(See the last log for difficulties I'm experiencing using this as a DC motor-driver...)

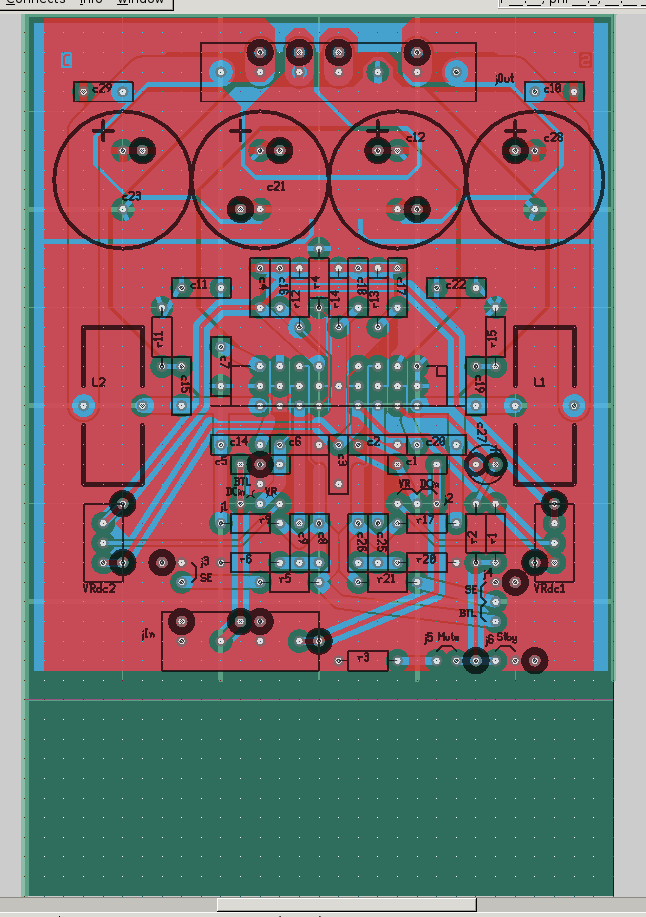

This is a board designed very-heavily based on the example in the datasheet for this TDA7490 Class-D audio amplifier... Modified for .1in spacing and a few other things useful for my testing-needs... jumpers for switching between BTL and single-ended mode, jumpers for DC-coupled vs AC-coupled input vs Potentiometer-voltage-divider input... Also needed to keep in mind having traces on top

