For the past couple of days I've been working to adapt the motor to the transmission. This is a fun process and it's going really smoothly. I'm designing the adapter plate with cardboard for now but hope to put all of the measurements in solidworks and CNC a plastic prototype to see if everything checks out before going to aluminum.

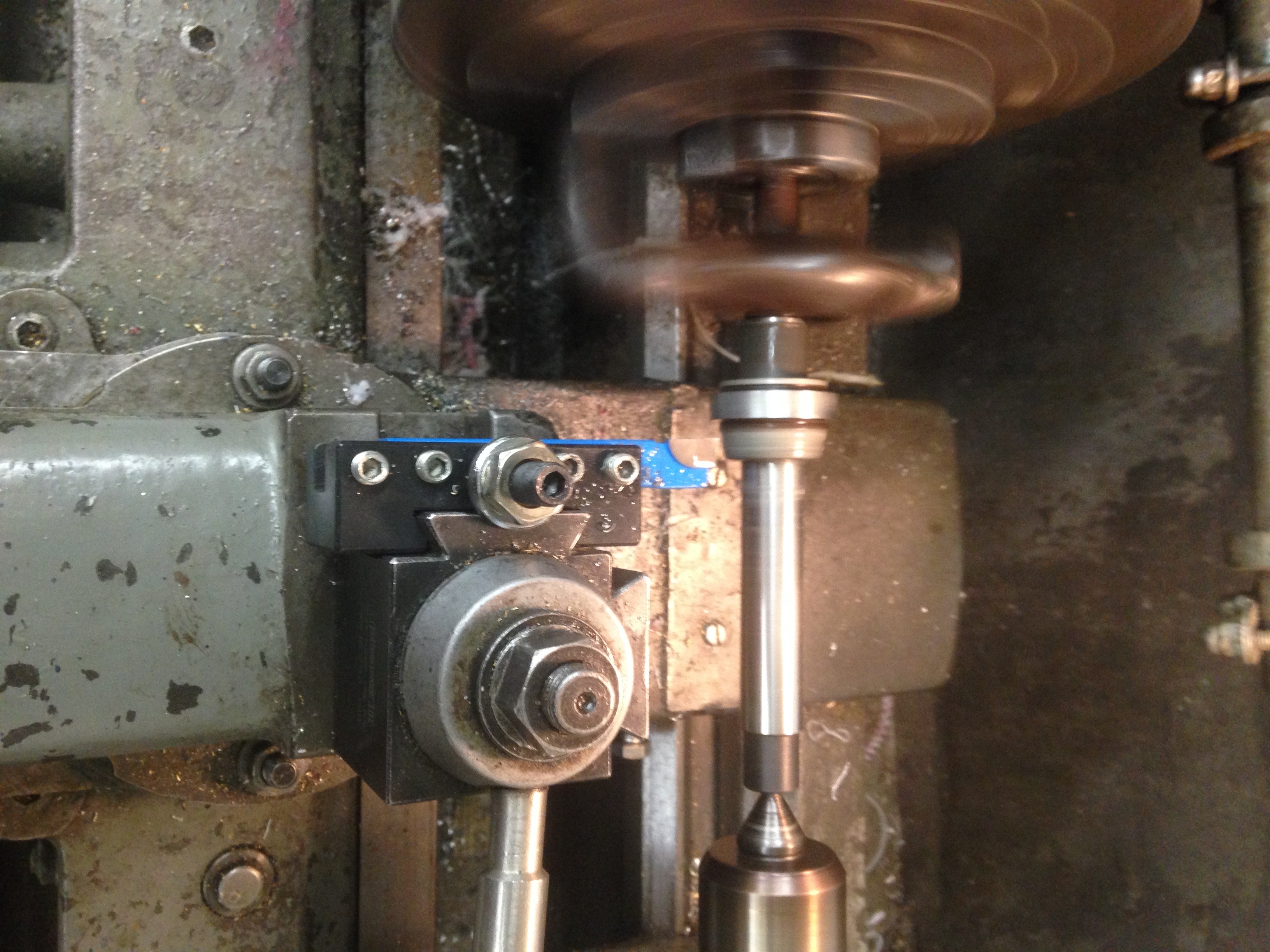

Adapting the motor shaft to the transmission is also going well, but I'm not %100 sure that I'm doing it the best way. Yesterday I cut the splined center piece out of the original clutch plate. This has the correct splines for the transmission of course. I turned it down to the same diameter as the motor shaft keeping it concentric around the splines. I'm not sure what the best course of action for attaching these two shafts is though. Any suggestions?

Adam Curtis

Adam Curtis

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.