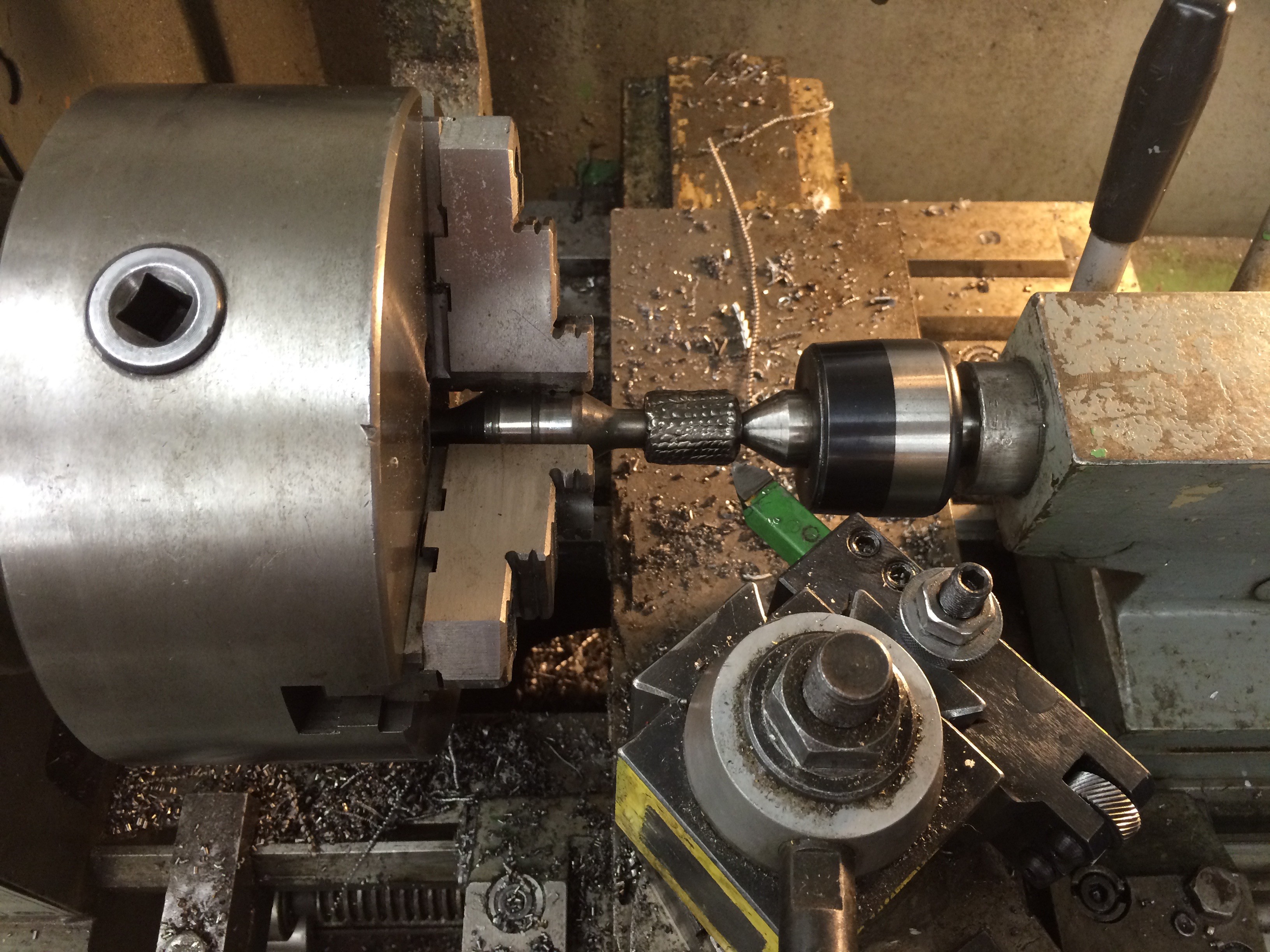

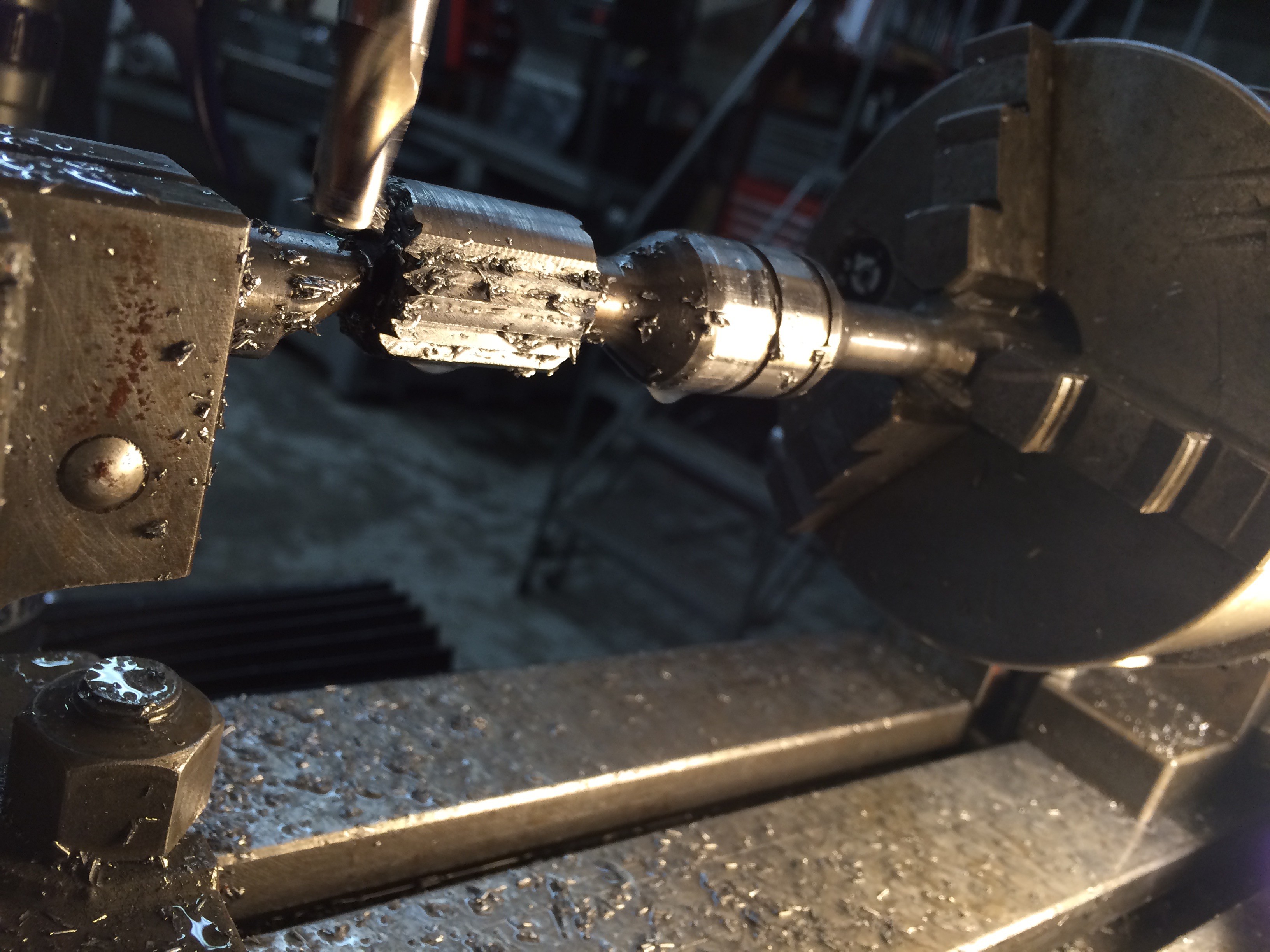

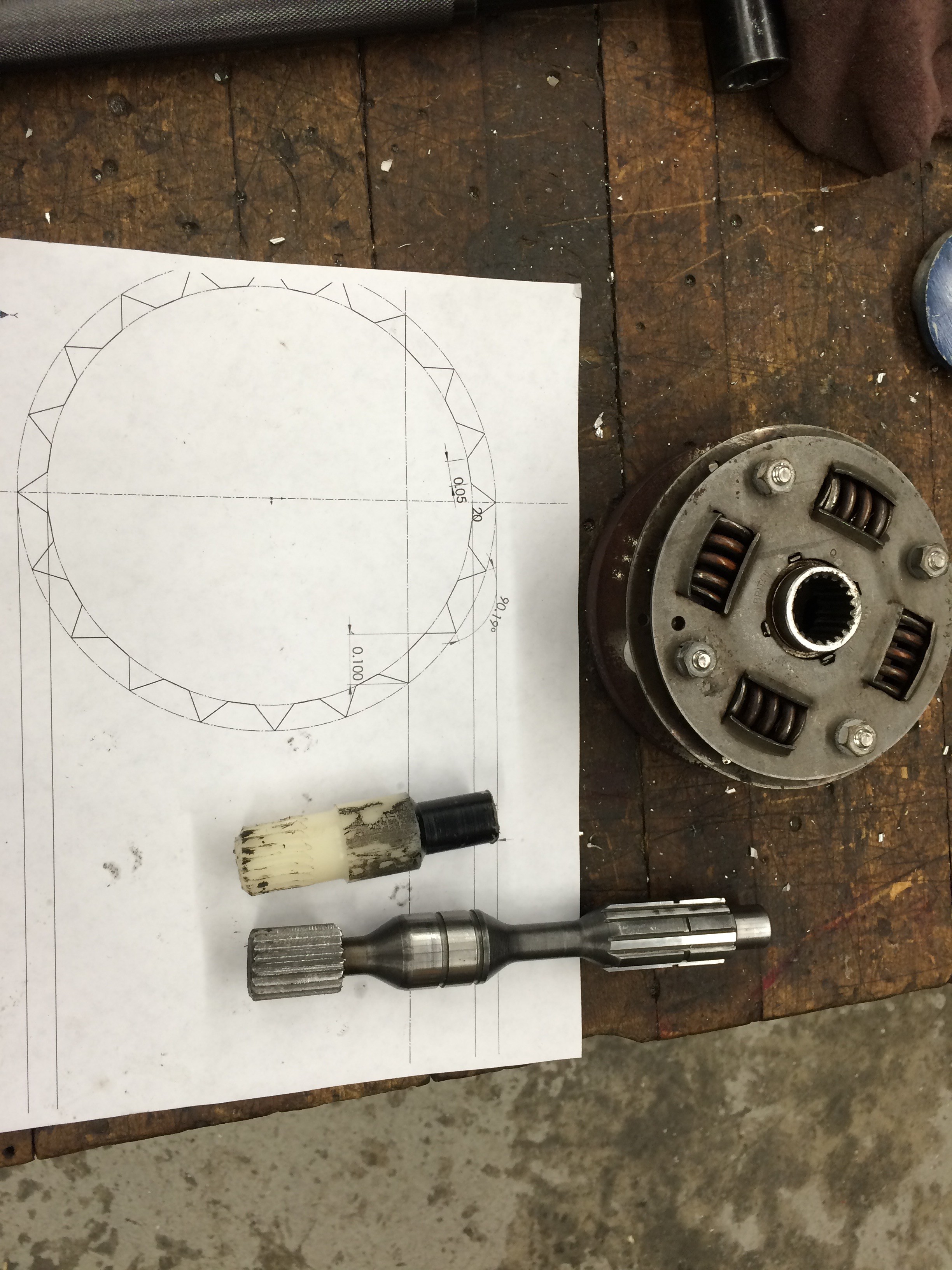

Along with working on my battery pack I machined the splines onto my transmission input shaft today.

I'm not 100% sure this will hold up to abuses but it will get me going until I can afford to have a rod of chromoly CNCed into a permanent solution.

After drawing up the splines that I needed to make to fit my adapter coupling I found that the angle between splines was a perfect 90 so I just used a flat end mill and cut with the corner at just the right height and depth while my shaft was in the indexing head on the Bridgeport table. There were conveniently 20 splines and the indexing head is a 40 to 1 ration so I'd cut a spline, swing the arm twice and repeat.

