Now that I have a milling machine I can improve my milling machine.

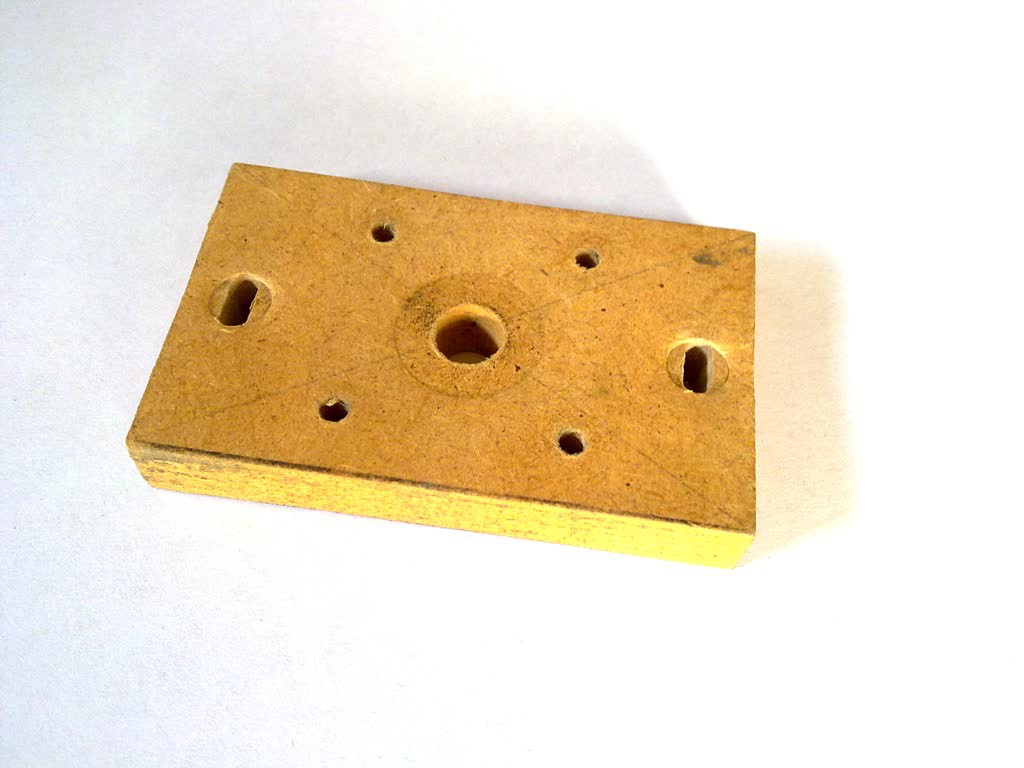

The original MDF motor brackets that I made were pretty crude. The slots that I cut with a Dremel by hand took ages to do and I couldn't think of a reasonable way to cut the 2mm deep circular pocket to take the step on the mounting face of the motor. The slots ended up shorter than planned and the pocket got omitted altogether. Here is a photo of one I just removed.

Note also the compression damage to the MDF, especially where the M4 bolts have gone through the slots. I'm in the process now of changing every washer that lies against MDF to a penny washer. That would have been a good idea from the start.

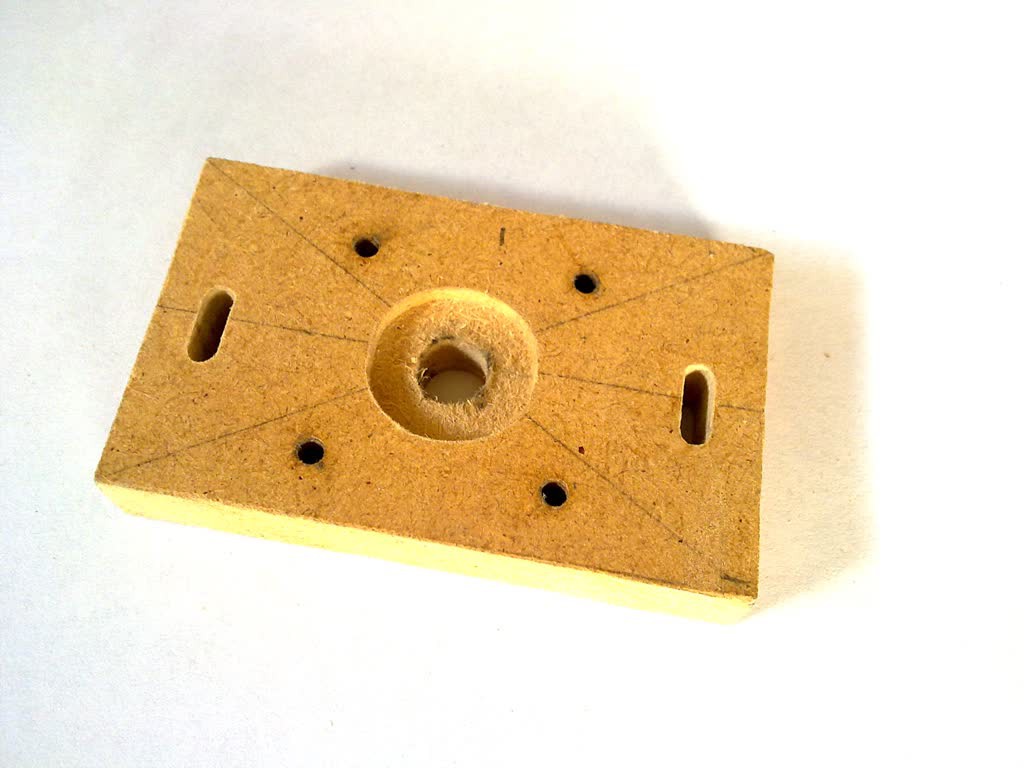

I have now made and fitted new brackets with longer slots and a recessed pocket to better fit the motor.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.