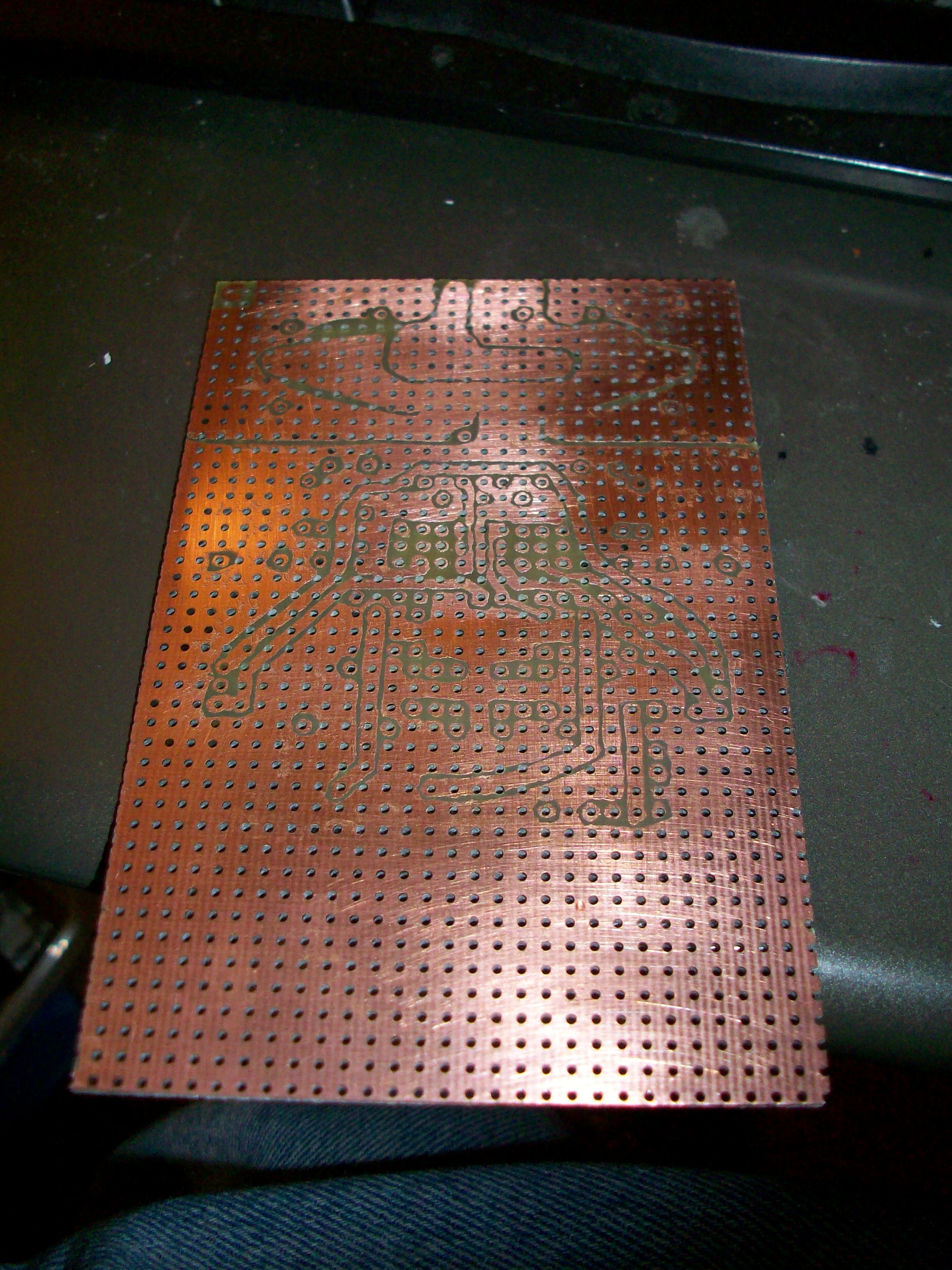

In an earlier log-entry I showed the PCB drawing I did in software before-hand... Here's the latest...