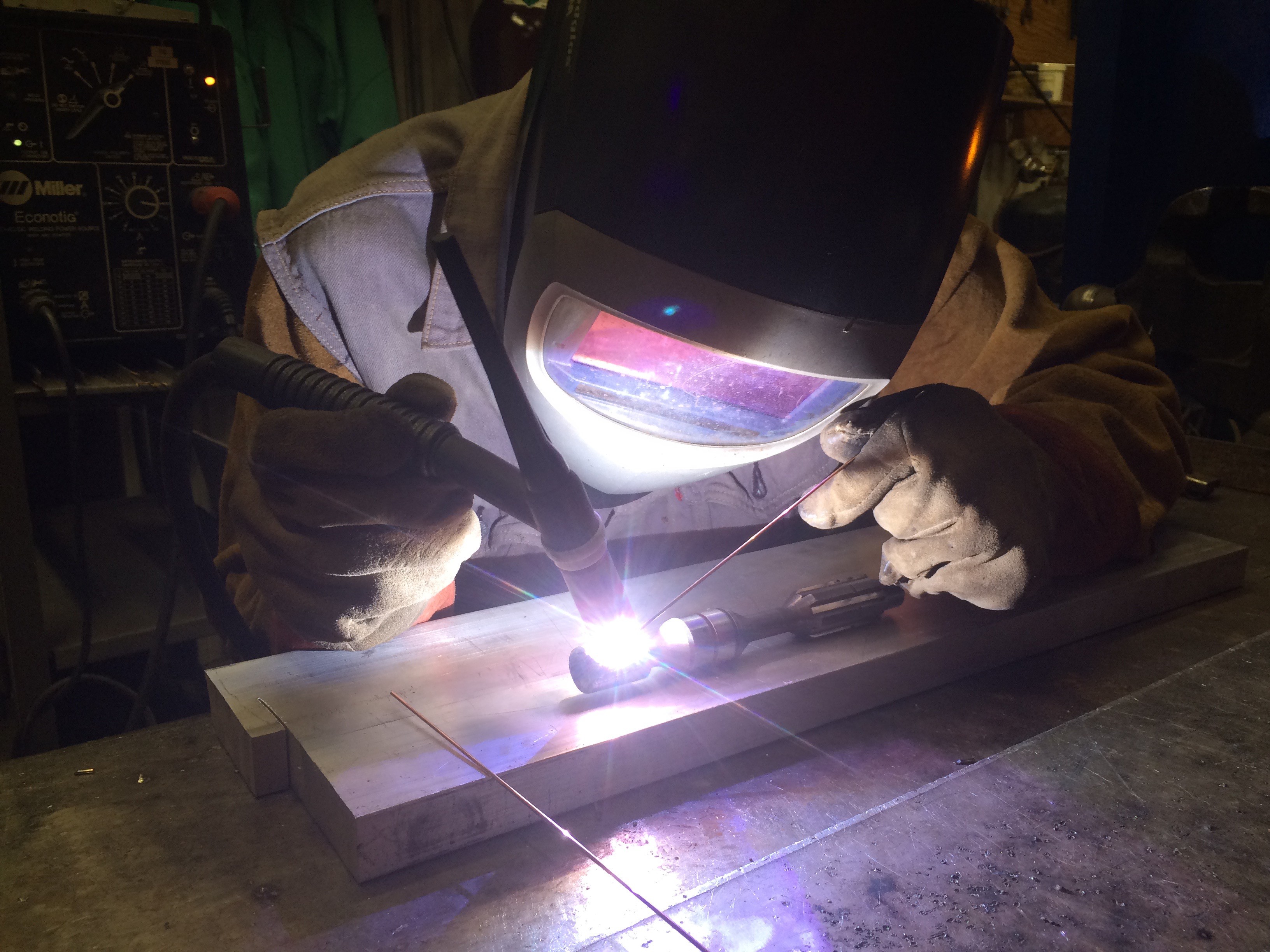

I cut these splines into metal that my friend and welder protoge Rhett Courser laid onto the shaft with his magical TIG skills.

Here are pictures so you can understand what I'm talking about.

Adam Curtis

Adam Curtis

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.