My HDD Caddy arrived. It was a little different from the one mentioned in the previous one. To save costs, it seems they had switched the caddy from aluminium to injection molded plastic. It did make a difference.

This should have been a breeze but it turned out not so much, due to two reasons:

- The face plate was a little wobbly on the older optical drive because one of the retainer tabs broke. So I had to super glue the face bezel to the new caddy. Point of no return 1.

- The M2.5 screws attaching an L-bracket to the drive (so that it can be secured to the laptop chassis) were too short to reach the threads. This would have not been an issue had the caddy had an all-metal chassis but the plastic came in the way and had holes bigger than 2.5mm. Bummer.

- However, the holes on the plastic were just of the right size for a M3 screw. So with a 3mm drill bit I made the holes on the L-bracket larger and then tightened the screws in with force. Point of no return 2.

After all this, for a test I connected another 500GB HDD I had and booted up the system. Everything looked good. As I side effect I also noticed that the HDD in the drive caddy ran cooler than my primary HDD. It was about 5-6 degrees cooler (10 deg Fahrenheit) than the hard drive in the main drive bay, with the laptop not being cooled on a pad the HDD would be so hot as if it'd go toast (> 40 degrees C).

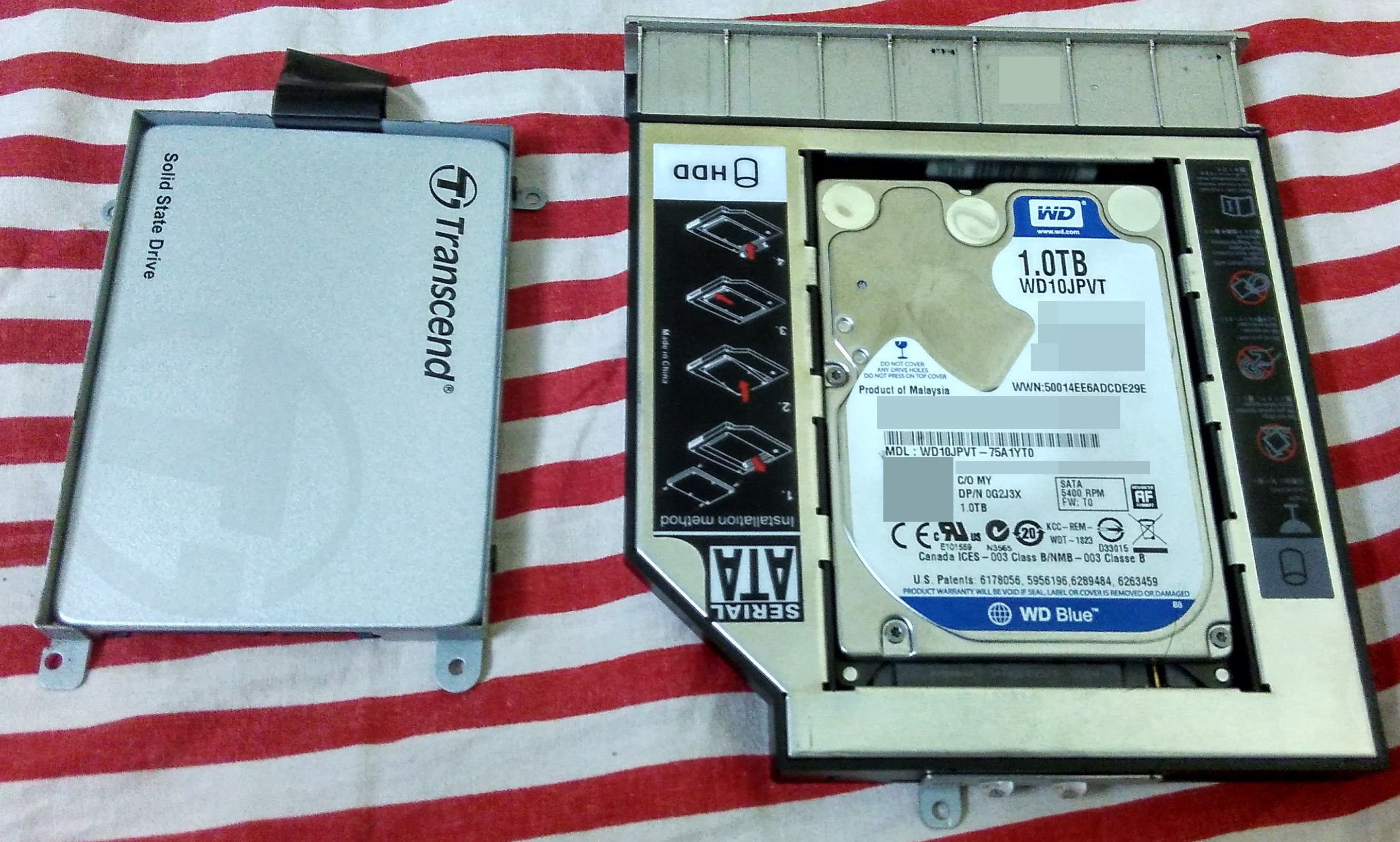

So the drive swap would now be a two-way swap - my existing 1 TB drive went into the caddy while the SSD would live in the main drive bay. (you can see the bracket held onto the caddy, bottom center).

Putting the SSD where the HDD originally was:

Looks good so far, dmesg tells me that the drive is good at 6 Gbps. awesome! Although I haven't installed anything on the SSD yet but I'm looking forward to very soon.

Kumar, Abhishek

Kumar, Abhishek

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.