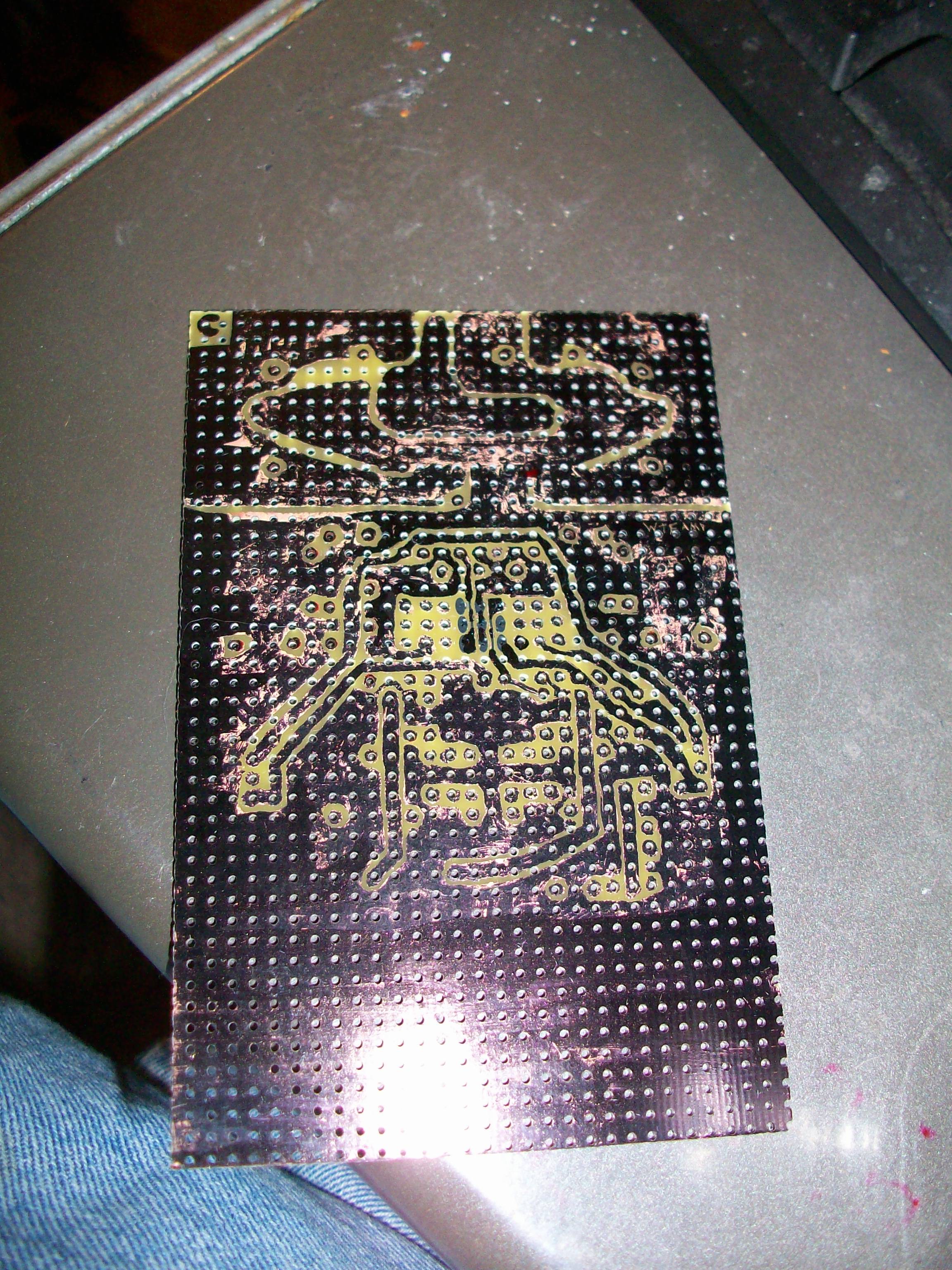

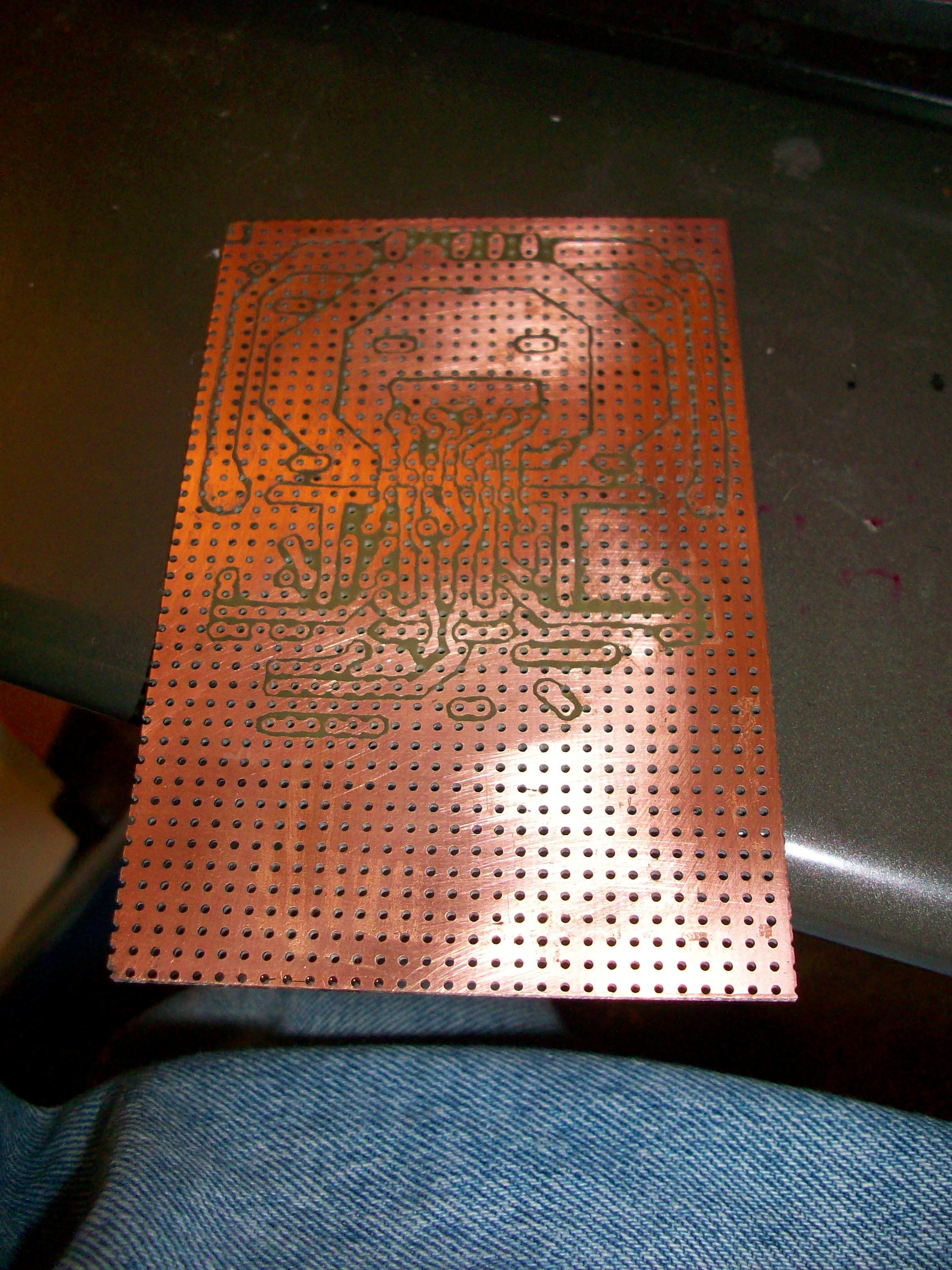

The vast-majority of this PCB was hand-drawn with a permanent-marker (handy to have those predrilled holes on a grid for matching front-to-back!). But some of the really tight spacing (traces between pins) was handled with rub-on etch-resist stencils(?).

I think this might be the first PCB I've etched in over a decade(?!) Was a lot easier than I remembered, and was surprised at how much resolution you can get with little more than a permanent marker!

