The last design wasn't working so well, mainly due to the opening/closing servo part of the design effecting the precision of the throw, so I decided to change it up completely and create a design where the hand stays upright the entire time so that I don't have to open/close the hand, but first, I decided to change the surface of the ramp. The acrylic sheet broke anyway, so I decided to find some other material.

The material used on my ultimaker2 3d printer frame was super smooth. I found out that it is called dibond. I love this material. It's basically plastic sandwiched between two sheets of painted aluminum. Here is the result:

For the redesign of the hand, I figured that I would add a link to a passively rotating part (I'm not sure the correct terminology here) to help keep the hand upright. As it turns out, that is not sufficient because there are two angles where the system ends up in a gimbal lock situation and the passive rotation ends up switching direction. I ended up fixing that by adding a second link. Here is a video showing this problem:

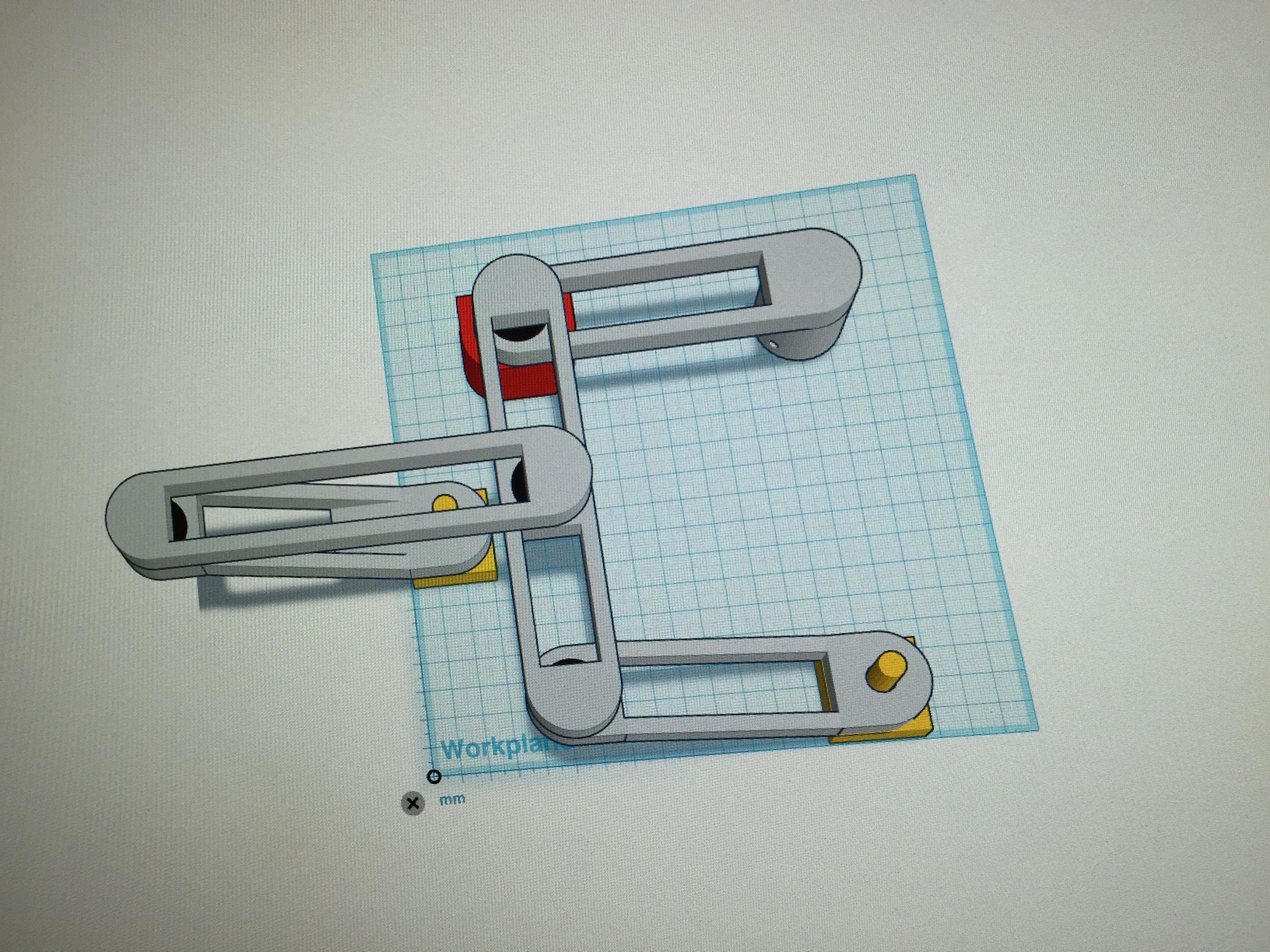

Here is the initial design:

