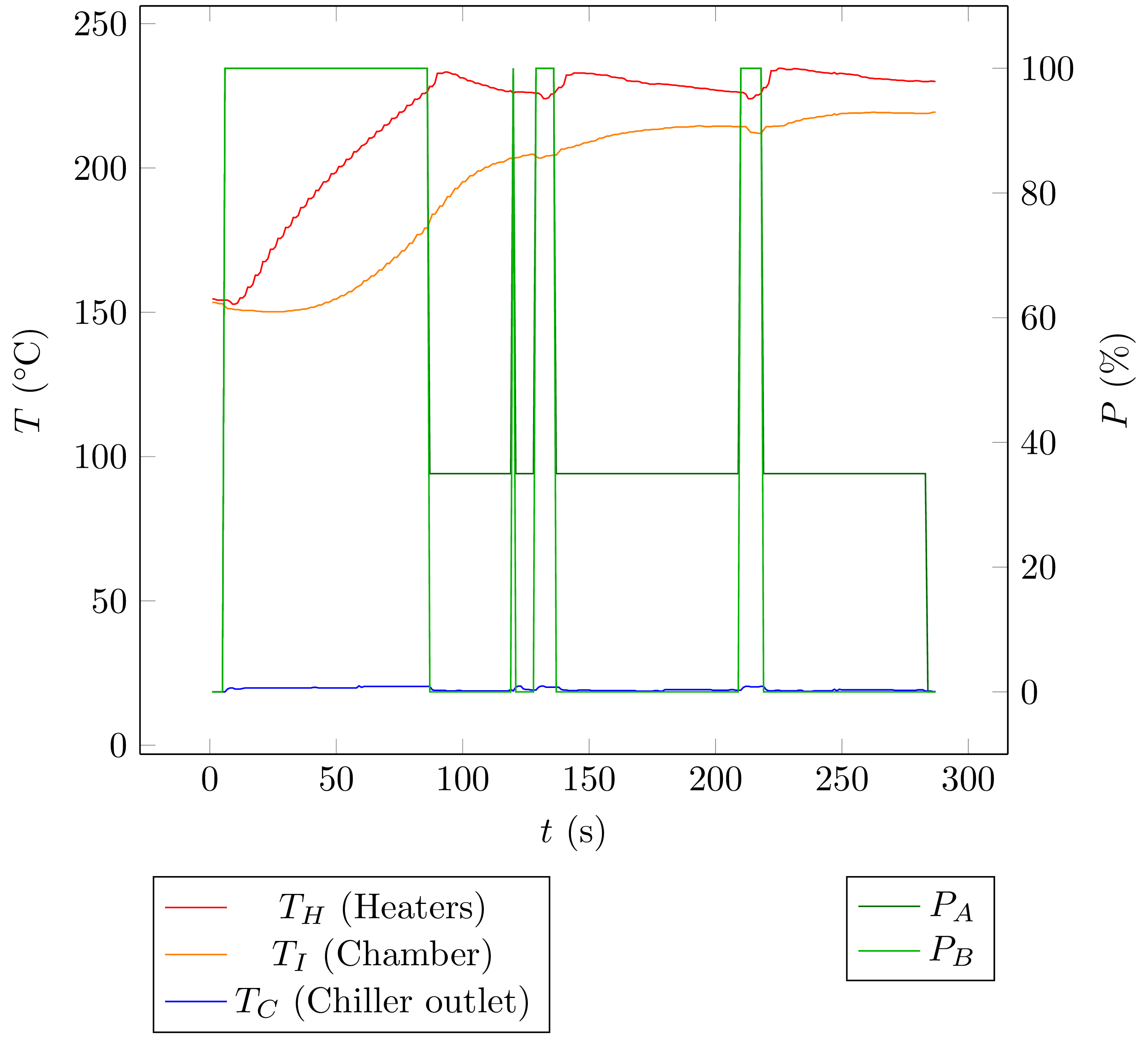

Some more threshold temperature checks were implemented (my plan was different but I had an error in the implementation. The power should be higher, and these are the actual values):

- limit power to 70 W (17.5 %) when the heaters are above 225 °C

- limit power to 40 W (10 %) when the chiller outlet is above 70 °C

- cut power when the chiller outlet is above 100 °C

This is the result:

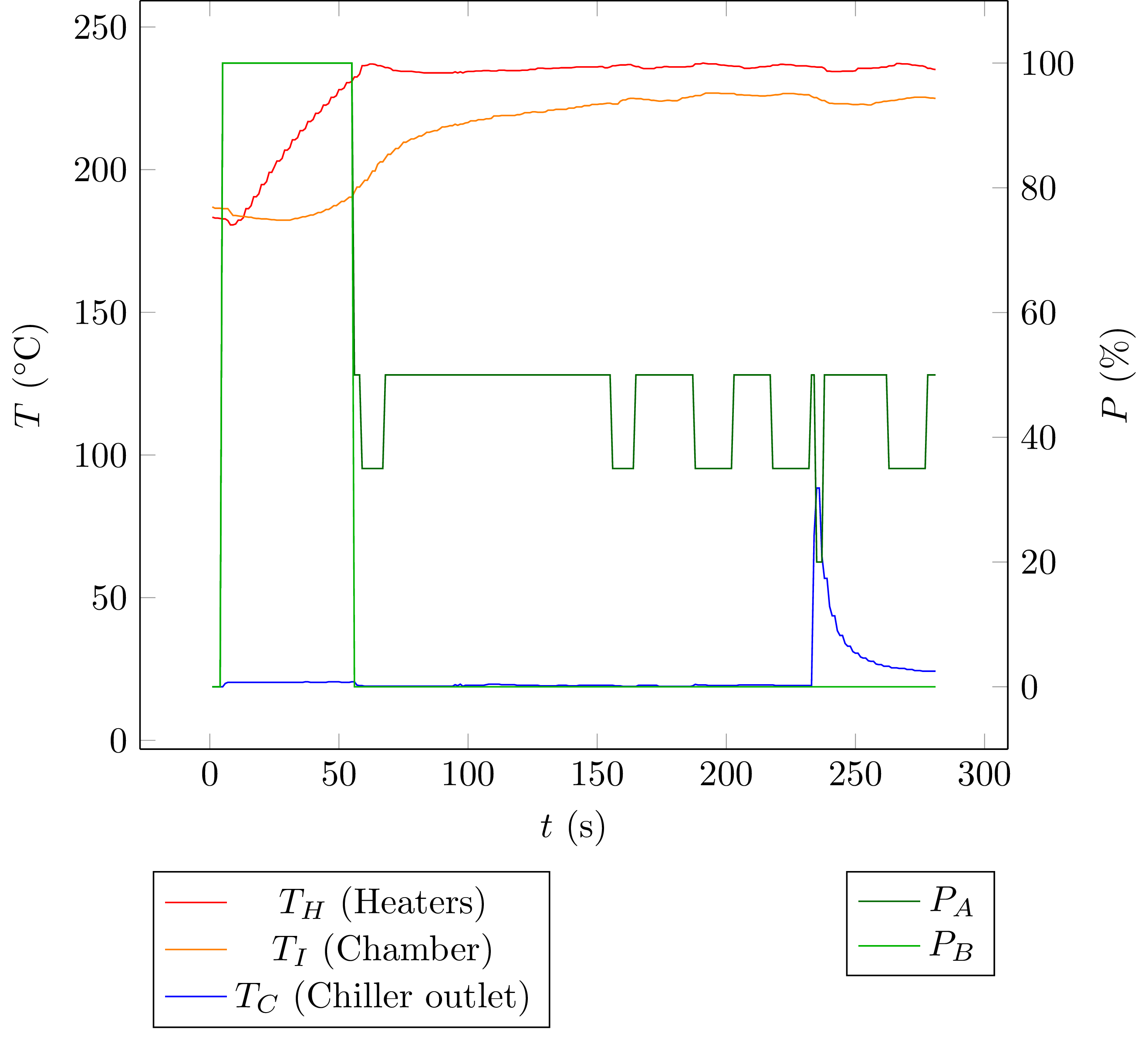

So I changed this a bit:

- limit power to 100 W (25 %) when the heaters are above 230 °C

- limit power to 70 W (17.5 %) when the heaters are above 235 °C

- limit power to 40 W (10 %) when the chiller outler is above 70 °C

- cut power when the chiller outlet is above 100 °C

Things were a bit different now:

Now there's saturated vapor in the chamber at about t = 220 s, and a short while later the chiller outlet temperature jumps to some 90 °C. This jump could be anticipated, because some evaporated galden condensed in the chiller inlet tube, which has a short horizontal section just behind the chamber. A galden drop built up here, basically obstructing the outlet until too much galden evaporated and suddenly a lot of it got into the chiller.

The chiller reacts quickly to the increased galden mass flow, and also shows fast recovery from such a "flush".

Next:

- improve tube geometry to have less galden being collected in there. This is annoying because the teflon tube is so hard to get into shape;

- fix power setting algorithm,

- write a P- or PI-controller for the heating up state, and one for the saturated vapor state.

Christoph

Christoph

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.