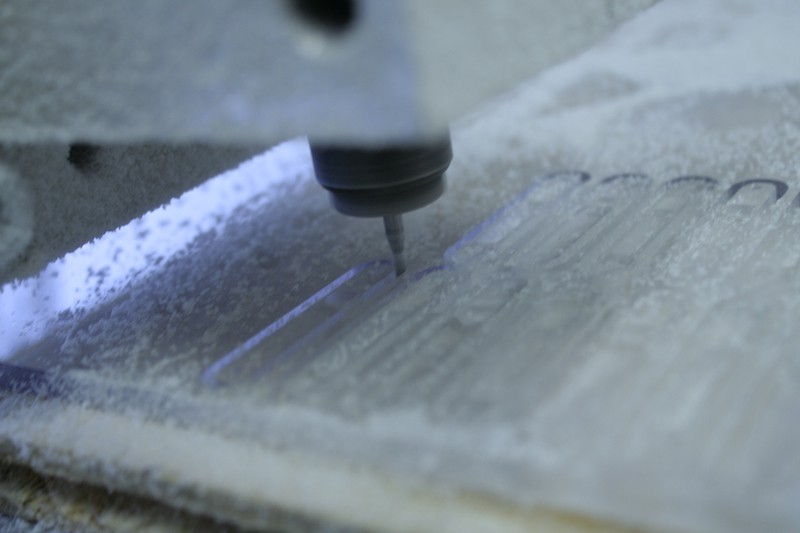

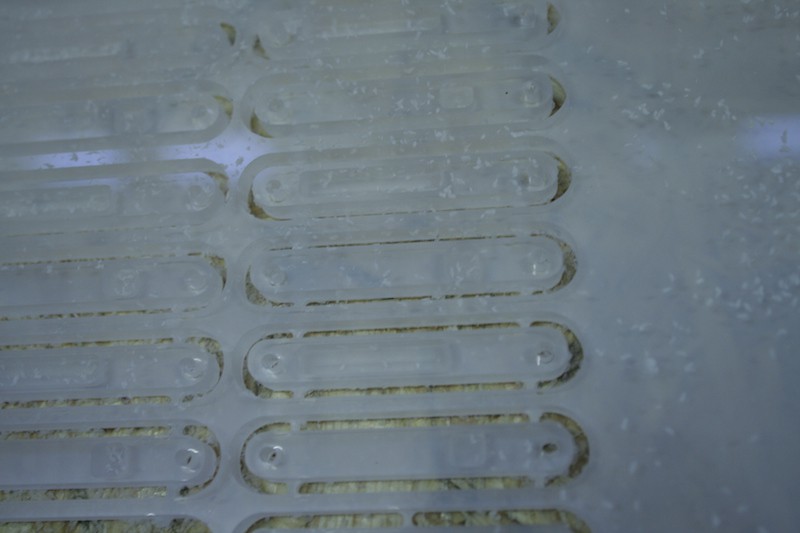

Yesterday, I was able to mill the polycarbonate LED covers for the heated beds on our mill at Attraktor makterspace. They turned out way better than I hoped. The necessary screws and nuts haven't yet been delivered, but once they arrive, the parts for the first beta test kits are complete.

Cutting polycarbonate

Polycarbonate is a tough and temperature resistant material and can be processed similar to wood. Large cutting teeth on normal and circular saw blades usually give good results. On the mill, you'd probably use a not too small single tooth acrylic or similar milling bit.

But those LED covers are quite tiny and I wanted the finish of the milling pockets as nice as possible. Since our mill doesn't feature a tool changer, I also wanted to mill them all in one go, which means the milling bit cannot be larger than the small screw holes (ø 2.2 mm). So I contacted the people from vhf camfacture to help me out with the right milling bit and parameters. They're very dedicated and supportive people and their unique milling bits are worth the money. Eventually, a ø 2 mm polished flute single tooth milling bit was used.

I had to experiment a bit with the right size of the attachment bridges. Polycarbonate is quite tough, so it definitely needs strong bridges, however, they are also hard to remove.

So, that worked. I was in a hurry and later on found the photo below came out blurry, but I'll soon post better pictures of the completed kits anyway!

Moritz Walter

Moritz Walter

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.