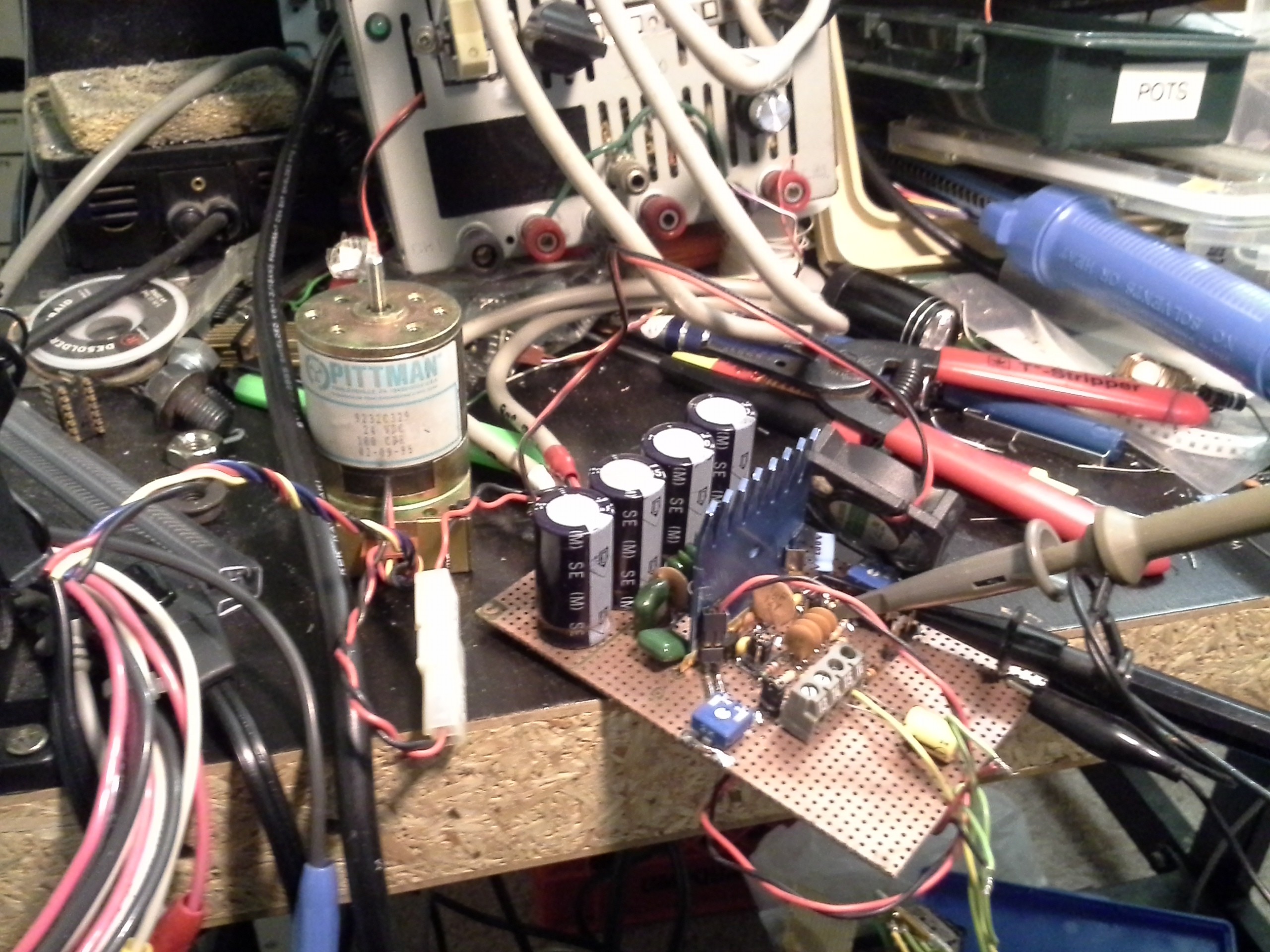

So, it works, it works with a DC input and I can vary the speed/direction of the motor by adjusting a potentiometer-voltage-divider... But it seems to be overheating (or something) causing it to go into "mute" mode briefly from time-to-time. (see the last log for ramblings on the matter).

Eric Hertz

Eric Hertz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Wow that etching turned out well! Maybe I need to buy some ferric chloride.

Are you sure? yes | no

It's one of those things, yahknow... I got used to professionally-manufactured and started to think they've got massively-specialized techniques... but if I measured some of the (unintentional) closer traces/spaces I bet there's some 10-mil or less going on in there... A bit more precision than a permanent-marker, and (surprising to me) that resolution could probably be harnessed by someone like me. (I suppose I could probably find a bunch of instructables)

Are you sure? yes | no

I've been using X-acto knives to carve traces lately. Great for fine pitch stuff. This looks like it's a better way to get curvy lines though!

Are you sure? yes | no

The knife-method for peeling up copper...?

Are you sure? yes | no

Yeah, takes a decent bit of pressure but I basically do one cut at ~+30 degrees and one at -30 degrees from vertical, creating a tiny V-shaped canyon between traces. Works well enough for 0.8mm pitch stuff (0.65 pitch is possible but _ridiculously tedious_), but takes a long time and looks pretty sloppy.

Are you sure? yes | no

Gotta see some of your knife-work!

Are you sure? yes | no

I think I can see a cartoon face puking its guts out in that layout. Lovely! :) I have't see any pre drilled copper clad boards before.

Are you sure? yes | no

LOL Gross. I saw the Space-Invaders, I think it was @zakqwy who pointed it out. But puking-guts Wee!

I think I bought these by mistake long ago thinking they were breadboards... They're marked Digikey B3426D-ND "Injectorall Cat No. B3426D" Was definitely planning on using regular-ol' copper-clad, but these were sitting in the same box. Nice surprise, kinda handy.

Are you sure? yes | no