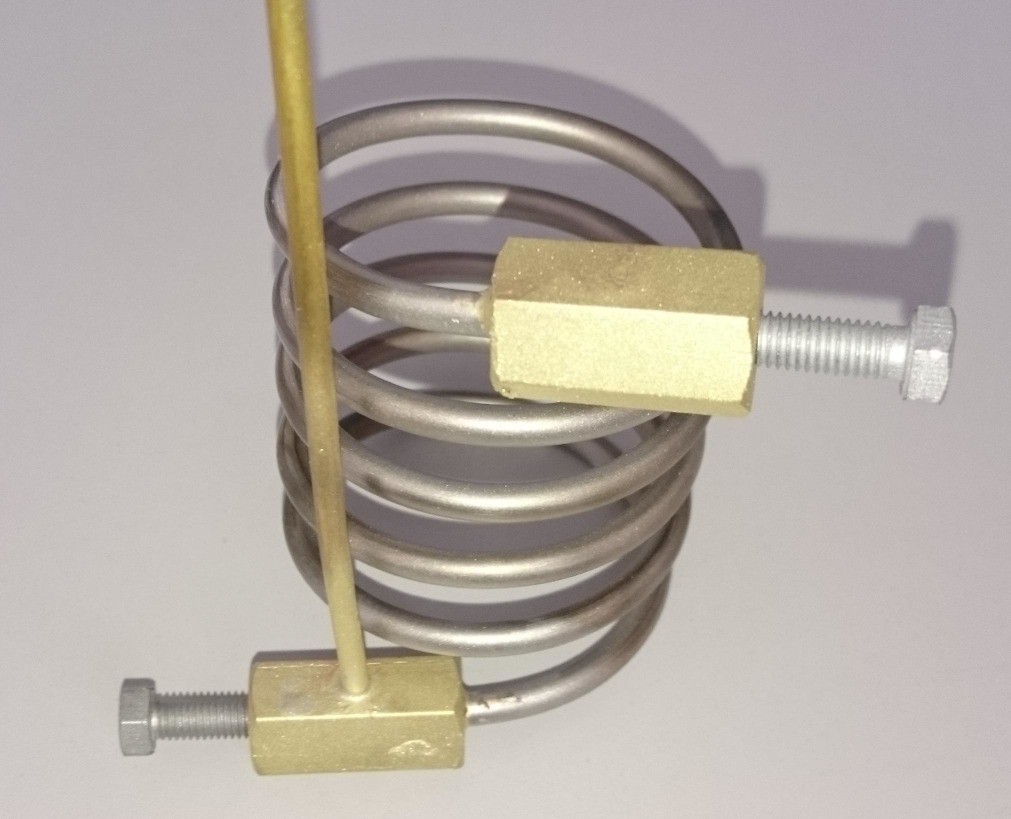

Chiller and fittings brazed with silver solder (650 °C, acethylene/oxygen flame) and sandblasted:

Turned out nicer than expected!

The screws are just there to prevent sand from getting into the chiller during sandblasting. The vertical pipe will be cut back later when I know how long I need it.

Note: you can also use a simple torch for brazing if your parts are small. It might take a bit longer, though. You can also use solder with a higher silver content, which melts at lower temperatures.

Christoph

Christoph

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Wow, that looks fantastic!! Nice brazing work!

Are you sure? yes | no