I've created the plastic prototype of my motor to transmission adapter plate with rudimentary technology. I think I will CNC the next one on the mill. This time I worked slowly and accurately but there might need to be a little bit of revision before I make the final version in aluminum.

I'm working on designing a custom driveshaft to replace the input shaft of the transmission. This will cost a little bit more money than adapting the two with something like a LoveJoy torque coupler, but it will be more elegant and perform better at high RPMs. The shaft and adapter plate will need to be perfect so that I don't mess up the bearings in motor or transmission.

I'm double checking the dimensions of the transmissions's input shaft now. I'm editing the model in SolidWorks and will have the final driveshaft built for me by Mitchell Differential in Worcester, MA. Although the Center of Design at Hampshire College, where I work, is extremely well equipped, I will entrust this important job to a professional with nicer tools than I have.

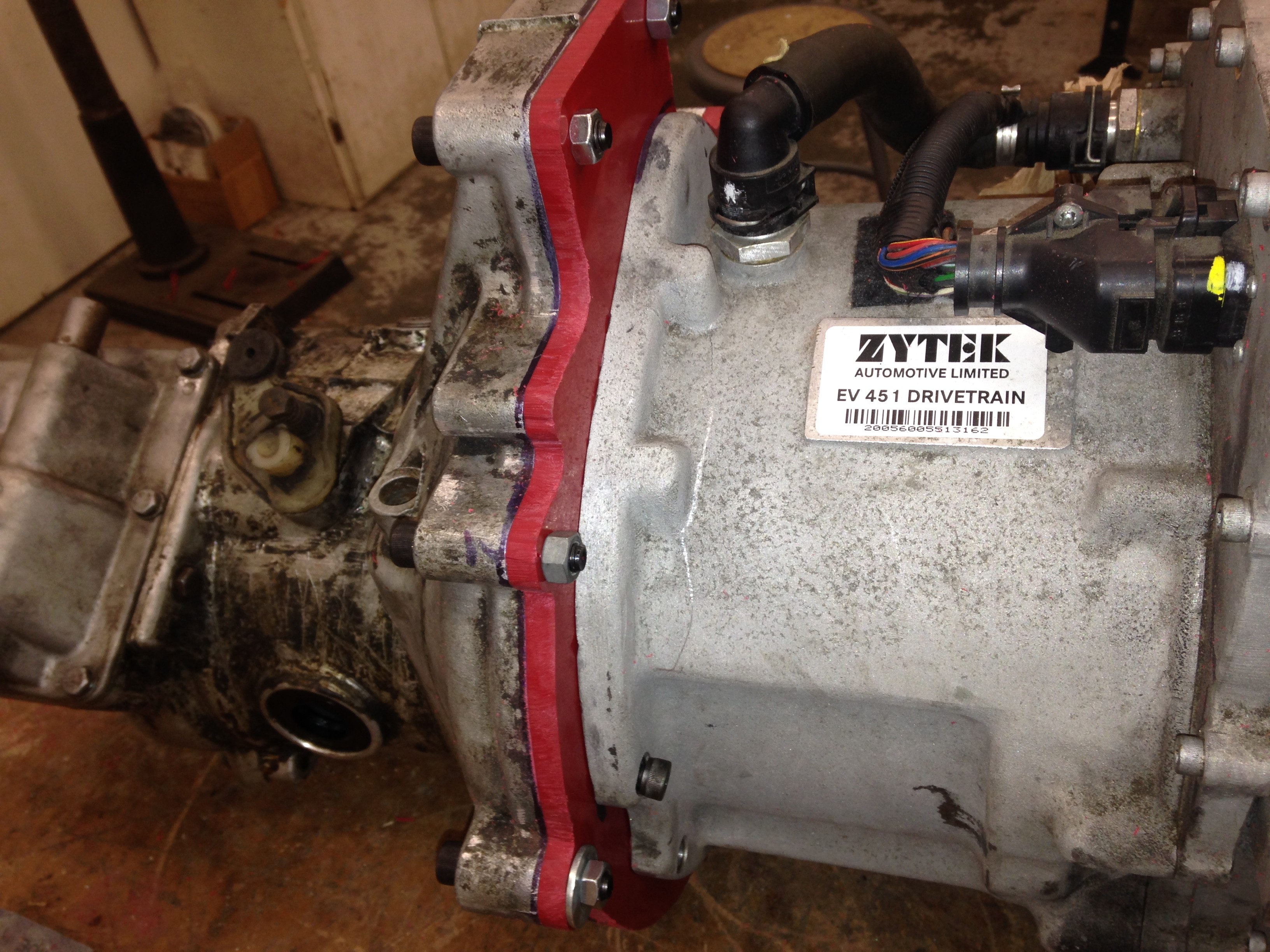

The picture below shows my Zytek motor out of an electric Smart Car, the adapter plate in red plastic, and my dirty old transmission.

Adam Curtis

Adam Curtis

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.