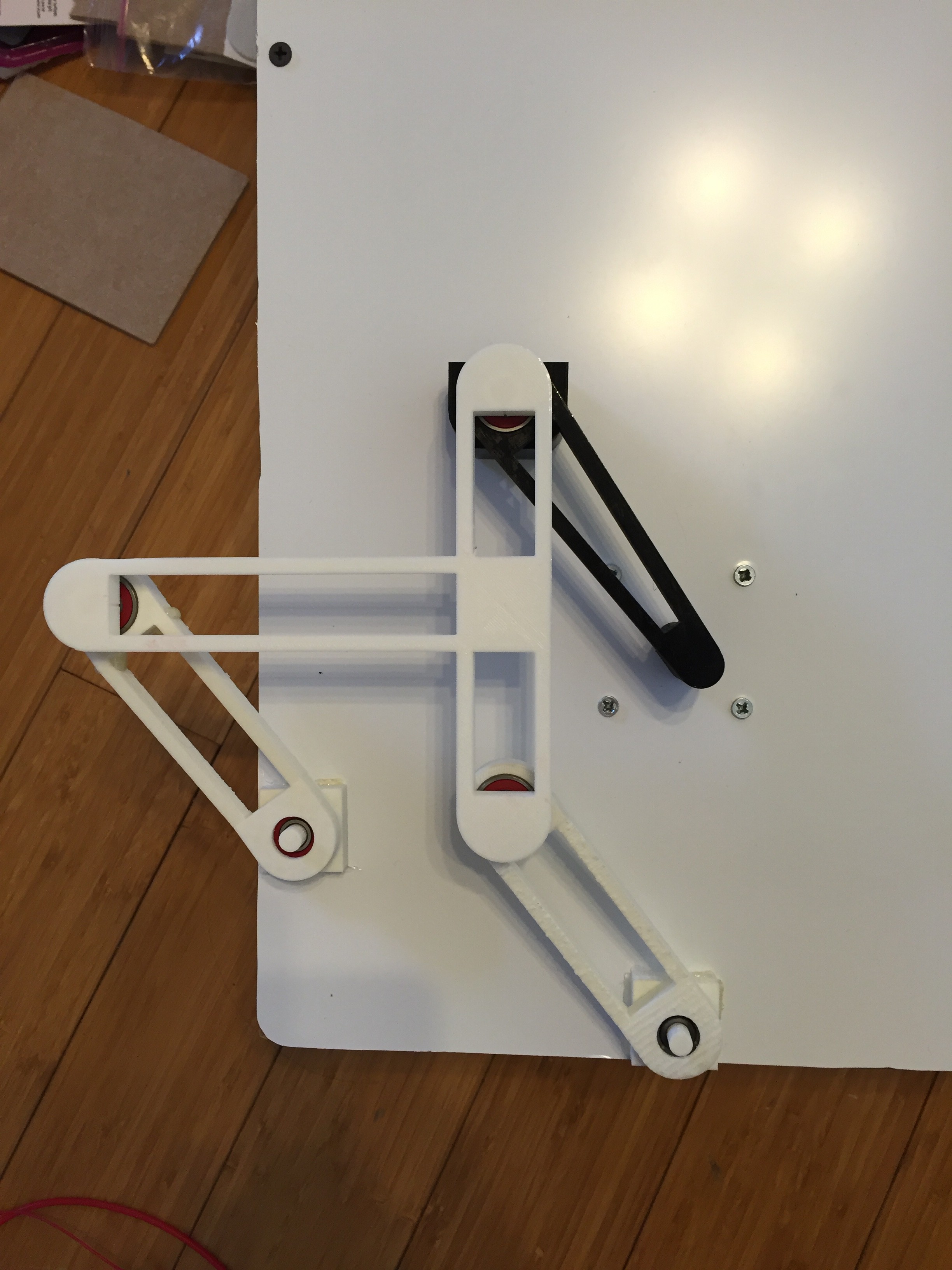

And the printed version (I used Bones Reds skateboard bearings from the nearest skate shop for the joints):

Nathan Peterson

Nathan Peterson

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.